6.

REPAIRS

This chapter deals with all the more complex work connected with the replacement or repair of malfunctioning or

worn parts.

The descriptions proceed by necessity in a logical way and can include operations not specifically connected to a

particular type of repair.

In this case, careful reading of the entire procedure can help you omit all those operations not connected with the

case in hand without, however, overlooking anything that may be necessary.

Timings for these items of work are shown in chapter 1.6.

6.1

Replacement of tyres and wheels

NOTE:

The tyres used are tubeless. Consequently, if a tyre

is punctured, it must be repaired by a specialized tyre repairer

in accordance with the procedures prescribed for this type of

tyre.

NOTE:

After replacing one or more tyres, the cutting deck

should be checked to ensure that it is parallel (see 4.4).

·

Replace deformed wheel rims in order to ensure

satisfactory performance of the tyres.

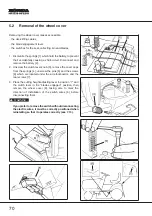

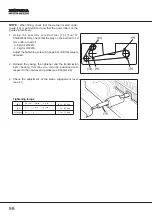

a. Front wheels

1. The front wheels are held by retaining ring [1] that can be

removed with a screwdriver.

2. When fitting, smear the pin with grease and replace the

shouldered washer [2].

b. Rear wheels.

NOTE:

If a wheel is jammed on the axle, use a penetrating oil

spray, directing the jet towards the keying groove.

When re-assembling, smear grease over the shaft, which will

help the next time the wheel needs to be removed.

Up to serial n° 8700563:

1. The rear wheels are directly attached to the differential axle

shaft with a spline [3] and held by a screw [4] with its nut

[5].

2. When fitting, first check that the key and its seat on the axle

are in good condition and, then, smear grease on the shaft,

insert the key and push fully home until it clears the hole for

the screw [4].

3. Put in the screw [4] and lock the nut [5] to the amount shown.

!

WARNING :

84