4.

ADJUSTMENTS AND TUNING

This chapter deals with the adjustments to be made to remedy the more frequent performance failures and are

usually resolved by quick checks and tunings.

The timings for these items of work are shown in chapter 1.6.

4.1

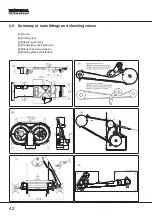

Blade engagement

The blades are run from the engine using a trapezoidal the blades are engaged by means of a tightener that is

operated by a lever.

The length of the belt and cable may change after some time

in use, causing irregular operation indicated by the following

signs:

1. belt slipping = belt or cable stretched

2. difficult to disengage, with the blades continuing to run =

belt shortened

In both cases the tensionner needs to be adjusted.

The difficulty in disengaging can also be caused by

grass-cuttings that have accumulated in the end position of the

control lever. Should this be the case, first clean the lever joint

otherwise the tensionner could be incorrectly adjusted.

a. Cleaning the lever joint

1. This operation can be carried out via an inspection door

and can also be made easier by removing the conveyor

(see

5.3).

2. Having reached the lever joint [1], remove the accumulated

grass cuttings [2] which stop the lever from reaching the

end.

b. Tensionner adjustment

1. Remove the upper protection cover [3] in those models

where this is supplied.

2. With the cutting plate in its lowest position, find the

tightener

[4] which is located under the left footboard.

Turn the nuts until the spring reaches the appropriate

length with the blades engaged:

[7]

HF2213

122 ¸ 124 mm

HF2218

94 ¸ 95 mm

3. When the adjustment has been made, check that the brake

lining [5] is working properly. It must stop the blades within

5 seconds of disengaging the blades.

4. Should this not be the case, check that the brake lining [5]

is not worn and/or that the spring [6] is not too taut.

46