Maintenance

7/99

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

10-11

10.7 Resetting All Configuration and Calibration Values to Factory

Settings

Introduction

A “cold reset” function is available to return ALL configuration values to the factory settings

shown in Table 5-1. During a cold reset the cal factor will be changed to match the cell constant.

The calibration trim or TDS conversion factor will be removed. All alarms will be cleared and

outputs will go to zero. Some I/O setup values will also be returned to the factory defaults.

This “cold reset” contrasts with the “warm reset” that occurs following loss of power and at the

end of system setup (see Section 5). During a warm reset, alarms are not cleared, and outputs are

maintained at their last value prior to the loss of power or initiation of the cold reset. A warm

reset has no effect on configuration or calibration values.

Procedure

To do a cold reset, returning all configuration and calibration values to their factory settings,

follow the procedure in Table 10-6.

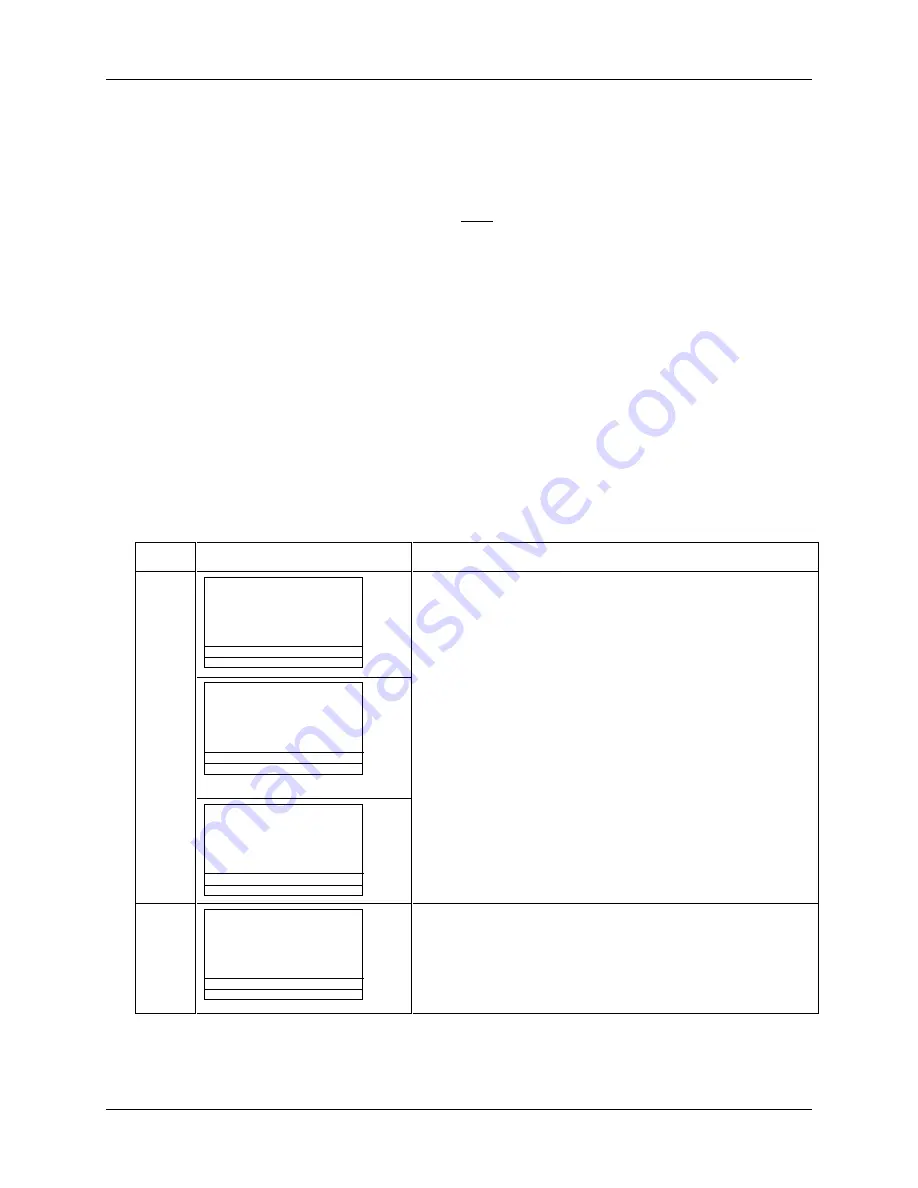

Table 10-6 Procedure for Resetting All Configuration to Factory Settings

Step

Screen

Action

1

MENU

CONFIGURATION

CALIBRATION

MAINTENANCE

I/O SETUP

DIAGNOSTICS

| PREV | NEXT

Go to MAINTENANCE | INSTRUMENT SETUP | RESET

UNIT.

MAINTENANCE

OFFLINE FUNCTIONS

INSTRUMENT SETUP

LEAD RESISTANCE COMP

DIAGNOSTICS

| PREV | NEXT

INSTRUMENT SETUP

INSTURMENT TAGGING

PRODUCT INFO

SCREEN CONTRAST

SECURITY

RESET UNIT

DIAGNOSTICS

| |

2

UNIT RESET

ATTENTION

ALL PARAMETERS

WILL BE RESET TO

FACTORY DEFAULTS!

DIAGNOSTICS

RESET| |

Pressing the specified function key at this point will

perform a cold reset as described above.

As the reset is completed. the display will go blank, then

for a few seconds product information will be displayed.

Finally, the display will return to showing process values.