5.2 WHY THE SAFETY DEVICES CUT IN

The safety devices work in two ways:

– they prevent the engine from starting if all the safety requirements

have not been met;

– they stop the engine if even just one of the safety requirements is

lacking.

To start the engine, in all cases it is necessary that:

– the transmission is in “neutral”;

– the blades are not engaged;

– the operator is seated or the parking brake is engaged.

The engine stops when:

– the operator leaves his seat when the blades are engaged;

– the operator leaves his seat when the transmission is not in

“neutral”;

– the operator leaves his seat with the transmission in “neutral” but

without engaging the parking brake;

– the grass-catcher is lifted or the stone-guard is removed when the

blades are engaged;

– the reverse gear is engaged with the blades engaged.This can be

avoided by keeping the push-button 4.7 pressed.

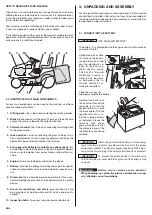

The table below shows various operating conditions,

highlighting

why the safety device shuts down the engine.

5.3 PRELIMINARY OPERATIONS BEFORE STARTING WORK

Before starting to work it is necessary to carry out several checks and

operations to ensure that the work gives the best results and is done

in maximum safety.

5.3.1 Seat adjustment

To adjust the seat position, the

four fixing screws (1) must be

loosened. Move the seat along

the support slots.

When you find the desired posi-

tion, tighten the four screws (1).

The sliding seat can be adjusted

onto six different positions.

The position is changed by

pulling up the handle (1) and

sliding the seat until it is locked

into the desired position.

HF2•••H

♦

•

HF2315SB•

5.3.2 Tyre pressure

Unscrew the hubcaps and connect

the valve caps to a compressed air

line with a gauge.

Proper tyre pressure levels arevital

for perfect alignment of the cutting

deck and thus mows evenly.

The pressures are:

FRONT

1.5 bar (13 x 5.00-6)

1.0 bar (15 x 5.00-6)

REAR

1.2 bar

5.3.3 Filling with oil and fuel

Use oil SAE 10W30 and Petrol Unleaded Euro 95.

Running the engine with an insufficient amount of

oil can damage it very seriously.The use of a non-detergent or two-

stroke engine oil can reduce the life of the engine.

On a flat surface and with the engine

off, remove the cap with the dipstick

and dry it.Push it fully in without screw-

ing it on, then take it out and check the

oil level. If the level is close to or below

the lower limit (MIN) of the dipstick,

top up with the recommended oil until

the upper limit (MAX) is reached.

Screw the dipstick cap back

on.

Refuel using a funnel. Avoid

overfilling;filler neck has a max

level indication.

The tank's capacity is indi-

cated in chapter 10.

In the event of spilling on the body, quickly remove

petrol traces.

Refuelling should be carried out in an open

or well ventilated area with engine stopped. Always remem-

ber that petrol fumes are inflammable. DO NOT TAKE A

NAKED FLAME TO THE TANK’S OPENING IN ORDER TO SEE

THE TANK’S CONTENTS AND DO NOT SMOKE WHEN REFU-

ELLING.

•

Fuel containing alcohol

If you intend to use fuel with alcohol, ensure that

its octane number is at least as high as that recommended by

Honda (86).There are two types of fuel/alcohol mixtures: one con-

tains ethanol and the other methanol.

IMPORTANT

DANGER!

NOTE

IMPORTANT

IMPORTANT

8

EN

OPERATOR

GR.-CATCHER

BLADES

TRANSMISSION

BRAKE

ENGINE

A) PILOT LAMPS ON

(Key in «ON» position)

Sitting

YES

Disengaged

«N»

Engaged

Stopped

Sitting

NO

Disengaged

«N»

Disengaged

Stopped

B) WHEN STARTING

(Key in «START» position)

Sitting

–/–

Disengaged

1...5 - F / R

Engaged

Does NOT start

Sitting

–/–

Engaged

«N»

Engaged

Does NOT start

Absent

–/–

Disengaged

«N»

Disengaged

Does NOT start

C) WHEN MOVING

(Key in «ON» position)

Sitting

YES

Disengaged

1...5 - F / R

Engaged

Stops

Absent

YES

Disengaged

«N»

Disengaged

Stops

D) WHEN CUTTING GRASS

(Key in «ON» position)

Sitting

NO

Engaged

–/–

Disengaged

Stops

Sitting

YES

Engaged

R

Disengaged

Stops *

Absent

YES

Disengaged

«N»

Disengaged

Stops

Absent

YES

Engaged

–/–

Engaged

Stops

* This may be avoided by keeping the push-button 4.7 pressed