HAWK 8000 CONTROLLER – INSTALLATION & COMMISSIONING INSTRUCTIONS

EN1Z-1016GE51 R0218

10

during which time the LED will flash in the "Working Mode"

pattern. When the backup completes, the LED will become

dark, and the USB drive can then be removed.

Boot to recover or restore image:

The unit is powered up

while holding down the BACKUP button, for either:

▪ (No USB media detected): A "factory defaults" recovery

from an onboard partition with the default image.

▪ (If USB media is detected): For the restoration of a backup

image on the USB flash drive. NOTE that this also

requires a serial shell connection to the controller's Debug

port.

In either case, the BACKUP LED will start flashing in the

"Alert Mode" pattern. If you then release the BACKUP button

during this period (within 5 seconds), initiation begins for

either:

▪ If no USB media is detected, the "factory defaults"

recovery image installation.

▪ If USB media is detected, the system enters the "restore

mode." In this mode, after log-in with serial shell, a menu

will list the available backup images on the USB flash

drive. You can select one (and enter the unique security

key to initiate its installation), or alternately select to install

the "factory defaults" recovery image.

During a recovery or restore image installation, the LED

flashes in the "working mode" pattern. When the image

installation completes, the BACKUP LED turns OFF. A

controller reboot is then required.

See also the HAWK 8000 Backup and Restore Guide (EN2Z-

1027GE51) for complete details.

CAUTION

Do not remove power while a recovery image install or

backup restore is in progress, i.e., when the BACKUP

LED is flashing in the "working mode" pattern (1 sec

ON / 1 sec OFF, or slow flash). Otherwise, the con-

troller will be inoperable ("bricked"), and must be

returned to a service center for repair.

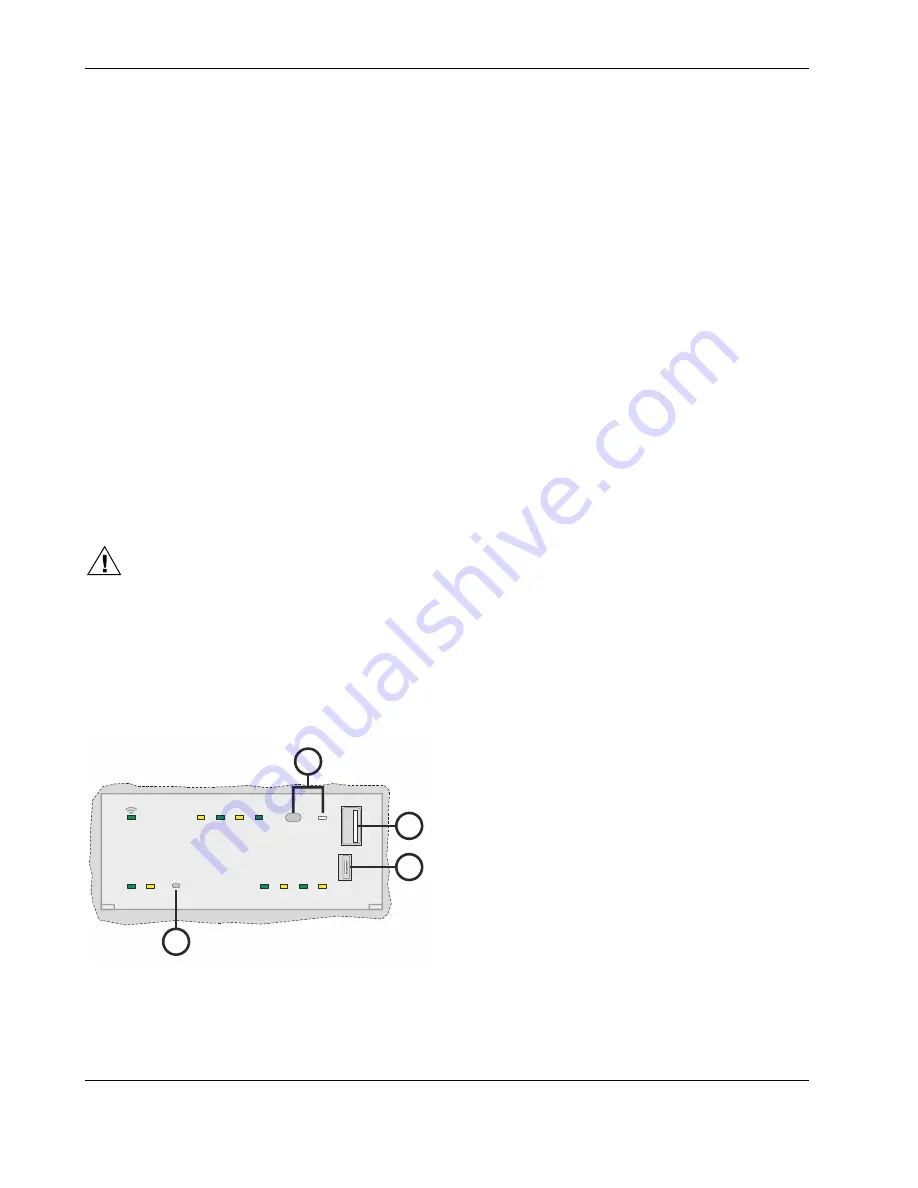

USB Ports and Pushbuttons

Behind the controller's front access door, there are two USB

ports, two pushbuttons, and an associated LED.

BACKUP

SEC

STAT BEAT SHT/DWN

PRI

DEBUG

COM-1

A-RS485-B

COM-2

1

2

3

4

Fig. 15. HAWK 8000 Controller USB ports and

pushbuttons (shown here with access door opened)

Legend

1.

BACKUP button and corresponding BACKUP LED.

2.

PROG: USB 2.0 for use with USB flash (thumb) drive.

3.

DEBUG: Micro-A USB for serial debugging

communications.

4.

SHT/DWN: Recessed pushbutton for initiating a

controlled shutdown.

The DEBUG port is a standard Micro-A type USB port for

serial debugging communications to the controller. You can

use a serial terminal program (for example: PuTTY) to access

the controller's "system shell" menu. This provides access to

a few basic platform settings.

Default DEBUG port settings are: 115200, 8, N, 1 (baud rate,

data bits, parity, stop bits). For more details, see the HAWK

8000 – Installation & Startup Guide (EN1Z-1027GE51).

NOTE:

Logging in will require admin-level platform

credentials.

The SHT/DWN pushbutton initiates a "controlled shutdown" of

the controller, ensuring that all station data is preserved. This

provides an alternative to the platform "stop station"

command, while connected online with the controller.

Initiating a Controller Shutdown

When locally servicing an installed and configured

(commissioned) unit, use this feature before removing power.

NOTE:

Do not initiate a shutdown or remove power if:

The BACKUP LED is flashing in the "working mode"

pattern or

The BEAT LED is flashing at a 90% / 10% ON/OFF

rate.

Instead, wait for the BACKUP LED to change to a

different state (typically: OFF), and for the BEAT

LED to flash at the normal 50% / 50% ON/OFF duty

cycle rate before initiating a shutdown.

Prerequisite:

The HAWK 8000 controller must have been

commissioned (Niagara 4 installed, platform configured, a

station installed) and the unit must be running the station.

1.

Press and hold down the recessed SHT/DWN button

just until the BACKUP LED begins flashing in the "alert

mode" pattern: 100 ms ON / 100 ms OFF, repeating

(fast).

2.

Release the SHT/DWN button during this alert mode.

This starts the shutdown process, where the station and

the software are put into a safe state. During this

shutdown, the BACKUP LED flashes in the "working

mode."

3.

When the shutdown has been completed, the BACKUP

LED will turn OFF. You can now safely remove 24V

power from the unit.

NOTE:

In cases where the system cannot be put into a safe

state, the BACKUP LED will flash in the "error mode"

pattern: two quick (200 ms) flashes ON, 3 seconds

OFF, repeating.