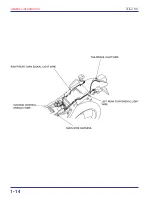

FILLER CAP/DIPSTICK

LOWER LEVEL

FILLER CAP/DIPSTICK

OIL FILTER SCREEN CAP

FILTER SCREEN

SPRING

ENGINE OIL LEVEL CHECK

t

Start the engine and let it idle for 2-3 minutes.

Turn off the engine and support the motorcycle in an upright

position on level ground.

Remove the filler cap/dipstick, wipe it clean, but do not screw it.

Remove the filler cap/dipstick and check the oil level.

• If the engine must the running to do some work, make sure

the area is well ventilated. Never run the engine in an

enclosed area. The exhaust contains poisonous carbon

monoxide gas that may cause loss of consciousness and

lead to death.

XL2 0 0

2-3

If the oil level is below the lower mark on the dipstick, fill to the

upper level mark with the recommended oil.

ENGINE OIL CHANGE/OIL FILTER SCREEN

t

NOTE

Remove the oil filter screen cap.

Operate the starter motor 2-3 seconds to completely drain any

residual oil.

Clean the oil filter screen.

• Drain the oil while the engine is warm and the motorcycle is

on its side stand.

• The oil filter screen and spring will come out when the oil

filter screen plug is removed.

• Use box wrench or 24 mm socket to prevent rounding the

corners on the screen plug.

• If the engine must be running to do some work, make sure

the area is well ventilated. Never run the engine in an

enclosed area. The exhaust contains poisonous carbon

monoxide gas that may cause loss of consciousness and

lead to death.

• Used engine oil may cause skin cancer if repeatedly left in

contact with the skin for prolonged periods. Although this is

unlikely unless you handle used oil on a daily basis, it is still

advisable to thoroughly wash your hands with soap and

water as soon as possible after handling used oil.

LUBRICATION

Summary of Contents for XL200 2001

Page 1: ...SH O PMANU AL XL200 MOTO HONDA DA AMAZÔNIA LTDA 2001 1 ...

Page 15: ...XL2 0 0 GENERAL INFORMATION 1 11 ...

Page 16: ...XL2 0 0 1 12 GENERAL INFORMATION ...

Page 17: ...XL2 0 0 GENERAL INFORMATION 1 13 ...

Page 18: ...XL2 0 0 1 14 GENERAL INFORMATION ...

Page 19: ...XL2 0 0 GENERAL INFORMATION 1 15 NOTES ...

Page 22: ...XL2 0 0 LUBRICATION 2 0 CRANKSHAFT OIL FILTER ROTOR OIL PUMP COUNTERSHAFT MAIN SHAFT CAMSHAFT ...

Page 29: ...XL2 0 0 2 8 LUBRICATION NOTES ...

Page 48: ...XL2 0 0 FUEL SYSTEM 4 0 ...

Page 64: ...XL2 0 0 FUEL SYSTEM 4 17 NOTES ...

Page 67: ...5 0 XL2 0 0 ENGINE REMOVAL INSTALLATION ...

Page 92: ...XL2 0 0 CYLINDER HEAD VALVES 6 19 NOTAS ...

Page 95: ...XL2 0 0 CYLINDER PISTON 7 0 ...

Page 101: ...XL2 0 0 CYLINDER PISTON 7 7 NOTAS ...

Page 116: ...XL2 0 0 CLUTCH GEARSHIFT LINKAGE 8 13 NOTES ...

Page 119: ...XL2 0 0 ALTERNATOR STARTER CLUTCH 9 0 75 Nm 7 5 kg m 53 ft lb 5 Nm 0 5 kg m 4 ft lb ...

Page 129: ...XL2 0 0 ALTERNATOR STARTER CLUTCH 9 11 NOTAS ...

Page 132: ...XL2 0 0 CRANKSHAFT TRANSMISSION 10 0 12 N m 1 2 kg m 9ft lb ...

Page 144: ...XL2 0 0 CRANKSHAFT TRANSMISSION 10 13 NOTAS ...

Page 169: ...XL2 0 0 FRONT WHEEL SUSPENSION STEERING 11 23 NOTAS ...

Page 172: ...XL2 0 0 REAR WHEEL SUSPENSION 12 0 ...

Page 190: ...XL2 0 0 REAR WHEEL SUSPENSION 12 19 NOTAS ...

Page 226: ...XL2 0 0 IGNITION SYSTEM 16 7 NOTES ...

Page 237: ...XL2 0 0 ELECTRIC STARTER 17 9 NOTES ...

Page 240: ...XL2 0 0 LIGHTS METERS SWITCHES 18 0 ...

Page 248: ...XL2 0 0 LIGHTS METERS SWITCHES 18 9 NOTES ...

Page 250: ...XL2 0 0 19 WIRING DIAGRAM 19 1 19 ...

Page 257: ...MOTO HONDA DA AMAZÔNIA LTDA ...