5. After the spark plug is seated, tighten with a spark plug wrench (1)

to compress the washer.

When installing a new spark plug, tighten 1/2 turn

after the spark plug seats to compress the washer. When rein-

stalling a used spark plug, tighten 1/8 1/4 turn after the spark plug

seats to compress the washer.

The spark plugs must be securely tightened. Im-

properly tightened spark plugs can become very hot and may

damage the engine.

6.4.6 Replacing wheels

Stop the machine on a flat surface

and put a block under a load-bear-

ing part of the frame on the side

that the wheel is to be changed.

The wheels are held by a snap ring

(1) which can be eased off with a

screwdriver.

The rear wheels are directly coupled to the axle shaft and fastened

by a key that forms part of the wheel's hub.

Should you substitute one or both rear wheels,

ensure that they are of the same diameter, and check that the cut-

ting deck is horizontal to prevent an uneven cut.

Before re-fitting a wheel, smear some grease on

the axle and carefully re-fit the snap ring (1) and washer (2).

6.4.7 Replacing or repairing tyres

The tyres are of the «Tubeless» type and therefore all replacement

or repairs will have to be carried out by a tyre-repair expert in accor-

dance with the methods for this kind of tyre.

6.4.8 Replacing bulbs (in models with lights)

The bulbs (10W) have a bayonet fitting and are installed in the bulb

holder which can be taken out by turning it anti-clockwise, using

pliers.

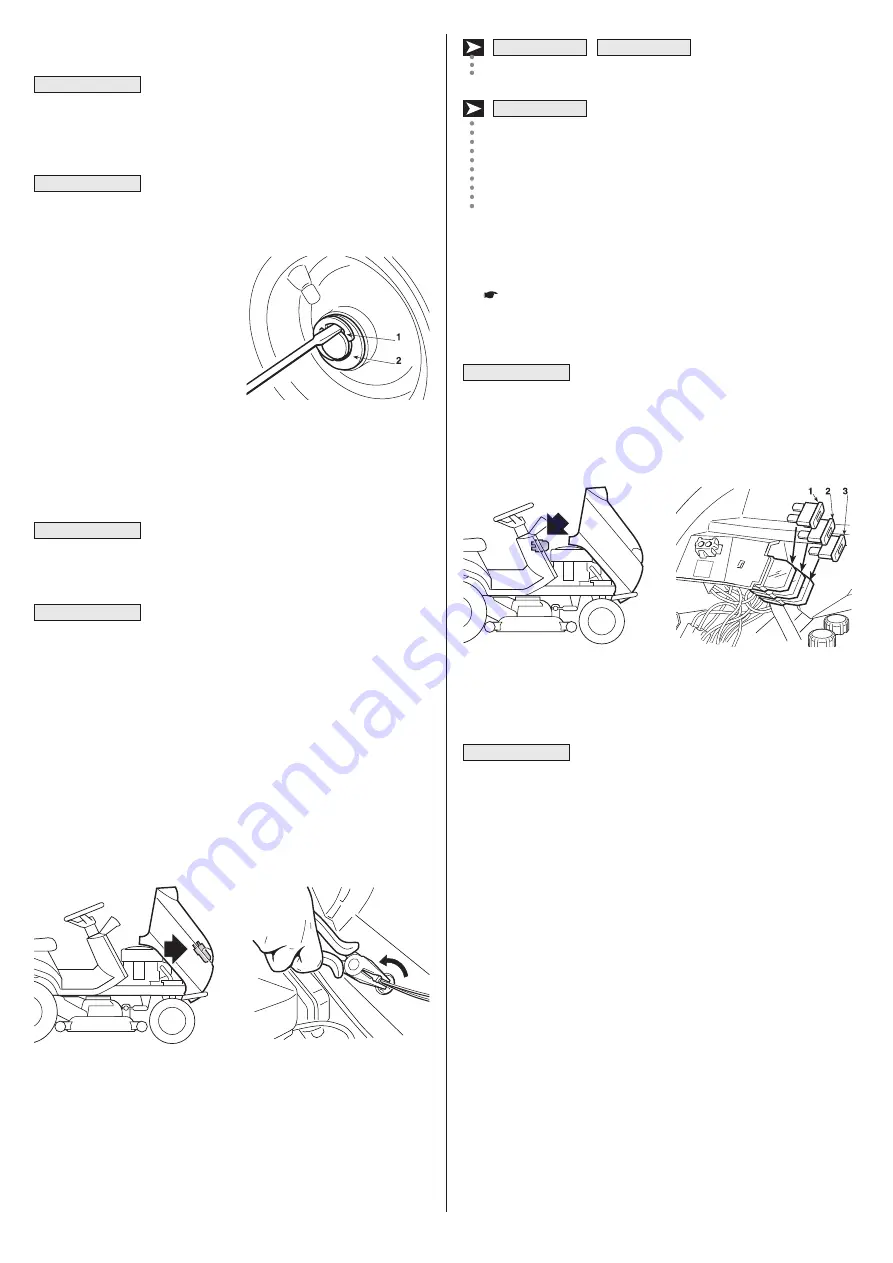

6.4.9 Replacing a fuse

A few fuses of various capacities are envisaged on the machine.Their

functions and features are given in the following table:

1 - 10 Amps - (Red)

protection of the main circuits

and power circuits of the

electronic card;

IMPORTANT

NOTE

IMPORTANT

NOTE

2 - 15 Amps - (Blue)

protection of the recharge

circuit;

2 - 15 Amps - (Blue)

protection of the recharge

circuit;

3 - 10 Amps - (Red)

protection of the grass-catcher

tipping control circuit.

– When the fuse blows (1) the machine stops and all the lights on the

dashboard go out.

– The battery pilot lamp turns on in models provided with it

(

4.11.f) when the fuse (2) trips.

– Tripping of the fuse (3) prevents the control motor of the grass-

catcher’s tipping to operate.

A blown fuse must always be replaced by one of

the same type and rating, and never with one of another rating.

If you cannot find eliminate the causes of the tripping, consult your

Dealer.

6.4.10 Replacing belts

Replacing belts is quite a complicated process of dismantling and

subsequent adjustment and must only be carried out by your Dealer.

Replace the belts as soon as they show obvious

signs of wear! ALWAYS USE GENUINE REPLACEMENT BELTS!

NOTE

IMPORTANT

HF2622H••

HF23••

◊

••

HF24••

◊

••

7. ENVIRONMENTAL PROTECTION

Environmental protection should be a priority of considerable impor-

tance when using the machine, for the benefit of both social coexis-

tence and the environment in which we live.

– Try not to cause any disturbance to the surrounding area.

– Scrupulously comply with local regulations and provisions for the

disposal of waste materials after sawing.

– Scrupulously comply with local regulations and provisions for the

disposal of oils, petrol, damaged parts or any elements which have

a strong impact on the environment; this waste must not be dis-

posed of as normal waste, it must be separated and taken to spec-

ified waste disposal centres where the material will be recycled.

– At the time of decommissioning, do not pollute the environment

with the machine, hand it over to a disposal centre, in accordance

with the local laws in force.

20

EN