GB

6

MU0H-1155GE23 R0319

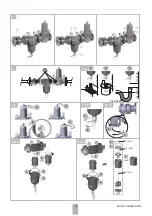

8.3 Cleaning

8.3.1 Sieve

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Unscrew filter bowl

5.

Remove filter insert

6.

Clean sieve

7.

Re-insert the filter insert

8.

Screw filter bowl in place

9.

Slowly open shut-off valve on inlet

10. Slowly open shut-off valve on outlet

9

Disposal

See Chapter 4 Scope of Delivery

Observe the local requirements regarding correct

waste recycling/disposal!

10 Troubleshooting

Problem

Cause

Remedy

Beating sounds

Pressure reducing valve is too

large

Call Technical Customer Service

Water is escaping from the spring bonnet Diaphragm is faulty

Replace diaphragm

Spring bonnet not screwed flush

Retighten the screws

O-ring forgotten in the diaphragm piston

during assembly

Insert O-ring

Too little or no water pressure

Shut-off valves up- or downstream of the

pressure reducing valve are not fully

open

Open the shut-off valves fully

Filter mesh dirty

Reverse rinsing

Pressure reducing valve is not set to the

desired outlet pressure

Set outlet pressure

Water station not mounted in the

direction of flow

Fit water station in flow direction (note

direction of arrow on housings)

Increased differential pressure between

inlet and outlet pressure gauge

Reverse rinsing interval is exceeded

Reverse rinsing

High degree of dirt in the water

Reverse rinsing

Decrease reverse rinsing interval

Replace filter sieve