HRR216PKA

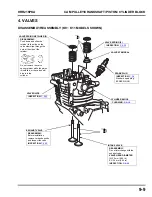

CAM PULLEY/CRANKSHAFT/PISTON/ CYLINDER BLOCK

9-19

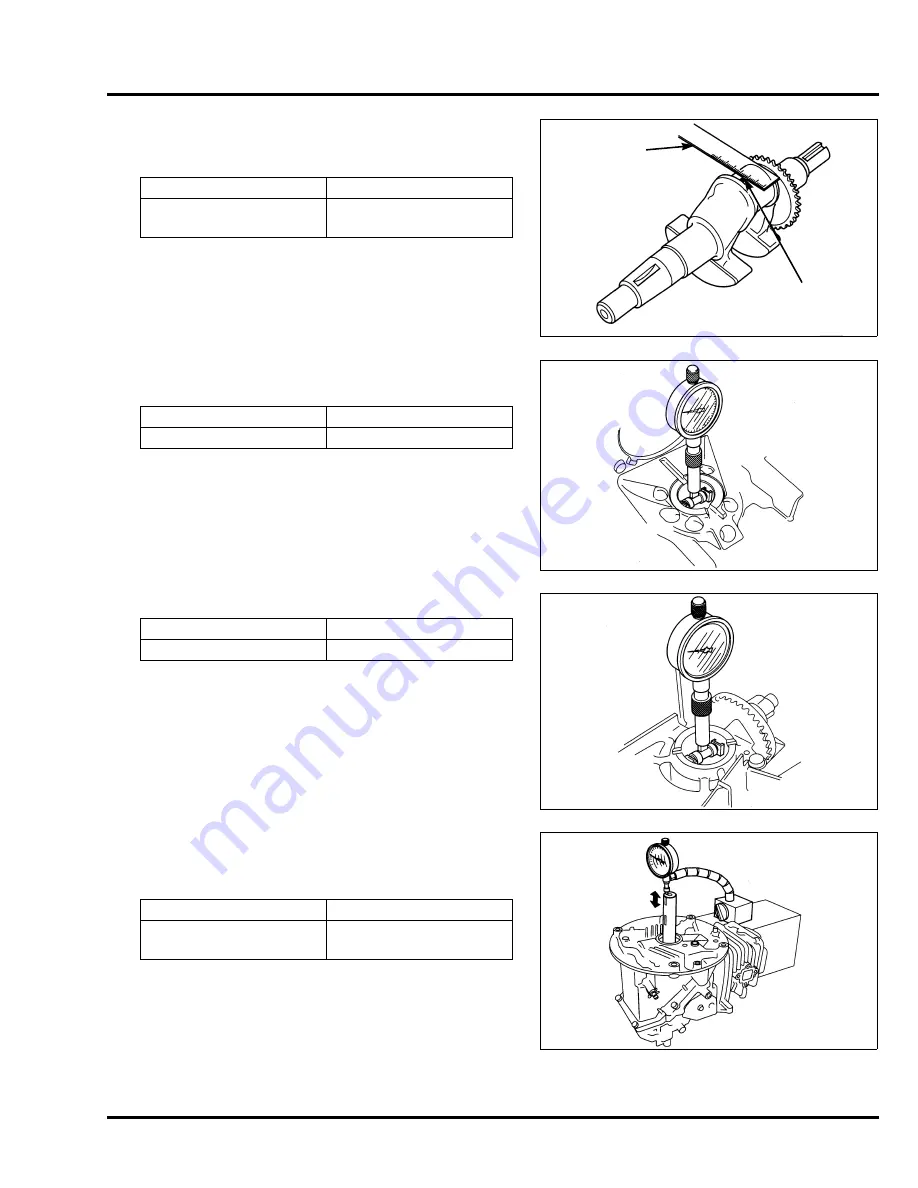

3. Remove the connecting rod cap and measure the

Plastigage

®

with the scale on the Plastigage package to

determine the oil clearance.

4. If the clearance exceeds the service limit, measure the

connecting rod I.D. and crankpin O.D. and replace the

worn parts as necessary. Recheck the big end oil

clearance.

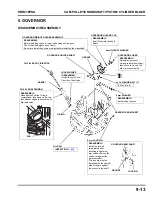

CYLINDER BLOCK MAIN JOURNAL I.D.

INSPECTION

Inspect the bearing surface for scoring or damage. If the bearing

surface is worn or damaged, the cylinder block and

crankshaft will require replacement.

OIL PAN MAIN JOURNAL I.D. INSPECTION

Inspect the bearing surface for scoring or damage. If the bearing

surface is worn or damaged, the oil pan and crankshaft will

require replacement.

CRANKSHAFT AXIAL CLEARANCE INSPECTION

Measure the crankshaft axial play before removing the oil pan,

crankshaft, and piston.

If the axial clearance is too great, inspect the oil pan and timing

gear thrust washer for wear and replace as necessary.

Standard oil clearance

Service limit

0.040 ~ 0.063 mm

(0.0016 ~ 0.0025 in)

0.12 mm

(0.005 in)

Standard

Service limit

25.420 mm (1.0008 in)

25.466 mm (1.0026 in)

Standard

Service limit

28.020 mm (1.1031 in)

28.066 mm (1.1050 in)

Standard

Service limit

0.15 ~ 0.75 mm

(0.006 ~ 0.030 in)

1.0 mm

(0.04 in)

PLASTIGAGE

PLASTIGAGE

SCALE

Summary of Contents for HRR216PKA

Page 5: ...iv HRR216PKA NOTES...

Page 9: ...SPECIFICATIONS HRR216PKA 1 4 NOTES...

Page 45: ...MUFFLER HRR216PKA 5 2 NOTES...

Page 49: ...RECOIL STARTER HRR216PKA 6 4 NOTES...