VR9205R SERIES 1000 DIRECT IGNITION GAS CONTROL WITH INTEGRATED GAS/AIR MODULE

3

69-2305—03

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be a

problem, provide covers for the control to limit

contamination.

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control. If the

appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary, to

protect the control. Proper insulation or shielding should

be provided by the appliance manufacturer; verify proper

air circulation is maintained when the appliance is

installed.

INSTALLATION

When Installing this Product…

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2.

Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

Follow these warnings exactly:

1. Disconnect power supply before wiring to

prevent electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas,

turn off gas supply at the appliance service

valve before starting installation, and perform

Gas Leak Test after installation is complete.

3. Always install a sediment trap in gas supply line

to prevent contamination of gas control.

4. Do not force the on-off switch. Use only your

fingers to operate the on-off switch. Never use

any tools. If the electronic on-off switch does

not operate by hand, the gas control should be

replaced by a qualified service technician.

Force or attempted repair may result in fire or

explosion.

5. Plan the installation as outlined below.

6. Plan for frequent maintenance as described in

the maintenance section.

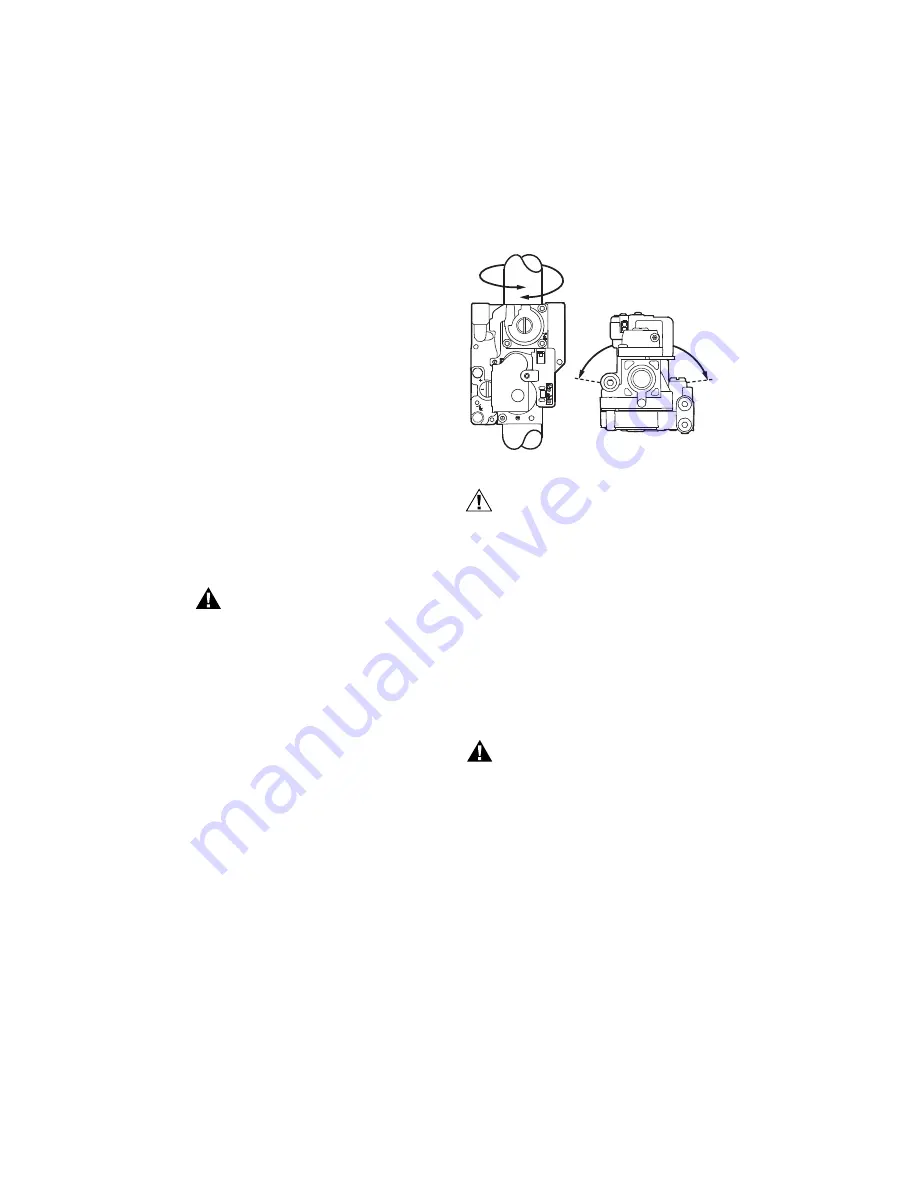

Mounting position

The valve can be mounted 0 to 90 degrees in any

direction from the top of the valve facing up, including

outlet facing upward or downward. See Fig. 2. If the valve

is mounted horizontally; the top of the valve must be even

with or above the center line of the piping.

NOTE: A deviation of more than 3° from the OEM's orig-

inal design mounting orientation can result in an

unacceptable change in gas outlet pressure.

See OEM application installation guide.

To prevent blockage due to condensation, the positive air

pressure connection should not be connected to

combustion products.

Fig. 2. VR9205R Series 1000 mounting.

CAUTION

Equipment Damage Hazard.

Can burn out thermostat or transformer.

Applying a jumper across (or shorting) the valve

coil terminals, even temporarily, can burn out the

thermostat or transformer.

Follow the appliance manufacturers instructions if

available; otherwise use these instructions as a guide.

IMPORTANT

These gas controls are shipped with protective

seals over the inlet and outlet tappings. Do not

remove the seals until ready to install adapters

or connect the piping.

Converting Gas Control from Natural Gas

to LP Gas (or LP Gas to Natural Gas)

WARNING

Fire Or Explosion Hazard.

Can cause property damage, severe injury

or death.

VR9205R cannot be converted between LP or

Natural gas. To convert, see appliance

manufacturer for recommendations.

Install Bushings To Control

If bushings are being installed on the control, mount them

as follows:

Bushings

1.

Remove the seal over the control inlet or outlet.

2.

Apply a moderate amount of good quality pipe

compound to the bushing, leaving two end threads

bare. On an LP installation, use compound that is

resistant to LP gas. Do not use Teflon tape.

3.

Insert the bushing in the control and carefully thread

the pipe into the bushing until tight.

M29133

VERTICAL

PIPING

HORIZONTIAL

PIPING

INLET OR

OUTLET

0 TO 90°

0 TO 90°

TOP OF VALVE