LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

CentraLine

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 845

Fax

+49 (0) 7031 637 740

info@centraline.com

www.centraline.com

Subject to change without notice

EN0Z-0959GE51 R0615

Controller Replacement (AS-models)

For AS-models (which are hard-wired to an actuator), perform

the following actions to replace the complete assembly

(controller and actuator):

1) Remove all power from the controller.

2) Remove the two air flow pickup connections from the

pressure sensor.

3) Remove the terminal blocks (see section “Terminal Block

Removal”).

4) Remove the old controller and actuator assembly from its

mounting.

a) Loosen the two bolts on the actuator clamp to

release the actuator from the shaft.

b) Remove the controller’s mounting screws.

c) Gently pull the controller and actuator assembly

straight out, until the assembly is clear of the

actuator shaft.

5) Mount the new controller and actuator assembly (see

section “Installation” on page 2).

6) Reconnect the two air flow pickup tubes to the pressure

sensor (see section “Piping (AS- and NS-models)” on

page 5).

7) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

8) Restore power to the controller.

9) Perform procedure described in section “Checkout” on

page 14.

Controller Replacement (NS-models)

To replace NS-models, proceed as follows:

1) Remove all power from the controller.

2) Remove the two air flow pickup connections from the

pressure sensor.

3) Remove the terminal blocks (see section “Terminal Block

Removal”).

4) Remove the old controller from its mounting.

IMPORTANT

(IN THE CASE OF CONTROLLERS MOUNTED TO A DIN

RAIL):

1) Push straight up from the bottom to release the top

pins.

2) Rotate the top of the controller outwards to release the

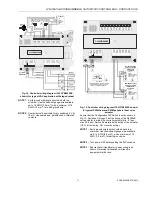

bottom flex connectors (see Fig. 7).

5) Mount the new controller (see section “Installation” on

page 2).

6) Reconnect the two air flow pickup tubes to the pressure

sensor (see section “Piping (AS- and NS-models)” on

page 5).

7) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

8) Restore power to the controller.

9) Perform procedure described in section “Checkout” on

page 14.

Controller Replacement (S-models)

To replace S-models, proceed as follows:

1) Remove all power from the controller.

2) Remove the terminal blocks (see section “Terminal Block

Removal”).

3) Remove the old controller from its mounting.

IMPORTANT

(IN THE CASE OF CONTROLLERS MOUNTED TO A DIN

RAIL):

1) Push straight up from the bottom to release the top

pins.

2) Rotate the top of the controller outwards to release

the bottom flex connectors (see Fig. 7).

4) Mount the new controller (see section “Installation” on

page 2).

5) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

6) Restore power to the controller.

7) Perform procedure described in section “Checkout” on

page 14.

BACnet® is a registered trademark of ASHRAE.

BTL® is a registered trademark of the BACnet International.

N

IAGARA

F

RAMEWORK

® and the Niagara framework logo are

registered trademarks of Tridium, Inc.