LYNX LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

EN0Z-0957GE51 R0615

10

Table 4. Description of wiring terminals (CLLYUL1012S,

CLLYUL4024S, CLLYVL0000AS, CLLYVL4022AS, and

CLLYVL4024NS)

TERMINAL

LABEL

CONNECTION

CLLYUL4024S,

CLLYVL4024NS

CLLYVL4022AS

a

CLLYUL1012S

CLLYVL0000AS

a

1

1

1

1

24 VAC 24 VAC power

2 2 2 2

24 VAC

COM

24 VAC power

3 3 3 3 EGND

earth

ground

4 4 4 4 20VDC

20

VDC

5 5 5 5 SBUS1

Sylk

6 6 6 6 SBUS2

Sylk

7 7 7 7 NET-1

LonWorks

COM

8 8 8 8 NET-2

LonWorks

COM

9 NA

NA

NA

DO-3

digital

output

b

10 NA NA NA COM

common

b

11 NA NA NA DO-4

digital

output

b

12 NA NA NA COM

common

b

13 13 13 NA DO-1

digital

output

b

14 14 14 NA DO-2

digital

output

b

15 15 15 NA COM

common

b

16 16 16 NA AO-1

analog

output

c

17 17 17 NA COM

common

c

18 18 NA NA AO-2

analog

output

c

19 19 19 NA UI-1

univ.

input

d

20 20 20 NA COM

common

21 21 NA NA UI-2

univ.

input

22 22 NA NA UI-3

univ.

input

23 23 NA NA COM

common

24 24 NA NA UI-4

univ.

input

a

In the case of the CLLYVL0000AS, CLLYVL4022AS controllers, only,

terminals 9 and 11 (DO-3 and DO-4) are internally hardwired to the

actuator.

b

Digital outputs: Open circuit = FALSE, closed circuit = TRUE

c

Analog outputs may be configured as digital outputs and operate as

follows: FALSE (0%) -> 0 Vdc (0 mA), TRUE (100%) -> the max.

11 Vdc (22 mA)

d

UI-1* is a hybrid input. It can be configured either as a DI (fast digital

pulse meter) or as a UI.

IMPORTANT

If the controller is not connected to a good earth

ground, the controller's internal transient protection

circuitry is compromised and the function of protecting

the controller against noise and power line spikes

cannot be fulfilled. This could result in a damaged

circuit board and require replacement of the controller.

Refer to installation diagrams for specific wiring.

All controllers have terminal arrangements similar to the

examples shown in Fig. 13 and Fig. 14 as described in Table

3 and Table 4.

N

EURON

® Service Pin

When pressed, the N

EURON

® Service Pin pushbutton trans-

mits the Service Message to the network, regardless of the

controller's current operating mode (see Fig. 13 and Fig. 14).

CAUTION

Electrical Damage Hazard.

Can cause controller damage or failure.

Do not use any metal object to press the N

EURON

®

Service Pin. Use, instead, a plastic rod or wooden

implement (such as a pencil with the lead broken off)

to press the pin. Using a metal object can damage the

controller's circuitry.

LonWorks Bus Convenience Jack

The L

ON

W

ORKS

® Bus connection is provided by plugging the

Serial L

ON

T

ALK

® Adapter (SLTA) connector into the

L

ON

W

ORKS

® Bus Jack (see Fig. 13 and Fig. 14).

1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0

2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 3 3 3 4

1 2 3 4 5 6 7 8

1

1 1 1 1 1 1 1 1 1 2

1

2 3 4 5 6 7 8 9 0

0

9

CLLYVL6438NS

24 V

A

C

24 V

AC COM

E G

N

D

SHLD SBUS

1

SBUS

2

NET

-1

NET

-2

DO

-1

DO

-2

CO

M

CO

M

CO

M

CO

M

DO

-3

DO

-4

DO

-5

DO

-6

DO

-7

DO

-8

AO

-1

AO

-2

AO

-3

DI

-1

DI

-2

DI

-3

DI

-4

20

V

D

C

UI

-1

UI

-2

UI

-3

UI

-4

UI-

5

UI

-6

CO

M

CO

M

CO

M

CO

M

CO

M

CO

M

TERMINALS 21-40

TERMINALS 9-20

TERMINALS 1-8

LonWorks Bus Jack

(labelled SRV JCK)

Neuron Service Pin

(labelled SRV PIN)

HOST STATUS LED

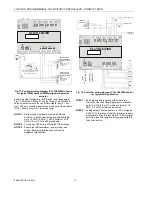

Fig. 13. LED, LonWorks® Bus Jack, and Neuron® Service

Pin for the CLLYUL6438S, CLLYVL6436AS, and

CLLYVL6438NS (CLLYVL6438NS shown)

1 2

3

3

4

4

5 6 7 8 9 0

9

9

1 1 1 1 1 1

2 2

2

2

2

1

3

6 7

9 0

4 5

1 1

1

1 1

1 2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9 0 1

1 1

2

DO

-4

24 V

A

C

24 V

A

C

C

O

M

E GN

D

20VD

C

SB

U

S

1

SB

U

S

2

NE

T

-1

NE

T

-2

DO

-3

CO

M

CO

M

24 V

A

C

24 V

A

C

C

O

M

E GN

D

20VD

C

SB

U

S

1

SB

U

S

2

NE

T

-1

NE

T

-2

DO

-1

DO

-2

AO

-1

AO

-2

UI

-1

*

UI

-2

UI

-3

UI-

4

CO

M

CO

M

CO

M

CO

M

DO

-1

CO

M

AO

-1

CO

M

CO

M

UI-

1

DO

-2

TERMINALS 1-12

TERMINALS 1-8

TERMINALS 13-24

TERMINALS 13-20

NEURON SERVICE PIN

(LABELLED SRV PIN)

NEURON SERVICE PIN

(LABELLED SRV PIN)

LONWORKS BUS JACK

(LABELLED SRV JACK)

LONWORKS BUS JACK

(LABELLED SRV JACK)

CLLYVL4024NS

CLLYUL1012S

Fig. 14. Terminal connections, Neuron® Service Pin, and

LonWorks® Bus Jack for the CLLYUL4024S,

CLLYVL4022AS, and CLLYVL4024NS (CLLYVL4024NS

shown left) and the CLLYUL1012S (right)

Wiring Applications (Examples)

Fig. 15 through Fig. 21 illustrate controller wiring for the

following configurations.

Typical controller wiring for VAV application using the

CLCM4T111 Wall Module and an LF20 Air Temperature

Sensor (see Fig. 15).

Typical controller wiring for VAV application with staged

reheat (see Fig. 16).