LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

EN0Z-0959GE51

R0615

15

visual indication of the BACnet MS/TP communication status.

When the controller receives power, the LED appears in one

of the following allowable states, as described in Table 7.

Table 7. BACnet status LED states

BACnet LED status

status or condition

solid ON

Controller has power, loader is not

running.

solid ON, blinking OFF

once in 2.5 sec

Controller is in reflash mode, no

MS/TP communication.

solid ON, blinking OFF

twice in 2.5 sec

Controller is in reflash mode, MS/TP

communication present.

solid ON, blinking OFF

three times in 2.5 sec

Controller is in reflash mode, MS/TP

communication data transfer in

progress.

solid OFF, there is no

power

No power to CPU, LED damaged, low

voltage to board, or loader damaged.

solid OFF, blinking ON

once in 2.5 sec

Controller is running, no MS/TP com-

munication.

solid OFF, blinking ON

twice in 2.5 sec

Controller is running, MS/TP com-

munication present.

solid OFF, blinking ON

three times in 2.5 sec

Controller is running, MS/TP com-

munication data transfer in progress

Step 3. Checkout Completion

At this point the controller is installed and powered. To

complete the checkout, the N

IAGARA

F

RAMEWORK

® application

(run on a PC) is used to configure the I/O and functions of the

controller. Refer to the Programming Tool User Guide, form

no. 63-2662, for controller configuration and programming

details.

CONTROLLER REPLACEMENT

There are no serviceable or repairable parts inside the

controller.

WARNING

Fire, Explosion, or Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to modify the physical or electrical

characteristics of this device in any way. If trouble-

shooting indicates a malfunction, replace the

controller.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

To prevent electrical shock or equipment damage,

disconnect power supply before beginning controller

replacement.

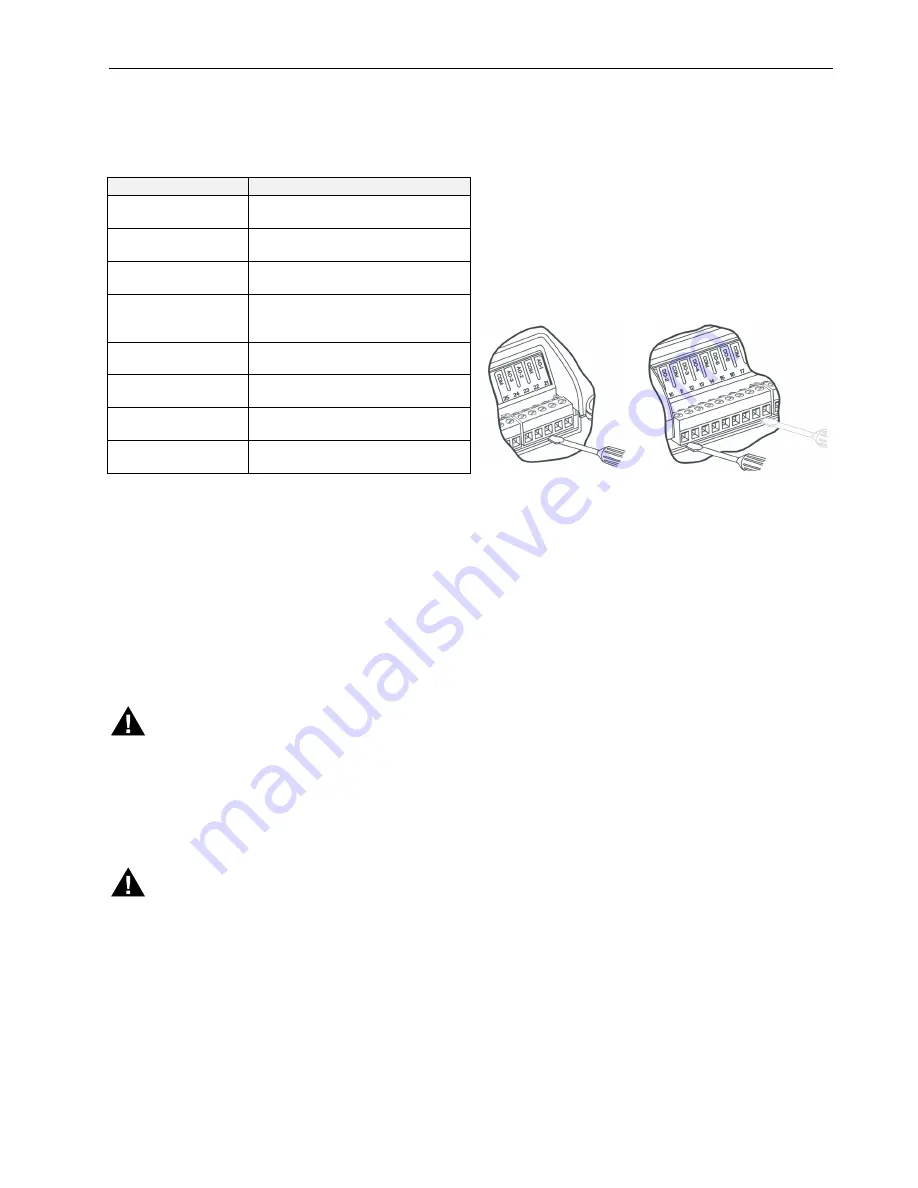

Terminal Block Removal

To simplify controller replacement, all terminal blocks are

designed to be removed with the wiring connections intact

and then re-installed on the new controller. See Fig. 21 and

refer to the following procedure:

IMPORTANT

To prevent bending or breaking the alignment pins on

longer terminal blocks, insert the screwdriver at

several points to evenly and gradually lift up the

terminal block. To prevent damage to the terminal

block alignment pins on the controller circuit board,

insert the screwdriver blade no more than 3 mm.

SHORT TERMINAL

BLOCK

LONG TERMINAL

BLOCK

Fig. 21. Removing terminal blocks

1. Use a thin-bladed screwdriver to evenly raise the terminal

block from its alignment pins:

a. For short terminal blocks (1 to 5 terminals), insert

screwdriver blade in the center of the terminal block

and use a back-and-forth twisting motion to gently

raise the terminal block from its alignment pins.

b. For long terminal blocks (6 or more terminals), insert

screwdriver blade on one side of the terminal block

and gently rotate the blade ¼ turn. Then, move to the

other side of the terminal block and do the same.

Repeat until the terminal block is evenly raised from its

alignment pins.

2. Once the terminal block is raised from its alignment pins,

grasp the terminal block at its center (for long terminal

blocks grasp it at each end) and pull it straight up.