CAM PULLEY/CRANKSHAFT/PISTON/ CYLINDER BLOCK

HRR216PKA

9-10

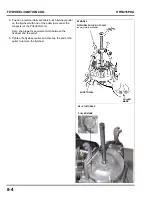

COMBUSTION CHAMBER CLEANING

1. Prepare a cylinder of thick paper or equivalent material,

with a diameter large enough to fit against the inner wall of

the cylinder, and insert it into the cylinder for protection.

2. Attach a combustion chamber cleaning brush

(commercially available) to an electric drill and clean the

combustion chamber.

Be sure to insert thick paper into the cylinder to protect the

inner wall of the cylinder during cleaning of the combustion

chamber.

Do not press the cleaning brush with force against the

combustion chamber.

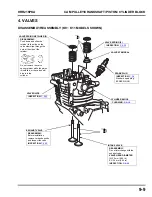

VALVE SEAT RECONDITIONING

Valve Seat Inspection

1. Thoroughly clean the combustion chambers and valve

seats to remove carbon deposits using the procedure

shown above.

2. Apply a light coat of Prussian Blue compound or erasable

felt-tipped marker ink to the valve faces.

3. Insert the valves, and then lift them and snap them closed

against their seats several times. Be sure the valve does

not rotate on the seat.

The transferred marking compound will show any area of

the seat that is not concentric and may require valve seat

reconditioning.

ELECTRIC

DRILL

THICK PAPER OR

EQUIVALENT

VALVE FACE

Summary of Contents for HRR216PKA

Page 5: ...iv HRR216PKA NOTES...

Page 9: ...SPECIFICATIONS HRR216PKA 1 4 NOTES...

Page 45: ...MUFFLER HRR216PKA 5 2 NOTES...

Page 49: ...RECOIL STARTER HRR216PKA 6 4 NOTES...