14

ENGLISH

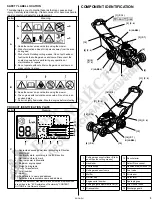

Spark Plug Service

NOTICE

Incorrect spark plugs can cause engine damage.

For good performance, the spark plug [1] must be properly gapped

and free of deposits.

1. Disconnect the spark

plug cap [2], and

remove any dirt from

around the spark

plug area.

2. Remove the spark

plug with a spark

plug wrench [3].

3. Inspect the spark

plug. Replace it if the electrodes

are worn or if the insulator is

cracked or chipped.

4. Measure the spark plug electrode

gap with a suitable gauge. The

gap should be 0.7 ~ 0.8 mm.

Correct the gap, if necessary, by

carefully bending the side

electrode.

5. Install the spark plug carefully, by

hand, to avoid cross-threading.

6. After the spark plug seats, tighten with a spark plug wrench to

compress the washer.

If reinstalling the old spark plug, tighten 1/8 to 1/4 turn after the

spark plug seats.

If installing a new spark plug, tighten 1/2 turn after the spark plug

seats to compress the washer [4].

NOTICE

A loose spark plug can overheat and damage the engine.

Overtightening the spark plug can damage the threads in the

cylinder head.

7. Install the spark plug cap on the spark plug.

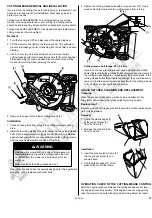

Spark Arrester Service

In Europe and other countries where machinery directive 2006/42/EC

is enforced, this cleaning should be done by your servicing dealer.

The spark arrester must be serviced every 100 hours to keep it

functioning as designed.

1. Allow the engine to cool, and then remove the three bolts [1] from

the muffler shield [2] using a 10 mm socket wrench.

2. Remove the muffler shield [2].

3. Remove the screw [4].

4. Remove the spark arrester [3] from the muffler [5].

5. Check for carbon deposits on the spark arrester and the exhaust

port. Brush carbon deposits away. Be careful to avoid damaging

the spark arrester screen.

6. Install the spark arrester in the muffler.

7. Install the muffler components on the engine, and tighten the three

bolts securely.

Recommended spark plugs:

NGK - BPR5ES

[2]

[1]

[3]

0.7 ~ 0.8 mm

[4]

[5]

[4]

[2]

[3]

[1]