- 2 -

Contents

1. General ....................................................................................................... 3

1.1 Introduction to Actuator ...................................................................................................... 3

1.2 Actuator Structure ................................................................................................................ 3

2. Storage ....................................................................................................... 4

3. Operation ................................................................................................... 5

3.1 Inspections before Operation ............................................................................................. 5

4. Maintenance and Repair ........................................................................... 6

4.1 Valve Disassembly ............................................................................................................... 6

4.2 Disassembly and Assembly of Actuator ............................................................................ 7

4.2.1 Disassembly (See Fig 4.1) ................................................................................................7

4.2.2 Assembly (See Fig 4.1) ....................................................................................................7

5. Preventive Maintenance and Troubleshooting ....................................... 9

5.1 Troubleshooting ................................................................................................................... 9

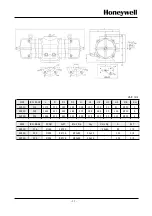

6. Dimension Table ...................................................................................... 10

6.1 Double Acting Type ............................................................................................................ 10

6.2 Spring Return Acting Type ................................................................................................ 12