L7224U OIL ELECTRONIC AQUASTAT

®

CONTROLLER

69-1720—03

8

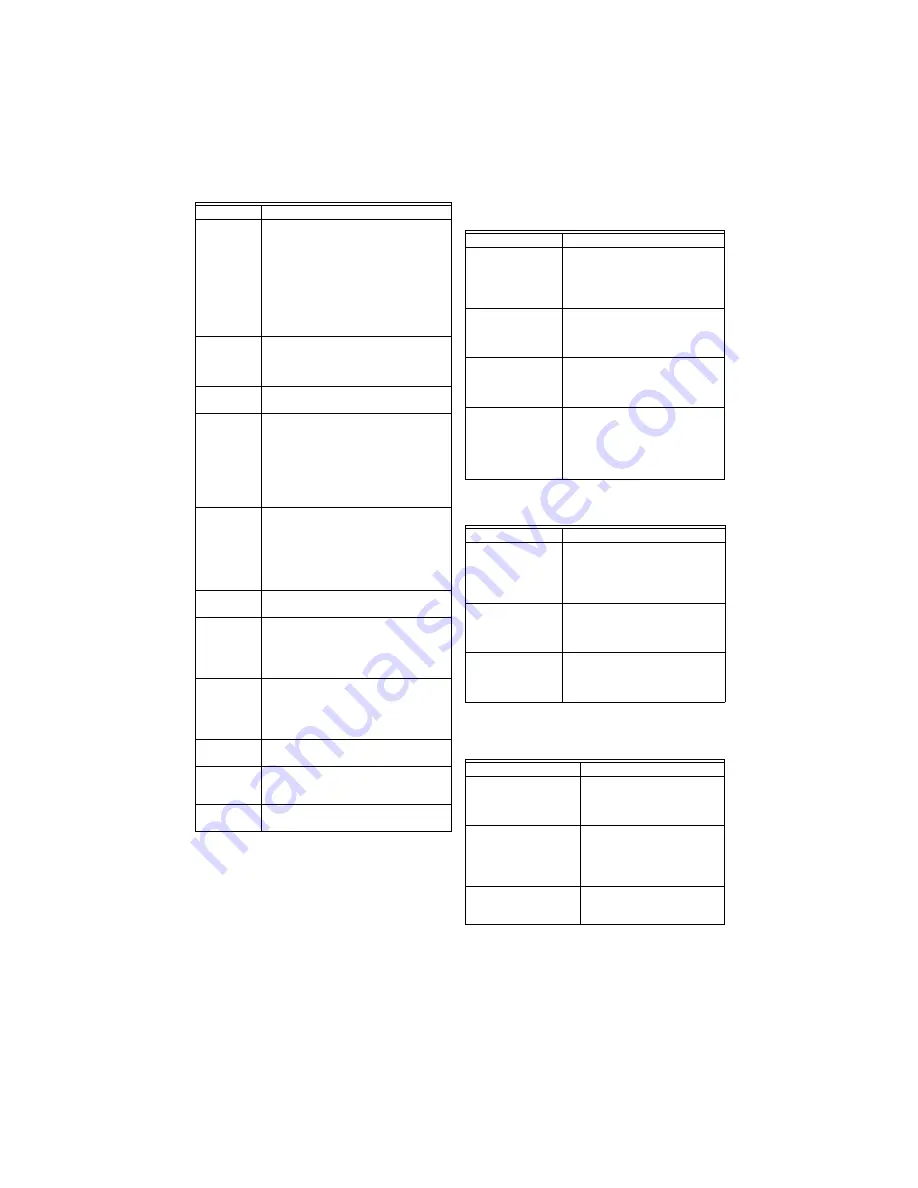

Table 3. L7224/L7248 Controller Operating Sequence.

* Error condition only available when the Outdoor Reset

Module is installed.

Action

System Response

Thermostat

calls for heat.

Circulator starts when water temperature is

above Low Limit setting (if applicable).

Boiler temperature is checked. Burner

starts when water temperature is below

High Limit setting.

If Anti-short Cycle Time is enabled, the

burner does not start until the set Anti-

short Cycle Time between cycles expires

after the previous call for heat was

satisfied.

Boiler

temperature

exceeds the

High Limit.

Burner is turned off. Burner restarts when

the water temperature drops below the

High Limit setting minus the Differential.

Thermostat is

satisfied.

Circulator and burner turn off.

Boiler

temperature

drops below

the Low Limit

setting minus

the

differential (if

applicable).

Burner is turned on, Circulator is turned

off. Burner stops when the water

temperature exceeds the Low Limit

setting.

Error

conditions

1-5.

If an error condition is detected, all outputs

except ZC are shut down. Burner is off.

The controller continues to function and

restarts when error is corrected.

During the error check sequence, the

system checks for drift in the sensor and

corrosion in the connections.

Error

condition 6.

EnviraCOM communication is not

available.

Error

condition 7.

The controller has reset the High Limit,

Low Limit and Differential Setting to a

default setting and will continue to run at

those settings. Performance of the system

will be degraded.

Error

condition 8.

If the error condition is detected, all

outputs except ZC are shut down. Burner

is off.The controller continues to function

and restarts when all three user keys have

been pressed longer than 60 seconds.

Error

condition 9*.

System continues to run with no outdoor

reset functionality

Error

condition 10*.

System continues to run with outdoor reset

parameters enabled as programmed.

Error cleared automatically.

Error

condition 11*.

System continues to run with boiler temp

set to High Limit.

Table 4. L7224 Controller Operating Sequence with

multiple zones connected through the ZR terminal

Action

System Response

Zone Request (ZR)

terminal is

connected to L1

(Zone calls for

heat).

Boiler temperature is checked.

Burner starts when water

temperature is below High Limit

setting. Anti Short-Cycle Time is

applied, see Table 3.

Boiler temperature

exceeds the High

Limit.

Burner is turned off. Burner restarts

when the water temperature drops

below the High Limit setting minus

the Differential.

Zone Request input

is de-energized

(Zones are

satisfied).

Burner turns off.

Boiler temperature

drops below the

Low Limit setting

minus the

differential (if

applicable).

Burner turns on and Zone Control

is de-energized. Burner turns off

and Zone Control is re-energized

when the water temperature

exceeds the Low Limit setting.

Table 5. Controller Operating Sequence with External

Low Limit device connected trough the ZR terminal.

Action

System Response

Zone Request (ZR)

terminal is

connected to L1

(External Low Limit

call for heat).

Boiler temperature is checked.

Burner starts when water

temperature is below High Limit

setting. Circulator turns off.

Boiler temperature

exceeds the High

Limit.

Burner is turned off. Burner restarts

when the water temperature drops

below the High Limit setting minus

the Differential.

Zone Request input

is de-energized

(External Low Limit

is satisfied).

Burner is turned off.

Table 6. L7224 Controller Operating Sequence with

Domestic Hot Water connected trough the ZR

terminal.

Action

System Response

Zone Request (ZR)

terminal is connected to

L1 (Domestic Hot Water

calls for heat).

Boiler temperature is checked.

Burner starts when water

temperature is below High

Limit setting.

Boiler temperature

exceeds the High Limit.

Burner is turned off. Burner

restarts when the water

temperature drops below the

High Limit setting minus the

Differential.

Zone Request input is

de-energized (Domestic

Hot Water is satisfied).

Burner is turned off.