7 EN

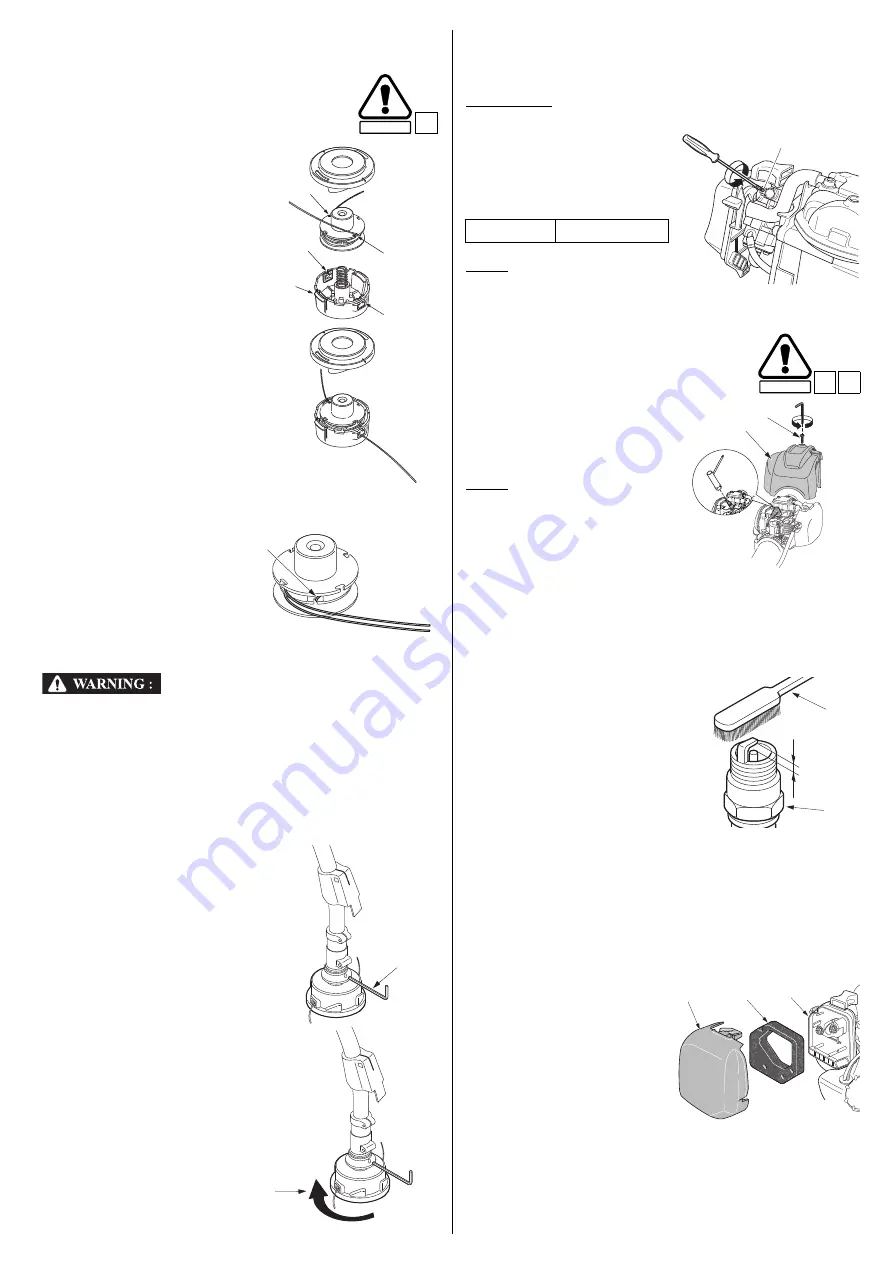

REPLACING THE LINE

1. Press the lugs [1] located on either side of the

head to open it.

2. Extract the reel and remove

the rest of the nylon line.

3. Prepare 3 metres of 2.4 mm

diameter line and fold it in

half, lengthwise.

4. Place the middle of the line

in the notch [2] in the reel

and coil the wire by turning

in the specified direction.

5. Secure the ends in the two

opposite notches [3]

(leaving an excess of 10 cm

of line).

6. Reinstall the reel in its place

and feed the lines through

the two side holes [4].

7. Reinstall the cover.

CAUTION:

• Always use a line of the

diameter recommended in the

technical specifications.

• Poor results would be

obtained if the line diameter is

too large as this will result in

an excessive load on the

engine, so reducing its

performance.

Never replace the nylon line with a line of a different material,

such as steel wire.

To avoid severe personal injury, disconnect the spark plug cap

to prevent accidental starting.

Wear heavy gloves to protect your hands when replacing the

nylon head.

DISASSEMBLING THE

NYLON LINE CUTTING

HEAD

1. Hold the cutting head firmly

using the hexagonal

wrench [5] supplied.

2. Unscrew the nylon line

cutting head (by turning in

the clockwise direction) [6].

3. To reassemble the nylon line

cutting head, proceed in the

reverse order of

disassembly.

ADJUSTING THE CARBURETTOR

PROCEDURE

Start the engine and let it warm up

to normal operating temperature.

Then turn the idle screw [7] to the

right or left to obtain the correct

setting.

NOTE:

If any adjustment is

required, please use the table

opposite.

CHECKING THE SPARK PLUG

1. To reach the spark plug, the

top cover must be removed

from the engine [8].

Use the hexagonal wrench

supplied to undo the bolt [9].

NOTE:

Hot parts and moving

parts (flywheel) are exposed

when the engine top cover is

removed. Never use your grass

trimmer with the engine cover

removed.

2. Remove the cap and unscrew

the spark plug using the wrench supplied.

3. Clean the electrodes with a wire brush [10] to remove carbon

deposits.

4. If the electrodes show signs of wear, replace the spark plug [11]

with a new one with the same characteristics.

5. Check the spark plug gap with

feeler gauges. When adjustment

is required, carefully bend the

side electrode.

6. Reinstall the spark plug and

screw it finger-tight onto its seat.

7. For new spark plugs, tighten by

an additional 1/2 turn with the

spark plug wrench.

When the same spark plus is

installed, 1/8 to 1/4 of a turn is enough.

CAUTION:

• If a spark plug is insufficiently tightened, it is liable to heat up and

damage the engine. If the spark plug is overtightened or cross-

threaded, irreparable damage could be caused to the engine

block.

AIR CLEANER MAINTENANCE

The foam air filter element must

be cleaned regularly to prevent

impurities from entering the

engine and causing premature

wear. A dirty air filter will reduce

engine power and increase fuel

consumption.

1. Open the air filter cover [12]

and remove the filter [13] from

the filter housing [14].

2. Clean the filter with warm soapy water or in a nonflammable

solvent and then leave to dry.

3. Dip the element in clean engine oil and squeeze out the excess

oil.

4. Reinstall the foam filter element and the filter cover.

SAFETY

C11

[4]

[3]

[1]

[3]

[4]

[2]

[5]

[6]

Idle speed

3 100 rpm

[7]

C1

SAFETY

B7

[8]

[9]

0,6-0,7 mm

[10]

[11]

[12]

[13]

[14]

Summary of Contents for UMS425E1

Page 64: ...RCS ORL ANS B 501 736 565...