MAINTENANCE

HRR216PKA

3-8

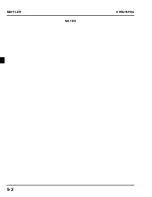

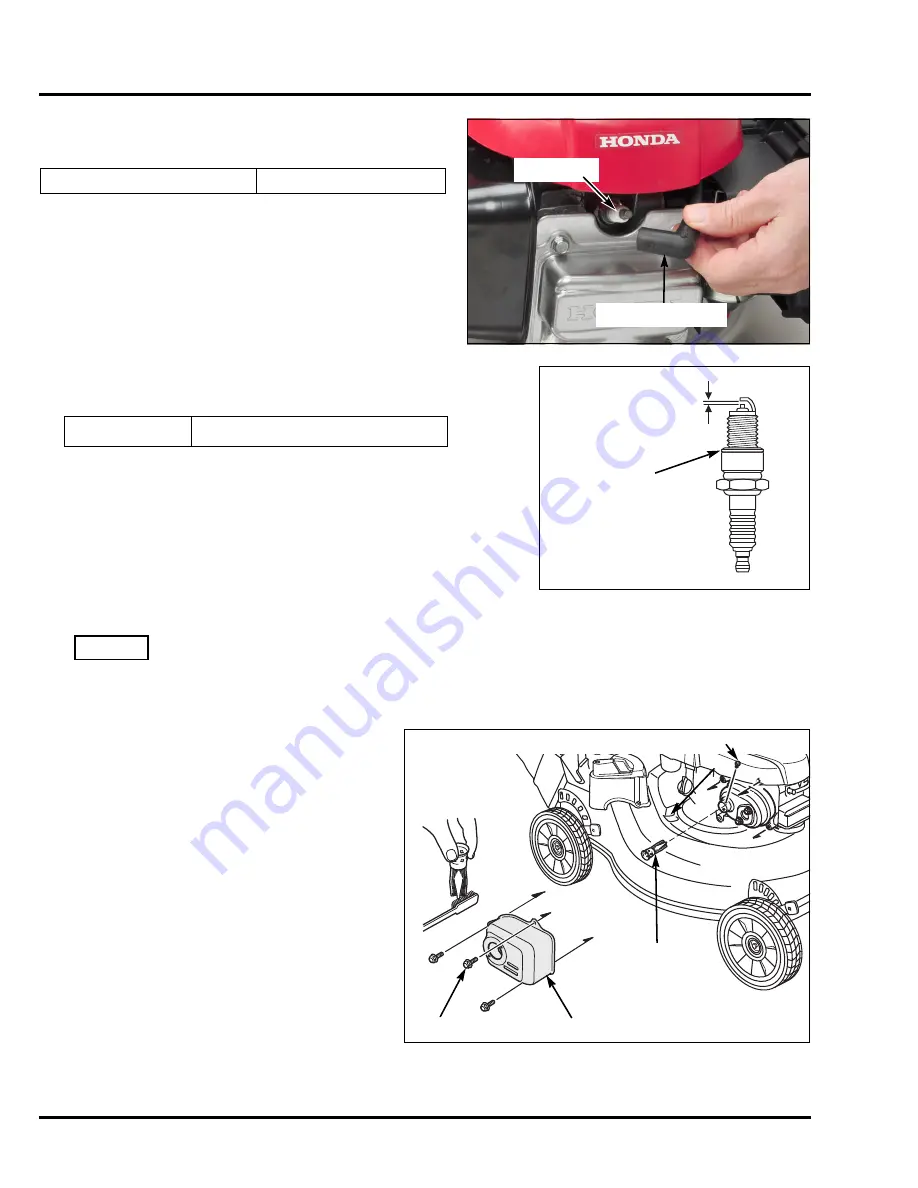

9. SPARK PLUG INSPECTION

Using an incorrect spark plug can cause engine damage. Use

the recommended spark plug or an exact equivalent.

1. Remove the spark plug with a 13/16 in (21 mm) spark plug

wrench.

2. Visually inspect the spark plug. Discard the plug if the

insulator is cracked or chipped.

3. Measure the plug gap with a wire-type gauge. If

necessary, adjust the gap by bending the side electrode.

4. Make sure the sealing washer is in good condition and replace if

necessary.

5. Install the plug finger-tight to seat the washer, then tighten with a plug

wrench to compress the sealing washer:

Tighten a new plug 1/2 turn after the plug seats.

Tighten a reused plug 1/8 ~ 1/4 turn after the plug seats.

TORQUE:

20 N•m (14 ft-lb)

NOTICE

A loose spark plug can overheat and damage the engine. Overtightening can

damage the threads in the cylinder head.

10. SPARK ARRESTER

CLEANING

(OPTIONAL PART)

The spark arrester must be serviced every 100 hours

to keep it functioning as designed.

1. Remove the three flange bolts from the muffler

protector.

2. Remove the 4 x 6 mm self-tapping screw from

the spark arrester, and remove the spark

arrester from the muffler. Be careful not to

damage the spark arrester screen.

3. Check for carbon deposits around the exhaust

port and spark arrester. Clean with a wire brush,

if necessary. Replace the spark arrester if there

are any breaks or tears.

4. Install the spark arrester and muffler protector in the reverse order of disassembly.

Recommended spark plug

NGK BPR5ES

Spark plug gap

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

SPARK PLUG CAP

SPARK PLUG

0.028 ~ 0.031 in

(0.7 ~ 0.8 mm)

SEALING

WASHER

HO

SETSCREW

SPARK ARRESTER

FLANGE BOLT (3)

HEAT SHIELD

Summary of Contents for HRR216PKA

Page 5: ...iv HRR216PKA NOTES...

Page 9: ...SPECIFICATIONS HRR216PKA 1 4 NOTES...

Page 45: ...MUFFLER HRR216PKA 5 2 NOTES...

Page 49: ...RECOIL STARTER HRR216PKA 6 4 NOTES...