3

Floating/2-Position Run Mode

If the function selection switch has been set to one of the two

floating/2-position control settings—and if the actuator is wired

correspondingly (see Fig. 7, Fig. 8, and Fig. 9)—then as soon as

operating power is applied, the shaft adapter will run according to

the control signals applied.

Table 1 describes the behavior (“stops,” rotates “CCW,” or

rotates “CW”) of the CN6105/CN6110 in dependence upon the

control signals (switch “open” or “24 Vac/dc”) applied to terminals

3 and 4, the function selection switch setting, and the manner in

which the actuator is wired (either for floating mode: see Fig. 7;

or for 2-position mode: see Fig. 8).

Table 1. Behavior of CN6105/CN6110

wiring

control signal at

switch setting

term 3

term 4

Dir

Service/ Off

Rev

float. open open stops stops stops

open

24Vac/dc

CCW

stops

CW

24Vac/dc

open

CW

stops

CCW

2-pos. 24Vac/dc open

CW

stops

CCW

24Vac/dc 24Vac/dc

CCW stops

CW

Table 2 describes the behavior (“stops,” rotates “CCW,” or

rotates “CW”) of the CN4605/CN4610 in dependence upon the

control signals (switch “open” or “230 Vac”) applied to terminals 1

and 3 and the function selection switch setting: only one manner

of wiring is permitted (see Fig. 9).

Table 2. Behavior of CN4605/CN4610

control signal at

switch setting

term 1

term 3

Dir

Service/ Off

Rev

open open

stops

stops

stops

open 230

Vac

stops

stops stops

230 Vac

open

CW

stops

CCW

230 Vac

230 Vac

CCW

stops

CW

MANUAL ADJUSTMENT

IMPORTANT

To prevent equipment damage, before manual

adjustment, you must remove power or set the func-

tion selection switch to the “Service/Off” position.

After removing power or setting the function selection switch to

the “Service/Off” position, the gear train can be disengaged using

the declutch button, permitting the shaft adapter to be manually

rotated to any position.

Limitation of Rotation Stroke

Two adjustable mechanical end limits are provided to limit the

angle of rotation as desired (see Fig. 3). The mechanical end

limits must be securely fastened in place.

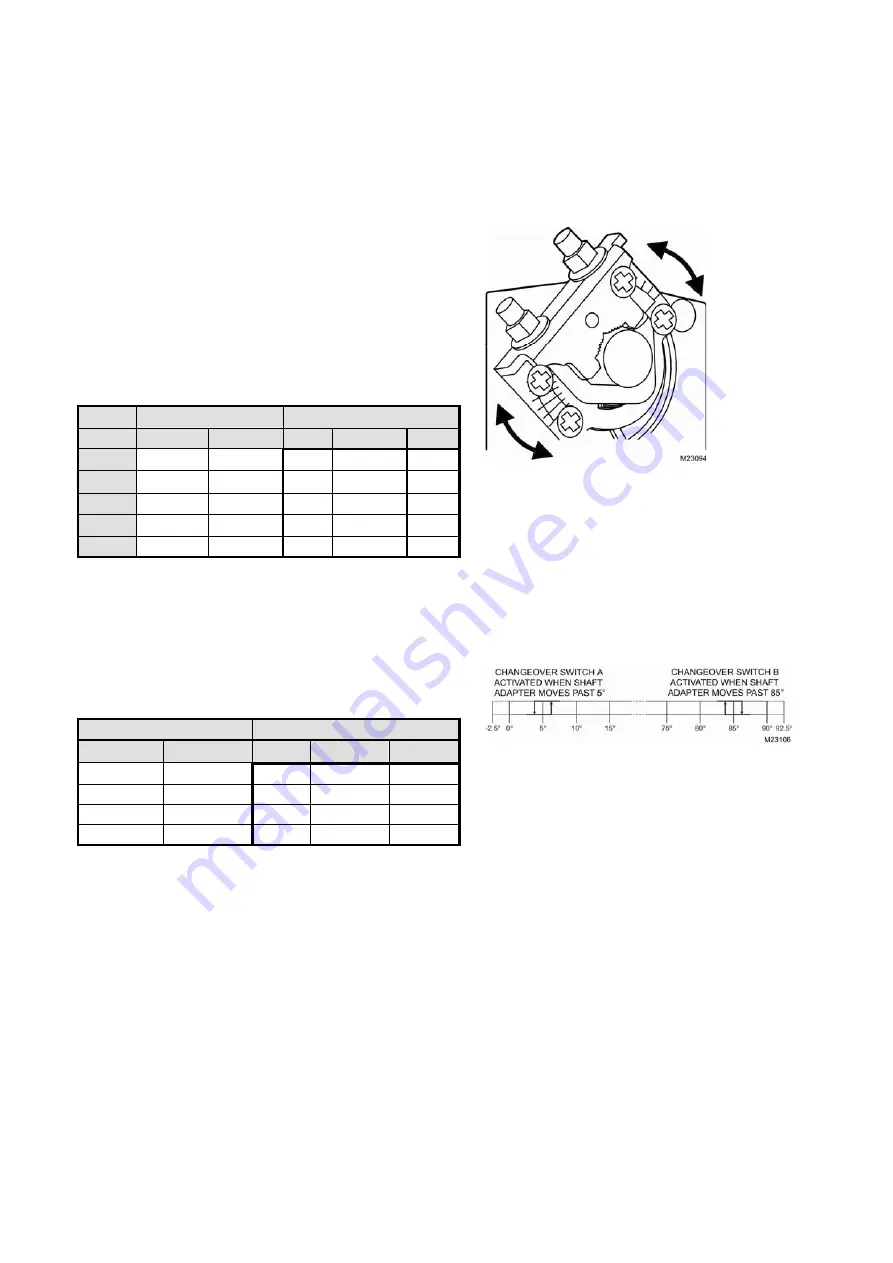

Fig.3. Mechanical end limits

To ensure tight closing of the dampers, the shaft adapter has a

total rotation stroke of 95°.

INTERNAL END SWITCHES

The internal end switches “A” and “B” are changeover switches

which are activated when the shaft adapter moves past a position

of 5° and 85°, respectively (see also Table 5).

Fig.4.

Internal end switch triggering points

CN0B-0544CH33 R0805B

CN05,CN10 SERIES DAMPER ACTUATORS FOR FLOATING/2-POSITON CONTROL