HRR216PKA

CAM PULLEY/CRANKSHAFT/PISTON/ CYLINDER BLOCK

9-5

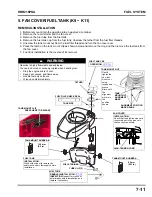

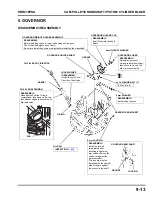

OIL PAN REMOVAL

1. Set piston at TDC of compression stroke.

2. Remove the 6 x 25 mm flange bolts

3. Insert a screwdriver or equivalent tool into the recess as

shown, and remove the oil pan from the cylinder block.

Be careful not to damage the sealing surfaces. Use a tool

that fits tightly into the recesses. Twist the tool to break the

sealant loose. Do not drive the tool into the sealing

surfaces with a hammer.

PISTON ASSEMBLY/CONNECTING ROD CAP

INSTALLATION

1. Apply oil to the inner wall of the cylinder and

to the outer surface of the piston.

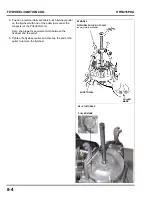

2. Install the piston assembly in the cylinder so that the model

mark (for example: ZL8 or Z8B) by the piston pin hole and

the longer side of the connecting rod big end are at the

right side. (The crankshaft must be at the top dead center

of the compression stroke.)

The model mark on the piston must be positioned toward

the oil pan.

NOTICE

Take care not to break the piston ring when installing the

piston assembly in the cylinder.

3. Apply clean engine oil to the cylinder block crankshaft

bearing area, and install the crankshaft in the cylinder

block.

4. Apply oil to the connecting rod big end bearing and the

crank pin; then connect the connecting rod to the crank pin.

5. Apply oil to the connecting rod cap bearing.

6. Install so that the projection by the oil dipper and the

projection of the connecting rod face in the same direction.

Note that the oil dipper must be on the right- hand side at

this time.

7. Tighten the connecting rod bolts to the specified torque.

TORQUE:

12 N•m (9 ft-lb)

RECESS

MODEL MARK

CONNECTING

ROD WITH THE

LONG END

OIL DIPPER

PROJECTIONS

Summary of Contents for HRR216PKA

Page 5: ...iv HRR216PKA NOTES...

Page 9: ...SPECIFICATIONS HRR216PKA 1 4 NOTES...

Page 45: ...MUFFLER HRR216PKA 5 2 NOTES...

Page 49: ...RECOIL STARTER HRR216PKA 6 4 NOTES...