8

Storage Precautions

If your engine will be stored with gasoline in the fuel tank and

carburetor, it is important to reduce the hazard of gasoline vapor

ignition. Select a well-ventilated storage area away from any appliance

that operates with a flame, such as a furnace, water heater, or clothes

dryer. Also avoid any area with a spark-producing electric motor, or

where power tools are operated.

If possible, avoid storage areas with high humidity, because that

promotes rust and corrosion.

Keep the engine level in storage. Tilting can cause fuel or oil leakage.

With the engine and exhaust system cool, cover the engine to keep

out dust. A hot engine and exhaust system can ignite or melt some

materials. Do not use sheet plastic as a dust cover. A nonporous cover

will trap moisture around the engine, promoting rust and corrosion.

Removal From Storage

Check your engine as described in the

BEFORE OPERATION

CHECKS

section of this manual (see page 2).

If the fuel was drained during storage preparation, fill the tank with

fresh gasoline. If you keep a container of gasoline for refueling, be

sure it contains only fresh gasoline. Gasoline oxidizes and deteriorates

over time, causing hard starting.

If the cylinder was coated with oil during storage preparation, the

engine will smoke briefly at startup. This is normal.

TRANSPORTING

Keep the engine level when transporting to reduce the possibility of

fuel leakage.

TAKING CARE OF UNEXPECTED PROBLEMS

TECHNICAL & CONSUMER INFORMATION

TECHNICAL INFORMATION

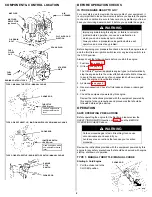

Serial Number Location

Record the engine serial

number in the space

below. You will need this

information when

ordering parts and when

making technical or

warranty inquiries.

Engine serial number:

GCAAA–

___ ___ ___ ___ ___ ___ ___

Engine type: ___ ___ ___ ___

Carburetor Modifications for High Altitude Operation

At high altitude, the standard carburetor air-fuel mixture will be too rich.

Performance will decrease, and fuel consumption will increase. A very

rich mixture will also foul the spark plug and cause hard starting.

Operation at an altitude that differs from that at which this engine was

certified, for extended periods of time, may increase emissions.

High altitude performance can be improved by specific modifications to

the carburetor. If you always operate your trimmer at altitudes above

5,000 feet (1,500 meters), have your servicing dealer perform this

carburetor modification. This engine, when operated at high altitude

with the carburetor modifications for high altitude use, will meet each

emission standard throughout its useful life.

Even with carburetor modification, engine horsepower will decrease

about 3.5% for each 1,000-foot (300-meter) increase in altitude. The

effect of altitude on horsepower will be greater than this if no

carburetor modification is made.

NOTICE

When the carburetor has been modified for high altitude operation, the

air-fuel mixture will be too lean for low altitude use. Operation at

altitudes below 5,000 feet (1,500 meters) with a modified carburetor

may cause the engine to overheat and result in serious engine

damage. For use at low altitudes, have your servicing dealer return the

carburetor to original factory specifications.

ENGINE WILL NOT

START

Possible Cause

Correction

1. Check control positions

Choke open.

Pull the choke to the

CLOSED position unless

the engine is warm.

Ignition switch OFF.

the SLOW or FAST

position (p.3).

lever to the ON position

(p. 3).

switch to the ON position

(p. 4).

2. Check engine oil level.

Engine oil level low (Oil Alert

models).

Fill with the recommended

oil to the proper level (p. 5).

3. Check fuel.

Out of fuel.

Refuel.

Bad fuel; engine stored

without treating or draining

gasoline, of refueled with bad

gasoline.

Drain the fuel tank and

carburetor (p. 7). Refuel

with fresh gasoline.

4. Remove and inspect

spark plug.

Spark plug faulty, fouled, or

improperly gapped.

Spark plug wet with fuel

(flooded engine).

Dry and reinstall spark

plug. Start engine with

throttle lever in FAST

position (choke in OPEN

position).

5. Take engine to an

authorized Honda

servicing dealer, or refer

to shop manual.

Fuel filter clogged, carburetor

malfunction, ignition

malfunction, valves stuck,

etc.

Replace or repair faulty

components as necessary.

ENGINE LACKS

POWER

Possible Cause

Correction

1. Check air filter

Filter clogged.

Clean or replace the filter

(p. 6).

2. Check fuel.

Bad fuel; engine stored

without treating or draining

gasoline, of refueled with bad

gasoline.

Drain the fuel tank and

carburetor (p. 7). Refuel

with fresh gasoline.

3. Take engine to an

authorized Honda

servicing dealer, or refer

to shop manual.

Fuel filter clogged, carburetor

malfunction, ignition

malfunction, valves stuck,

etc.

Replace or repair faulty

components as necessary.

SERIAL

NUMBER

AND TYPE

LOCATION

SERIAL NUMBER

TYPE