46

SERVICING YOUR SNOWBLOWER

SPARK PLUG SERVICE

Recommended spark plug:

BPR5ES (NGK)

W16EPR-U (DENSO)

Use only the recommended spark plugs or equivalent. Spark plugs

which have an improper heat range may cause engine damage.

To ensure proper engine operation, the spark plug must be properly

gapped and free of deposits. If the engine has been running, the

muffler will be very hot. Be careful not to touch the muffler.

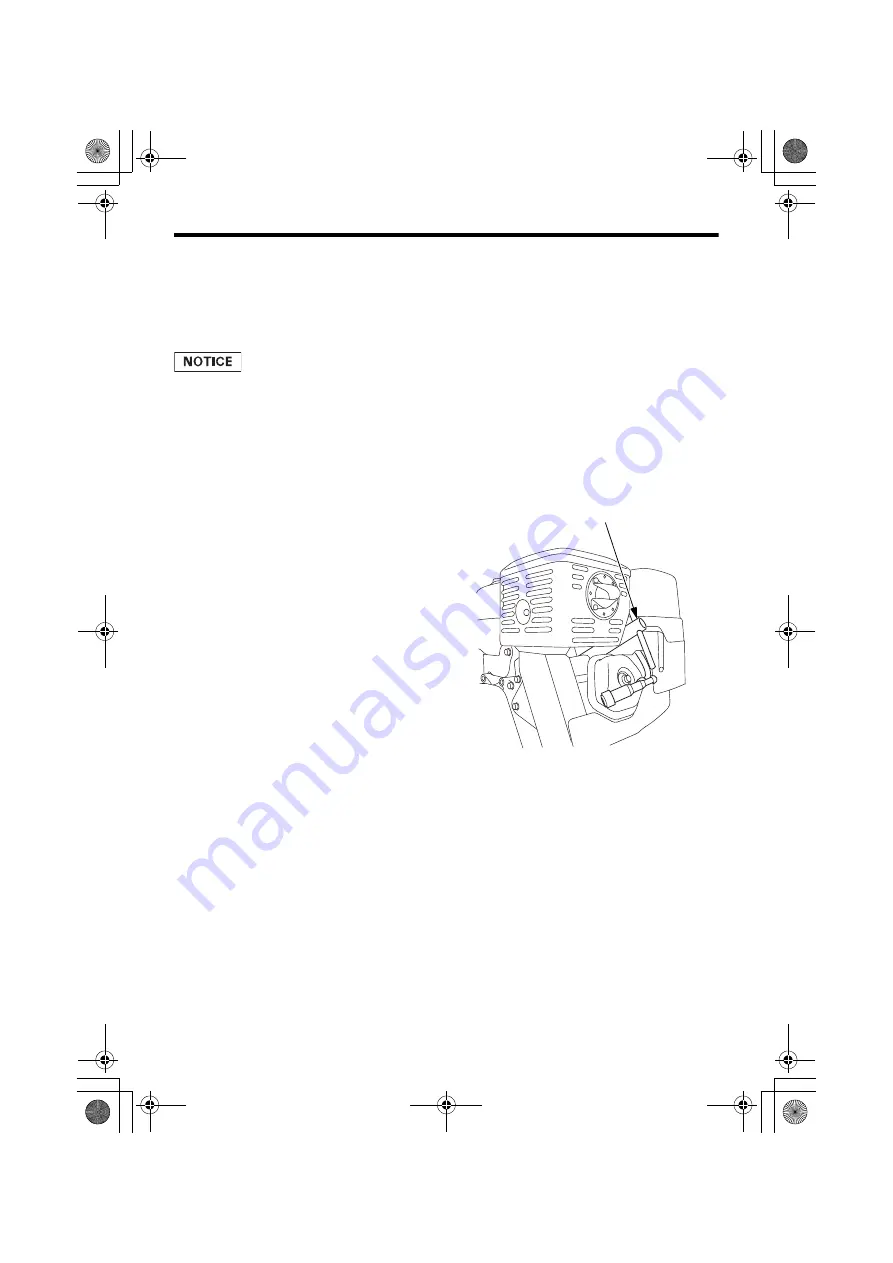

1.Remove the spark plug cap.

2.Clean any dirt from around the

spark plug base.

3.Use the spark plug wrench

supplied in the tool kit to

remove the spark plug.

4.Inspect the spark plug. Replace

it if the electrodes are worn or if

the insulator is cracked,

chipped, or fouled.

SPARK PLUG WRENCH

31V416010.book 46 ページ 2014年5月19日 月曜日 午後2時50分