6.7

Dismantling rear wheel axle

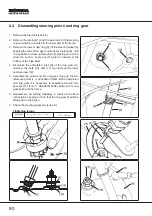

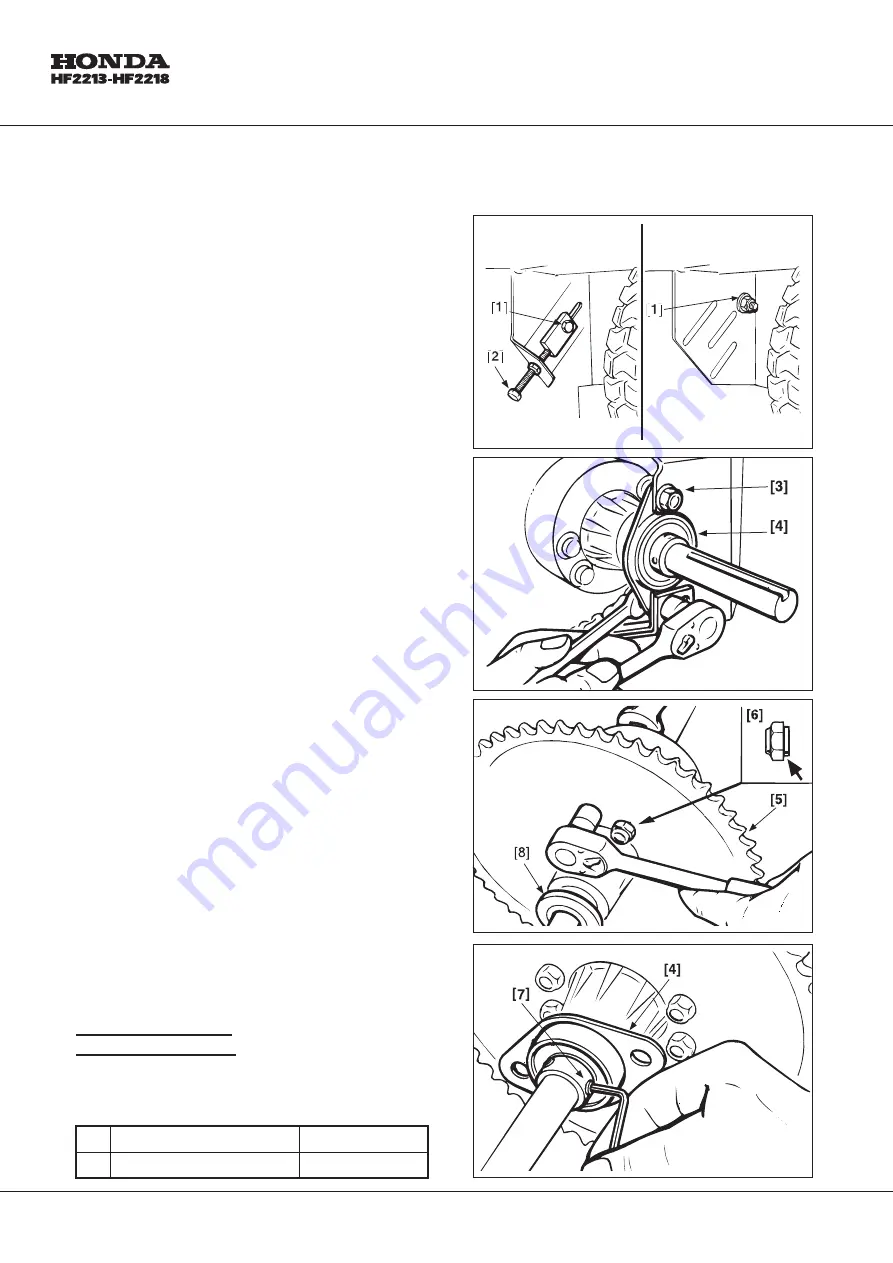

1. Place the Lawn-Tractor in the vertical position (see

2.4).

2. Remove the rear wheels (see 6.1.B)

3. Untighten the chain tensioning pin [1] and the adjusting

screw [2] (up to serial n° 8611666).

From serial n° 8611667, with the introduction of the new

chain tightener, only the external nut (1a) need to be

loosened to free the chain.

4. After unscrewing the six nuts [3] securing the flanges of the

three bearings [4] and removing the chain from the ring

gear, the rear axle can be removed so that the necessary

checks and replacements can be made.

a. Dismantling the ring gear

The ring gear [5] is attached to the differential by means of four

nuts [6] which must be unscrewed without untightening the

screw heads holding the two sections of the differential

together.

When fitting, use a strong type lockwire.

NOTE:

The ring gears are fitted with seats to house centring

devices provided on the nuts [6]. This ring gear and the nuts

ensure precision during assembly.

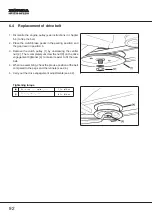

b. Replacement of bearings

The bearings are secured axially to the half-axles by means of

two clamping collars [7].

When fitting, it is advisable to allow the bearings to slide freely

on the shaft: fit the chain on the ring gear and on the gearbox

pinion, reinstall the bearing flanges and their corresponding

screws without locking them.

NOTE:

Do not forget the two anti-dust bushes [8] located on

the sides of the differential. They must be fitted by positioning

the concave section towards the inside.

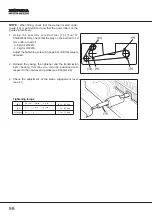

1. After aligning the chain, lock all the bearings and the flange

nuts, and turn the shaft by hand in order to check that it

rotates freely.

2. Before remounting the wheels, ensure that the slots of the

splines are without rough edges and that the splines are

not misshapen (see 6.1).

3. Up to serial n° 8611666: reset the chain tension (see 4.3).

From serial n° 8611667: correctly re-assemble the chain

tension (see 6.12).

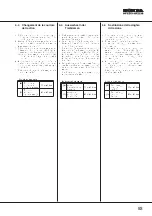

Tightening torques

[3]

Bearing flange fixing nuts

30 ÷ 35 Nm

[5]

Ring gear fixing nuts

28 ÷ 30 Nm

100