GB-18

D

GB

F

NL

I

E

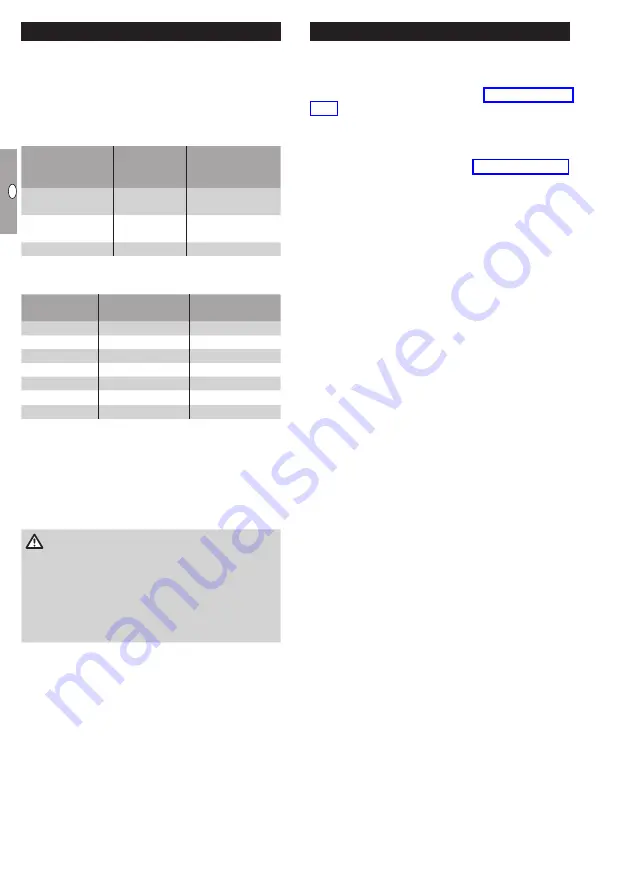

Technical data

Heating: direct with eductor or indirect in radiant tube.

Control type: On/Off.

Adjusting range: 60% to 100%.

Flame velocity: approx. 130 to 170 m/s.

Flame control: direct ionization control (UV control

as an option).

Ignition: direct spark ignition.

Burner

Recuperator

Max. flue gas

temperature at

recuperator inlet

ECOMAX

®

..C

Ceramic

(SiSiC)

1250°C*

ECOMAX

®

..M/

ECOMAX

®

..P

Cast steel

1150°C

ECOMAX

®

..F

Metallic

1050°C

*

We advise against using this in forging and heat-

ing furnaces in which raw material is heated.

Burner

Capacity [kW]

Flame length

[mm]*

ECOMAX

®

0

25

300

ECOMAX

®

1

36

300

ECOMAX

®

2

60

400

ECOMAX

®

3

100

450

ECOMAX

®

4

180

800

ECOMAX

®

5

250

800

ECOMAX

®

6

500

1000

* Visible range for natural gas operation in the

open air, max. connection rating and air in-

dex 1.15.

If the burners are used at geodetic altitudes of over

500 m above MSL, the possible capacity will be

lower as a result of the reduced density of gas and air.

Guide value: 5% per 1000 m above MSL.

WARNING

Information pursuant to REACH Regulation No.

1907/2006, Article 33.

Insulation contains refractory ceramic fibres (RCF)/

aluminium silicate wool (ASW).

RCF/ASW are listed in the Candidate List of the

European REACH Regulation No. 1907/2006.

▷

Information on the safe handling of products

containing ceramic fibres can be found in the

safety data sheets.

▷

Safety data sheets are available on request.

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page 2 (Part designa-

tions). Transport the product in dry, clean conditions.

Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page 18 (Technical data).

Storage time: 2 years before using for the first time. If

stored for longer than this, the overall service life will

be reduced by the corresponding amount of extra

storage time.

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.