LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

EN0Z-0959GE51 R0615

6

NOTE 1:

If controllers are mounted in unusually dusty or

dirty environments, an inline, 5-micron disposable

air filter (use 5-micron filters compatible with

pneumatic controls) is recommended for the high-

pressure line (marked as +) connected to the air

flow pickup.

NOTE 2:

The tubing from the air flow pickup to the controller

should not exceed 1 m. Any length greater than

this will degrade the flow sensing accuracy.

NOTE 3:

Use caution when removing tubing from a con-

nector. Always pull straight away from the con-

nector or use diagonal cutters to cut the edge of

the tubing attached to the connector. Never

remove by pulling at an angle.

1 2 3 4 5 6 7 8 9 0 1

2 2 2 2 2 2 2 2 2 2 3

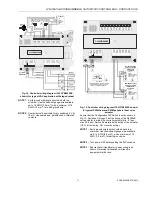

NS- and AS-models

P

AIR FLOW

PICK-UP

RESTRICTOR

PORTS

Fig. 8. Air flow pick-up connections

Power

Before wiring the controller, determine the input and output

device requirements for each controller used in the system.

Select input and output devices compatible with the controller

and the application. Consider the operating range, wiring

requirements, and the environment conditions when selecting

input/output devices. When selecting actuators for modulating

applications, consider using floating control. In direct digital

control applications, floating actuators will generally provide

control action equal to or better than an analog input actuator

for lower cost.

Determine the location of controllers, sensors, actuators, and

other input/output devices and create wiring diagrams. See

Fig. 14 through Fig. 20 for typical controller wiring con-

figurations.

The application engineer must review the control job require-

ments. This includes the sequences of operation for the con-

troller, and for the system as a whole. Usually, there are

variables that must be passed between the controller and

other controllers that are required for optimum system wide

operation. Typical examples include the outdoor air tem-

perature, the demand limit control signal, and the smoke

control mode signal.

It is important to understand these interrelationships early in

the job engineering process, to ensure proper implementation

when configuring the controllers. See the controller

Application Guides.

Power Budget

A power budget must be calculated for each device to deter-

mine the required transformer size for proper operation. A

power budget is simply the sum of the max. power draw

ratings (in VA) of all the devices to be controlled. This

includes the controller itself and any devices powered from

the controller, such as equipment actuators and various

contactors and transducers.

IMPORTANT

When multiple controllers operate from a single

transformer, connect the same side of the transformer

secondary to the same power input terminal in each

device. The earth ground terminal (terminal 3) must be

connected to a verified earth ground for each controller

in the group (see Fig. 10).

Half-wave devices and full-wave devices must not use

the same AC transformer. If a LYNX controller is to

share its power supply with another device, make sure

the other device utilizes a half-wave rectifier and that

the polarity of the wiring is maintained.

Wiring

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

Controller wiring is terminated to the screw terminal blocks

located on the top and the bottom of the device.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

To prevent electrical shock or equipment damage,

disconnect power supply before beginning wiring or

making wiring connections.

NOTE 1:

For multiple controllers operating from a single

transformer, the same side of the transformer

secondary must be connected to the same power

input terminal in each controller. Controller con-

figurations will not necessarily be limited to three

devices, but the total power draw, including

accessories, cannot exceed 100 VA when powered

by the same transformer (U.S., only). For power

and wiring recommendations, See section “Power”

on page 6. The earth ground terminal (terminal 3)

must be connected to a verified earth ground for

each controller in the group (see Fig. 10).

NOTE 2:

All loads on the controller must be powered by the

same transformer powering the controller itself. A

controller can use separate transformers for con-

troller power and output power.