LYNX LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

EN0Z-0957GE51 R0615

8

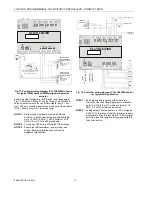

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

9

9

9

OUTPUT DEVICE POWER

TRANSFORMER

120/240 VAC

COM

24 VAC

EARTH GROUND

(TERMINAL 3)

EARTH GROUND

(TERMINAL 3)

EARTH GROUND

(TERMINAL 3)

EARTH

GROUND

WHEN CONNECTING POWER TO THE LYNX LON

CONTROLLER, CONNECT THE COM LEG OF THE VAC

SECONDARY CIRCUIT TO A KNOWN EARTH GROUND.

CONNECT POWER TO

TERMINALS 1 AND 2.

CONNECT POWER TO

TERMINALS 1 AND 2.

CONNECT POWER TO

TERMINALS 1 AND 2.

Fig. 11. Power wiring details for two or more LYNX

controllers per transformer

Communications

Refer to L

ON

W

ORKS

® Mechanisms (EN0B-0270GE51) for a

complete description of LonWorks® Bus network topology

rules and approved cable types.

Cable types for L

ON

W

ORKS

® Bus communications wiring are

Level IV 22 AWG (0.34 mm2) plenum or non-plenum rated

unshielded, twisted pair, stranded conductor wire.

For non-plenum areas, U.S. part AK3798 (single-pair

stranded) can be used.

In plenum areas, U.S. part AK3797 (single-pair stranded)

or U.S. part AK3799 (two-pair stranded) can be used.

Contact Echelon Corp. Technical Support for the

recommended vendors of Echelon-approved cables.

Communications wiring can be run in a conduit, if needed,

with non-switched 24 VAC or sensor wiring. If a longer

L

ON

W

ORKS

® Bus network is required, a Q7751A,B router

(configured as a repeater) can be added to extend the length

of the L

ON

W

ORKS

® Bus. Each network segment can have a

maximum of one repeater.

Pull the cable to each controller on the L

ON

W

ORKS

® Bus and

connect to the controller's communication terminals 7 and 8

(see also Fig. 12).

NOTE:

Connection for operator access to the L

ON

W

ORKS

®

Bus is provided by plugging the Serial L

ON

T

ALK

®

Adapter (SLTA) connector into the L

ON

W

ORKS

®

Bus Jack (see also Fig. 13).

IMPORTANT

All field wiring must conform to local codes and

ordinances (or as specified on installation drawings).

IMPORTANT

Do not bundle device output wires with sensor, digital

input, or communications L

ON

W

ORKS

® Bus wires.

IMPORTANT

Do not use different wire types or gauges on the same

L

ON

W

ORKS

® Bus segment. The step change in line

impedance characteristics causes unpredictable

reflections on the L

ON

W

ORKS

® Bus.

IMPORTANT

In noisy (high EMI) environments, avoid wire runs

parallel to noisy power cables, motor control centers,

or lines containing lighting dimmer switches. Keep at

lest 76 mm of separation between noisy lines and the

L

ON

W

ORKS

® Bus cable.

IMPORTANT

The theoretical limit for each L

ON

W

ORKS

® Bus

segment is 60 controllers. When a repeater is used

and the bus is either singly or doubly terminated, up to

120 controllers can be configured. Actual installations

may have a lower limit, depending upon the devices

connected.

IMPORTANT

The singly terminated bus must have one 209541B

FTT Termination Module for T tap or Star

configurations.

IMPORTANT

The doubly terminated bus must have two 209541B

FTT Termination Modules, one at each end of the

daisy chain (bus-style) wiring run. NOTE that the

Q7751A,B router (configured as a repeater) has

onboard terminating networks that can be jumper-

selected on each segment.

IMPORTANT

Make sure that neither of the L

ON

W

ORKS

® Bus wires

are grounded.

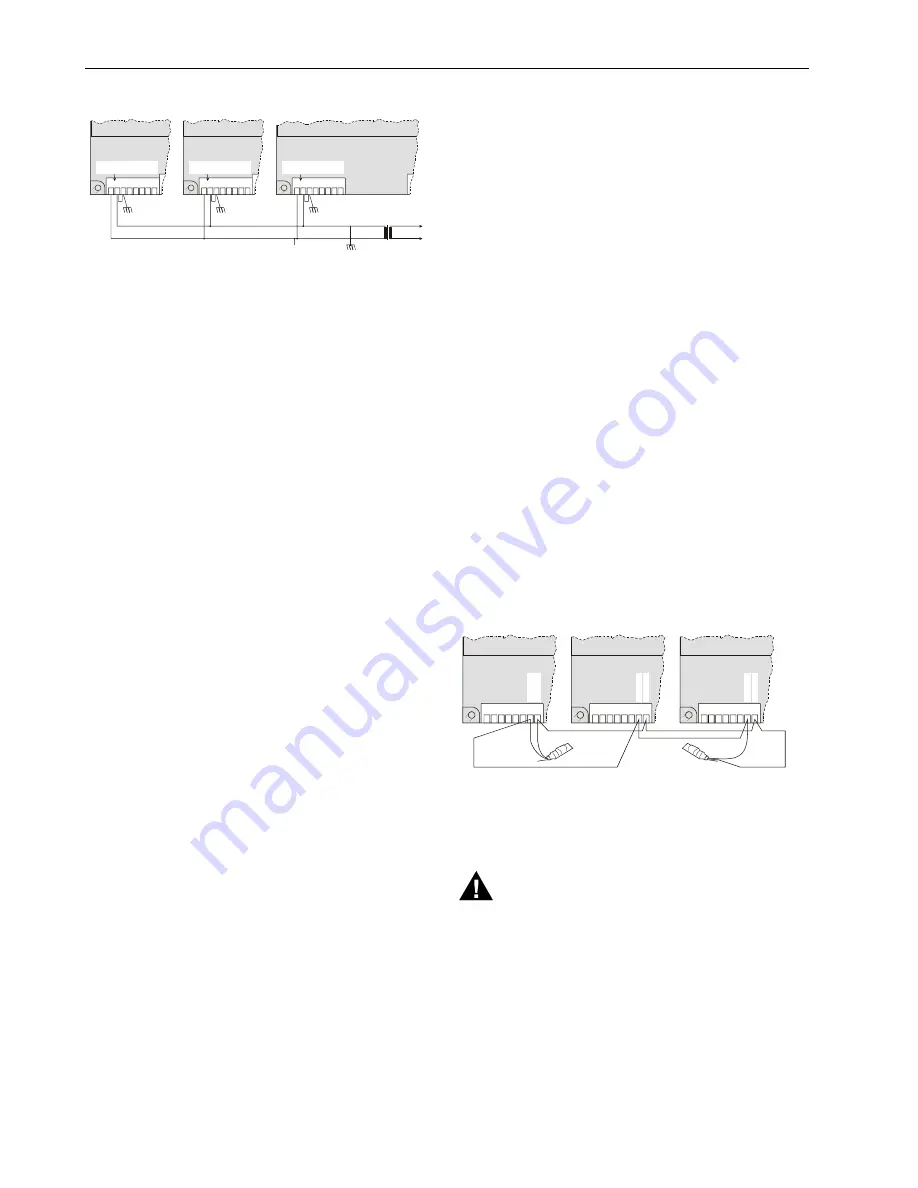

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

9

9

9

NOTE: ALL LONWORKS CONNECTIONS ARE

MADE TO NET-1 AND NET-2.

NET

- 1

NET

- 1

NET

- 1

NET -

2

NET -

2

NET -

2

BROWN

BROWN

ORANGE

ORANGE

Fig. 12. Termination modules (L

ON

W

ORKS

® daisy chain

connections)

WARNING

Fire, Explosion, or Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to modify the physical or electrical

characteristics of this device in any way. If trouble-

shooting indicates a malfunction, replace the

controller.