6.4 DISMANTLING AND REPLACEMENT

6.4.1 Oil engine

Drain the oil while the engine is still hot to ensure quick, complete

draining.

Remove the filler cap with the dipstick and place a sheet of cardboard

or something similar under the drain tube to prevent the oil from

dripping onto the machine’s chassis.

Unscrew plug (1); when refitting the plug take care over the position

of the inner gasket.

Fill with the recommended oil until the upper limit of the dipstick is

reached (

5.3.3). Screw the dipstick cap back on.

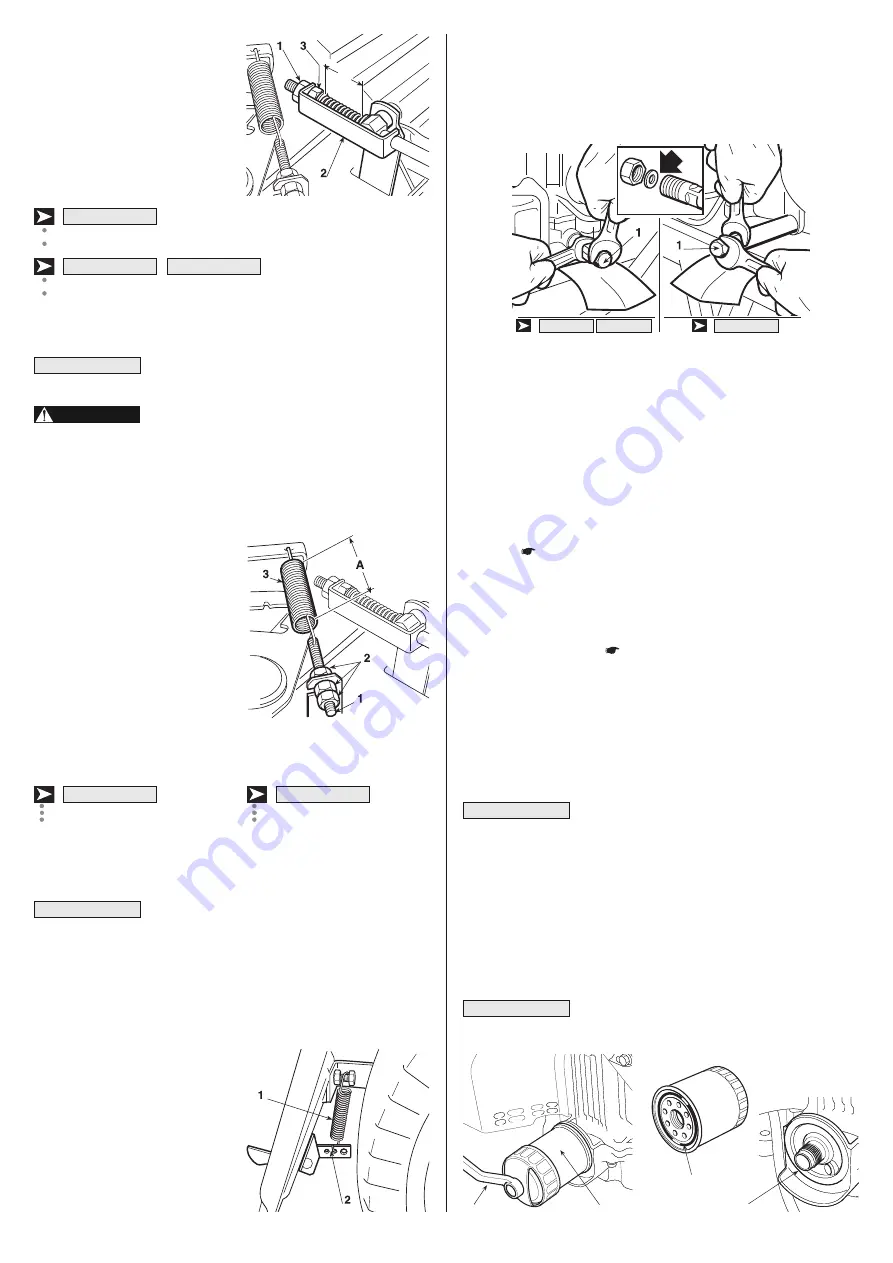

6.4.2 Oil filter change (only

HF2622H

◊

••

)

1. Drain the engine oil (

6.4.1).

2. Remove the oil filter (1) with a filter wrench (2) and let the re-

maining oil drain out. Discard the oil filter.

3. Clean the filter base (3).

4. Coat the new O-ring (4) on the new filter with clean engine oil.

5. Install the new oil filter on the filter base and tighten it by hand un-

til the O-ring seats against the filter base.

6. Tighten the oil filter to the specified torque (12 Nm - 1.20 kgm).

Use only a Honda genuine oil filter or a filter of

equivalent quality specified for your model.Using the wrong Honda

filter or a non-Honda filter which is not of equivalent quality may

cause engine damage.

7. Pour the specified amount of recommended oil into the engine.

Start the engine and check the filter for leaks.

8. Stop the engine and recheck the oil level. If necessary, add oil to

bring it up to the proper level.

Ask your authorized Honda dealer for advice on

the filter wrench (special tool).

NOTE

IMPORTANT

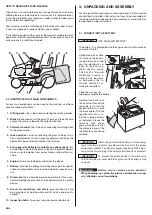

Access for making this adjustment

is by taking off the inspection hatch

on the tunnel beneath the seat.

Loosen the nut (1) which holds the

bracket (2) and turn the nut (3) un-

til the length of the spring is:

A

= 47,5 - 49,5 mm

B

= 45 - 47 mm

measured inside the washers.When the adjustment has been made,

tighten the nut (1).

Do not screw below these levels to avoid over-

loading the brake unit.

If the brake still does not work properly even

after this adjustment, immediately contact your Dealer . DO

NOT ATTEMPT OTHER WORK ON THE BRAKE THAN DE-

SCRIBED HERE.

6.3.5 Adjusting the tension of the drive belt

If you should notice that forward

drive power has dropped, it will be

necessary to adjust the tension of

stretcher’s spring to return to top

operational conditions.

Access for making this adjustment

is by taking off the inspection hatch

on the tunnel beneath the seat.

Loosen the locking nuts (2) and

tighten or loosen the screw (1) as

much as necessary for a length

«A» of the spring (3) of:

A

= 129 - 131 mm

A

= 109 - 111 mm

measured to the outside of the end of the spring. When the adjust-

ment has been made, tighten the nuts (2).

When replacing the belt, take great care when us-

ing for the first few times as engagement may be sudden until the

belt is sufficiently run in.

6.3.6 Adjustment of the spring of the pawl for hooking

the grass-catcher

If the grass-catcher tends to jump

about and to open up when going

over rough ground, or if it is difficult

to hook back on after being emp-

tied, the tension of the spring will

need to be adjusted(1).

Change the hooking point by using

one of the holes (2) until the re-

quired result is achieved.

NOTE

HF2315SB•

HF2•••H

♦

•

WARNING!

IMPORTANT

HF2•••HT•

HF2•••HM•

HF2•••SB•

18

EN

1

2

3

4

HF2622

◊

••

HF24••

◊

••

HF23••

◊

••

A

B

B