4-45

CHAPTER 4 - INSTAllATION INSTRUCTIONS

MAN0448_Issue 13_01-2010

5704 Control System

005704-M-5001 A03249

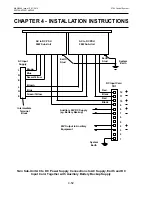

Non-isolated Analogue Output Connection with Power from

System 57 Using Source Module

Quad Relay Interface Card

05704-A-0121

Four Channel Control Card Fitted with:

Analogue Output Module (Sink) 04200-A-0145

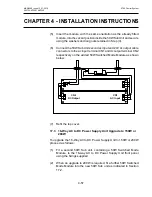

Non-isolated Analogue Output Connection with Power from

System 57 Using Sink Module

Current

Sense

Analogue 24V

Quad Relay Interface Card

05704-A-0121

Four Channel Control Card Fitted with:

Analogue Output Module (Source) 04200-A-0146

27

29

28

Analogue Channel 1

Analogue 0V

+24V

(18V to 40V)

0V

Current

Sense

29

28

Analogue Channel 1

Analogue 0V

+24V

(18V to 40V)

0V

27

Anlogue 24V

Summary of Contents for 5704

Page 1: ...System 57 5704 Control System Operating Instructions ...

Page 4: ...4 MAN0448_Issue 13_01 2010 5704 Control System 005704 M 5001 A03249 ...

Page 6: ...6 MAN0448_Issue 13_01 2010 5704 Control System 005704 M 5001 A03249 User Notes ...

Page 14: ...1 8 MAN0448_Issue 13_01 2010 5704 Control System 005704 M 5001 A03249 User Notes ...