HRR216PKA

CAM PULLEY/CRANKSHAFT/PISTON/ CYLINDER BLOCK

9-11

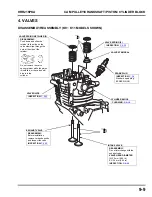

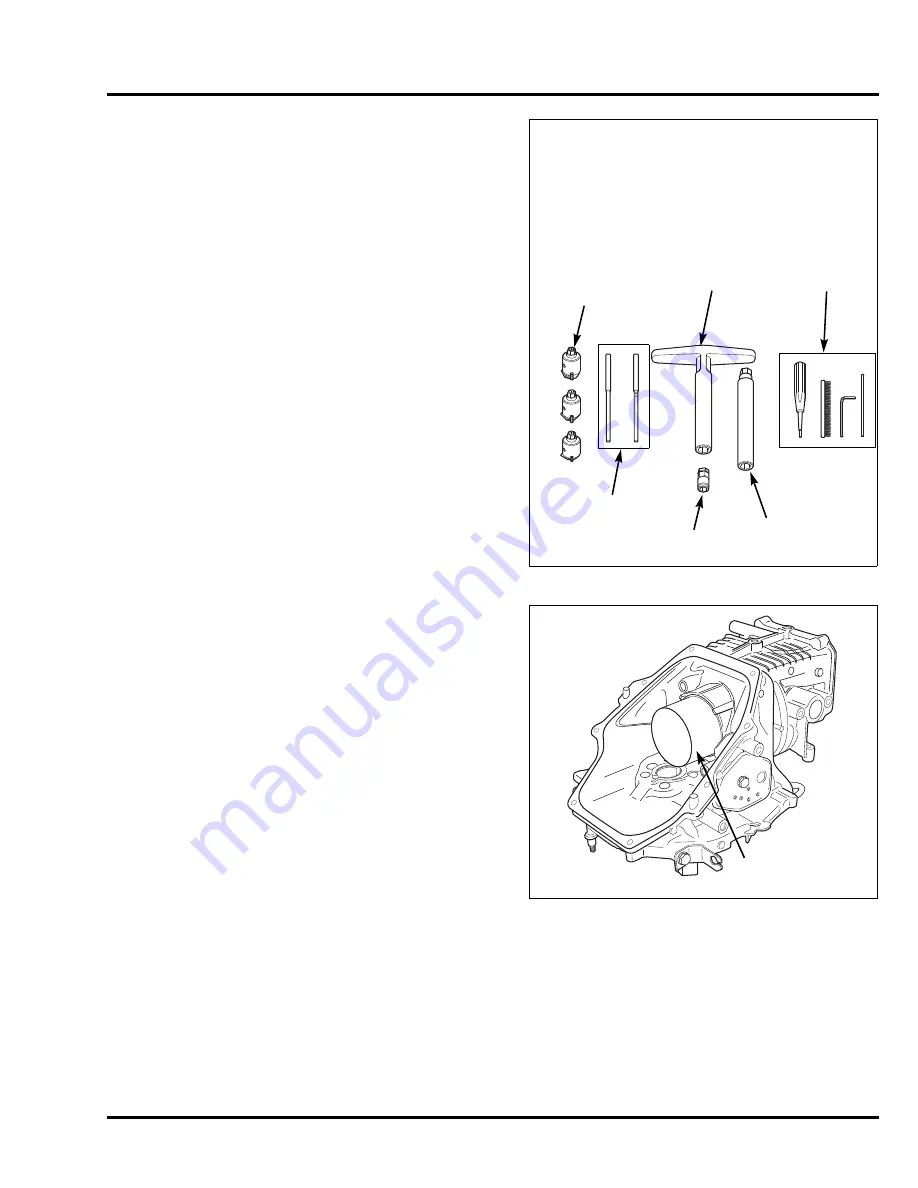

Valve seat reconditioning tools (commercially available)

Reconditioning Procedure

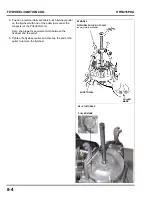

1. Prepare a thick paper cylinder or equivalent material with

a large enough diameter to fit against the cylinder wall of

the cylinder block.

2. Insert the thick paper into the cylinder to protect the

cylinder wall during valve seat reconditioning.

60°

45°

31°

VALVE SEAT

CUTTER

SOLID PILOT BAR, 5.50 mm (NWY PM 100055SH)

SOLID PILOT BAR, 5.51 mm (NWY PM 100552S)

VALVE SEAT CUTTER #115, 31° (NWY CU 115

VALVE SEAT CUTTER #122, 45° (NWY CU 122)

VALVE SEAT CUTTER #111, 60° (NWY CU 111)

T-WRENCH #505 (NWY TW #503-1)

T-WRENCH ADAPTOR (NWY TW 503-1)

ACCESSORY PACKAGE (NWY TW #246)

T-WRENCH

T-WRENCH

ADAPTOR

ACCESSORY

PACKAGE

SOLID PILOT

BARS

T-WRENCH

EXTENSION, 6 in

31°

45°

60°

THICK PAPER OR

EQUIVALENT

Summary of Contents for HRR216PKA

Page 5: ...iv HRR216PKA NOTES...

Page 9: ...SPECIFICATIONS HRR216PKA 1 4 NOTES...

Page 45: ...MUFFLER HRR216PKA 5 2 NOTES...

Page 49: ...RECOIL STARTER HRR216PKA 6 4 NOTES...