L8100A,B,C Aquastat

®

CONTROLLERS

60-2336—3

3

Available Options:

External adjustment screw and visible control point scale.

Factory set stop at 140

°

F (60

°

C).

Approvals:

Underwriters Laboratories Inc. Component Recognized:

File No. MP466, Guide Number MBPR2.

American Gas Association Design Certified: Report

Number 23-11B.

Part Available:

110641 Jumper to convert four-terminal L8100 to three-

terminal L8100.

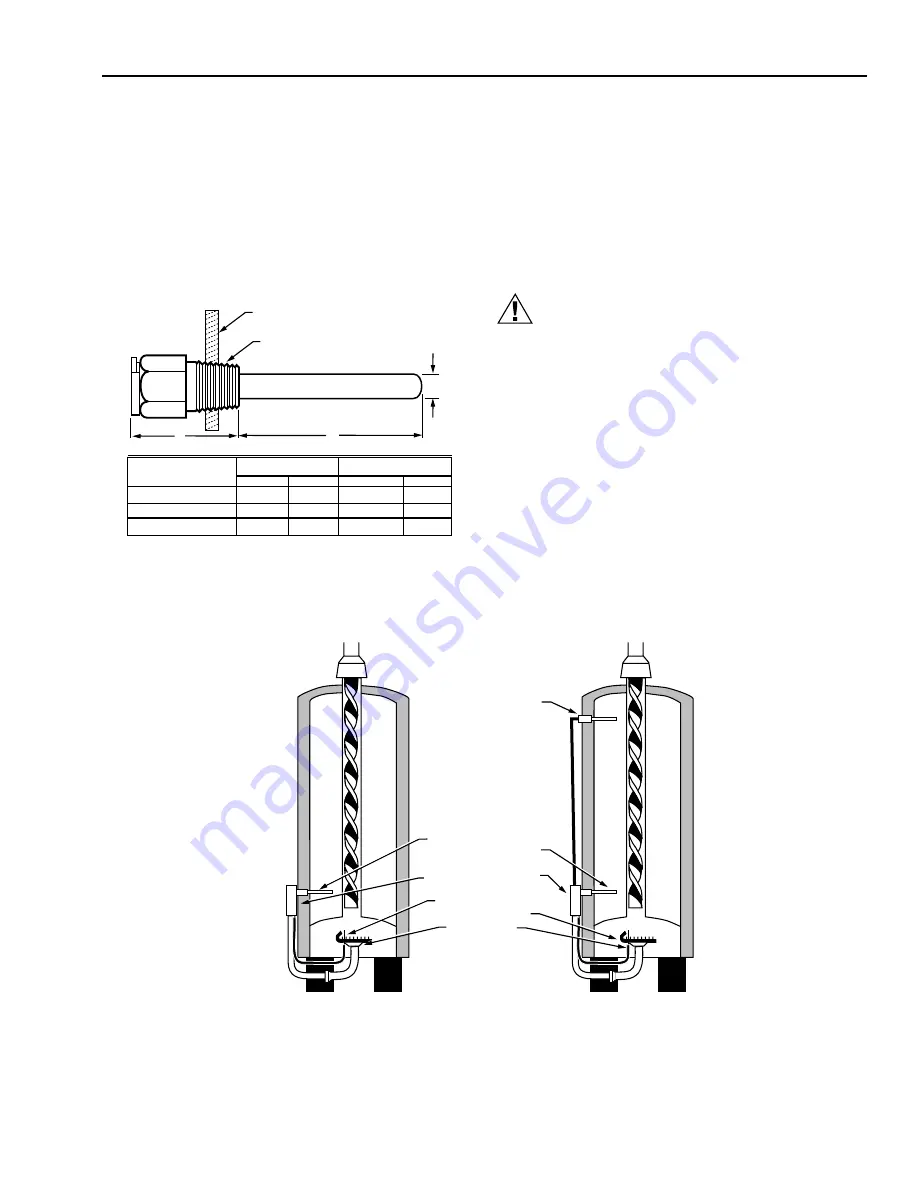

1/2 OR 3/4 — 14 NPT

C

B

A

M4746

CONTROLLER WELL

REMOTE WELL

A INSULATION DEPTH

B INSERTION DEPTH

C WELL DIAMETER

IN.

MM

2-1/4

5

7/16

57

127

11

1-1/2 OR 2-1/2

3

7/16

38 OR 64

76

11

TANK WALL

IN.

MM

Fig. 2. Approximate dimensions for the controller

immersion well and remote immersion well in in. (mm).

INSTALLATION

When Installing this Product...

쐃

Read instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

쐇

Check ratings and descriptions given in the

specifications to make sure the product is suitable for

your application.

쐋

Installer must be a trained, experienced service

technician.

쐏

After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect power before installation to prevent

electrical shock or equipment damage.

Mounting Direct Immersion Well

The manufacturer usually provides a tapping for insertion of

the controller sensing element. This tapping is located at a

point where typical water temperature can be measured.

Follow the instructions furnished by the system manufacturer,

if available, or use the procedure below. See Fig. 3.

UPPER

SENSING BULB

SENSING BULB AND

ECO SWITCH LOCATION

L8100A

L8100B,C

THERMOCOUPLE

AND PILOT BURNER

MAIN BURNER

M4759

Fig. 3. Location of L8100A,B,C Aquastat® Controllers.