7

HELPFUL TIPS & SUGGESTIONS

STORING YOUR ENGINE

Storage Preparation

Proper storage preparation is essential for keeping your engine

trouble-free and looking good. The following steps will help to keep

rust and corrosion from impairing your engine’s function and

appearance, and will make the engine easier to start when you use it

again.

Cleaning

If the engine has been running, allow it to cool for at least half an hour

before cleaning. Clean all exterior surfaces, touch up any damaged

paint, and coat other areas that may rust with a light film of oil.

NOTICE

Using a garden hose or pressure washing equipment can force water

into the air cleaner or muffler opening. Water in the air cleaner will

soak the air filter, and water that passes through the air filter or muffler

can enter the cylinder, causing damage.

Fuel

Gasoline will oxidize and deteriorate in storage. Deteriorated gasoline

will cause hard starting, and it leaves gum deposits that clog the fuel

system. If the gasoline in your engine deteriorates during storage, you

may need to have the carburetor, and other fuel system components,

serviced or replaced.

The length of time that gasoline can be left in your fuel tank and

carburetor without causing functional problems will vary with such

factors as gasoline blend, your storage temperatures, and whether the

fuel tank is partially or completely filled. The air in a partially filled fuel

tank promotes fuel deterioration. Very warm storage temperatures

accelerate fuel deterioration. Fuel problems may occur within a few

months, or even less if the gasoline was not fresh when you filled the

fuel tank.

Fuel system damage or engine performance problems resulting from

neglected storage preparation are not covered under

the Distributor’s

Limited Warranty

You can extend fuel storage life by adding a gasoline stabilizer that is

formulated for that purpose, or you can avoid fuel deterioration

problems by draining the fuel tank and carburetor.

ADDING A GASOLINE STABILIZER TO EXTEND FUEL

STORAGE LIFE

When adding a gasoline stabilizer, fill the fuel tank with fresh gasoline.

If only partially filled, air in the tank will promote fuel deterioration

during storage. If you keep a container of gasoline for refueling, be

sure that it contains only fresh gasoline.

1. Add gasoline stabilizer following the manufacturer’s instructions.

2. After adding a gasoline stabilizer, run the engine outdoors for 10

minutes to be sure that treated gasoline has replaced the untreated

gasoline in the carburetor.

3. Stop the engine.

DRAINING THE FUEL TANK AND CARBURETOR

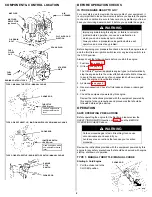

1. Use a siphon pump (commercially available) and siphon the fuel

out of the fuel tank into an approved gasoline container.

2. Place an approved gasoline container below the carburetor, and

use a funnel to avoid spilling fuel.

3. Loosen the carburetor drain screw. and drain the carburetor into an

approved gasoline container. After draining is completed, tighten

the carburetor drain screw.

Engine Oil

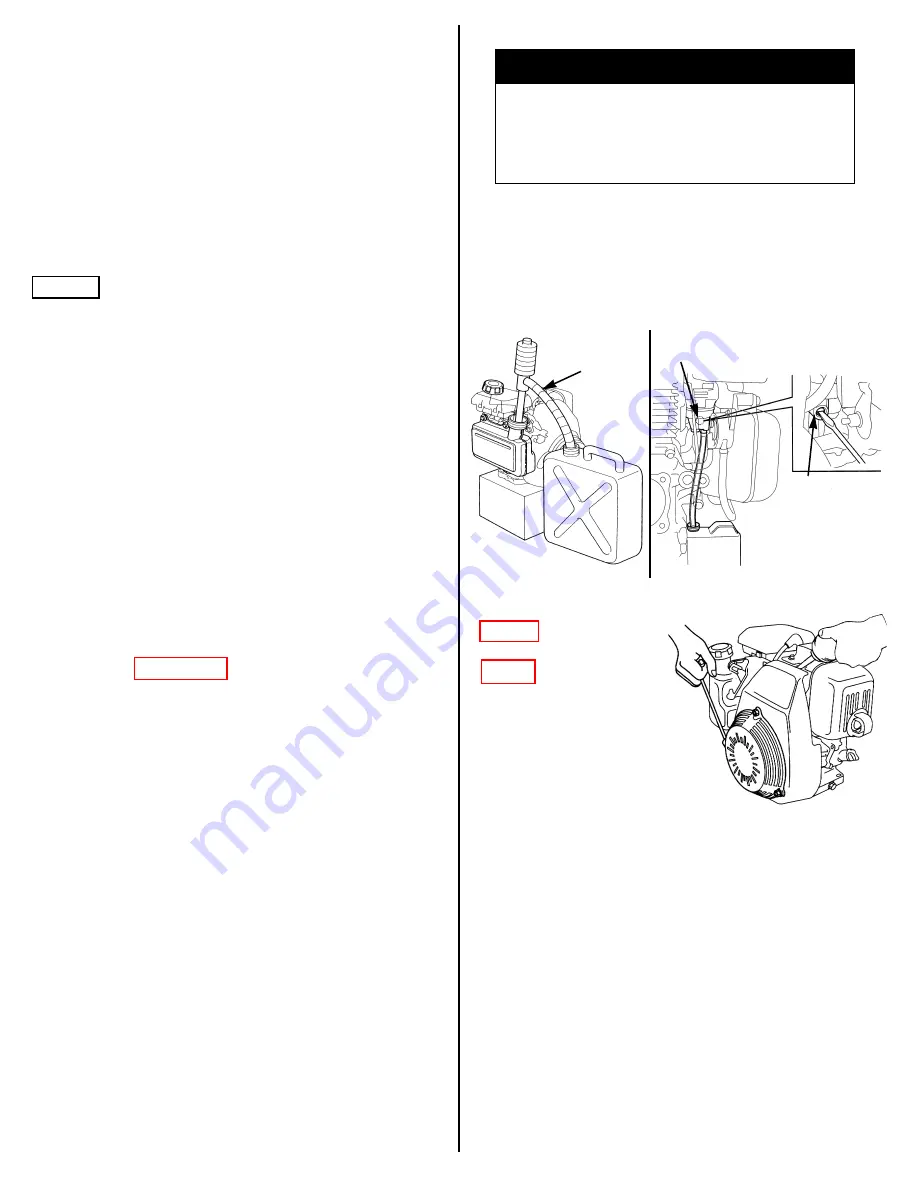

1. Change the engine oil (see

2. Remove the spark plug (see

3. Pour a tablespoon (5 - 10 cc)

of clean engine oil into the

cylinder.

4. Pull the recoil starter several

times to distribute the oil.

5. Reinstall the spark plug.

WARNING

Gasoline is highly flammable and explosive, and you can

be burned or seriously injured when handling fuel.

• Stop engine and keep heat, sparks, and flame away.

• Refuel only outdoors.

• Wipe up spills immediately.

SIPHON PUMP

(COMMERCIALLY

AVAILABLE)

FLOAT BOWL

DRAIN SCREW