4

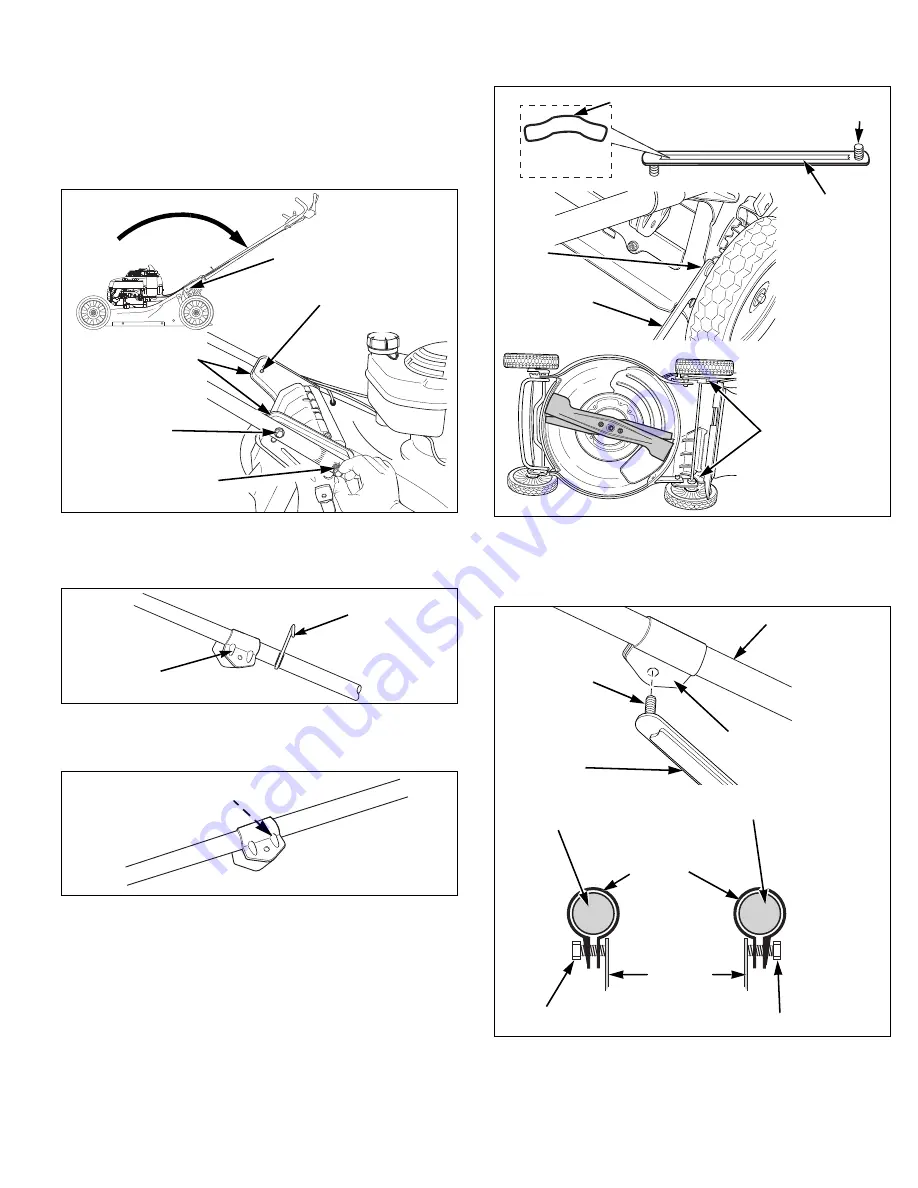

Adjust the Handlebar

1. Align the handlebar’s lower bolt holes with the holes in the handle

stay by rotating the handlebar into the operating position, and then

holding it in place. Loosely install the two 8 x 16 mm flange bolts.

The handlebar height can be adjusted to two different heights. It is

set in the highest position from the factory. To adjust the handlebar

to the lowest position, remove the two 8 x 40 mm flange bolts and

8 mm lock nuts, and then reposition into the lower holes in the

handle stays. Tighten the flange bolts and lock nuts securely.

2. Tighten both lower handlebar flange bolts securely.

3. Pry open the right side handle support hanger, and place it over

the right handle above the starter rope guide. Squeeze the ends

together. Make sure the ribs are facing out, as shown.

4. Pry open the left side handle support hanger, and place it over the

left handle. Squeeze the ends together. Make sure the ribs are

facing out, as shown. Be sure the cables are routed outside the

support hanger, and are not pinched in the hanger.

5. Lower the rear height adjusters to the lowest cutting height position

).

6. Tilt the mower on its right side (muffler side facing the ground).

7. The handle support plates have a curvature to them (rounded on

one side and dished on the other side). The rounded side should

face toward the grass bag.

Insert the lower stud on the end of the handle support plates into

the lower holes in the sides of the mower deck, and then loosely

install an 8 mm self-locking nut on both lower studs from the inside

of the mower deck. Do not fully tighten the nuts at this point.

8. Tip the mower back onto its wheels.

9. From the grass bag side of the handlebar, insert the stud on the

end of each handle support plate through the handle support

hanger. Make sure the stud goes through both holes in the handle

support hanger.

10.Install an 8 mm self-locking nut on each upper stud.

11.Tighten all four self-locking nuts on the handle support plate studs.

8 x 16 mm

FLANGE BOLT (2)

HANDLE STAY

LOWER BOLT

HOLE

8 x 40 mm

FLANGE BOLT (2)

HANDLEBAR

LOWEST POSITION

BOLT HOLE

RIBS

OUT

STARTER ROPE

GUIDE

RIBS OUT

8 mm

SELF-LOCKING

NUT (2)

HANDLE

SUPPORT

PLATE

This side should face the grass bag.

HANDLE

SUPPORT

PLATE

Cross Section

View

LOWER

HOLES

LOWER

STUD

LEFT HANDLEBAR

RIGHT HANDLEBAR

HANDLE SUPPORT

HANGER

HANDLE

SUPPORT

PLATE

8 mm LOCK NUT

LEFT HANDLEBAR

HANDLE

SUPPORT

HANGER

HANDLE

SUPPORT

PLATE

UPPER STUD

8 mm LOCK NUT