EAGLE CONTROLLER – INSTALLATION & COMMISSIONING INSTRUCTIONS

EN1Z-0970GE51 R1112

10

WIRING AND SET-UP

General Safety Considerations

When connecting the EAGLE, both VDE, National Electric

Code (NEC) or equivalent, and any local regulations must

be observed.

Electrical work should be carried out by a qualified

electrician.

Electrical connections must be made at terminal blocks.

For Europe only: To comply with CE requirements, devices

with a voltage in the range of 50 ... 1000 VAC or 75 ...

1500 VDC which are not provided with a supply cord and

plug or with other means for disconnection from the supply

having a contact separation of at least 3 mm in all poles

must have the means for disconnection incorporated in the

fixed wiring.

WARNING

Risk of electric shock or equipment damage!

►

Do not touch any live parts in the cabinet.

►

Disconnect the power supply before making connections to

or removing connections from terminals of the EAGLE

Controller and devices wired to it.

►

Do not use spare terminals as wiring support points.

►

Do not reconnect the power supply until you have

completed the installation.

►

Mixing of different voltages (e.g., 24 V and 230 V) within

individual relay blocks of the EAGLE is not allowed

►

To prevent a risk of injury due to electrical shock and/or

damage to the device due to short-circuiting, low-voltage

and high-voltage lines must be kept separate from one

another.

►

All terminals are protected (up to 24 Vac) against short-

circuiting and incorrect wiring (except when the 3-position

slide switch is set to “END,” in which case the terminals of

the RS485-1 bus [24, 25, and 26] have no such

protection). Higher voltages may damage the device.

►

Do not open the controller housing.

►

Observe precautions for handling electrostatic sensitive

devices.

NOTE:

All wiring must comply with applicable electrical

codes and ordinances. Refer to job or manu-

facturer’s drawings for details. Local wiring guide-

lines (e.g., IEC 364-6-61 or VDE 0100) may take

precedence over recommendations provided in

these instructions.

Fusing Specifications

System Fusing

We recommend that the user equip the system with an

external fuse.

Fusing of Active Field Devices

F2 (depends upon loads in use).

Wiring Terminals

The EAGLE is equipped with push-in terminal plugs.

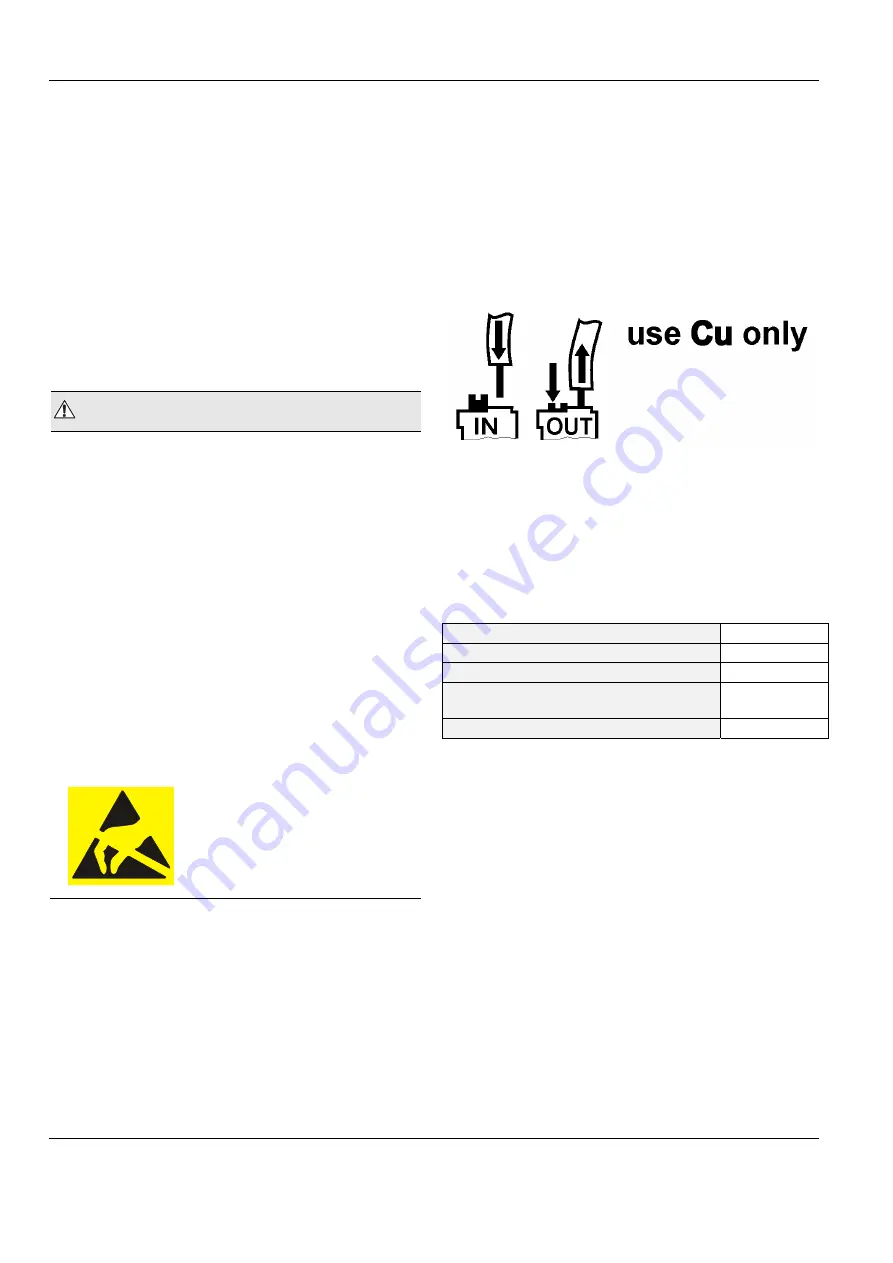

Fig. 17. Inserting/removing wires from push-in terminals

NOTE:

In the case of solid conductors, the use of ferrules is

prohibited.

NOTE:

Use only one conductor per push-in terminal.

NOTE:

If two stranded wires are to be connected to a single

push-in terminal, twin wire end ferrules must be

used.

Table 7. EAGLE push-in terminal wiring specifications

plug gauge

0.2 … 1.50 mm

2

solid conductor H05(07) V-K

0.2 … 1.50 mm

2

stranded conductor H05(07) V-K

0.2 … 1.50 mm

2

stranded conductor with wire end

ferrules (w/o plastic collar)

0.2 … 1.50 mm

2

stripping length

10.0 +1.0 mm

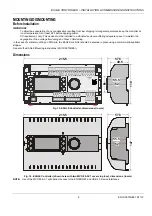

Power Supply

Powering EAGLE

Power is supplied via a removable terminal plug (attached to

terminals 1 and 2). See also Fig. 19.

The power supply of the EAGLE Controller must conform to

Safety Class II.

NOTE:

To reduce overall current consumption, the EAGLE

can also be powered by a switch power supply

(rather than by a transformer). See also Table 2 on

pg. 3.