R7999C CONTROLINKS™ CONTROLLER

32-00081EF—01

8

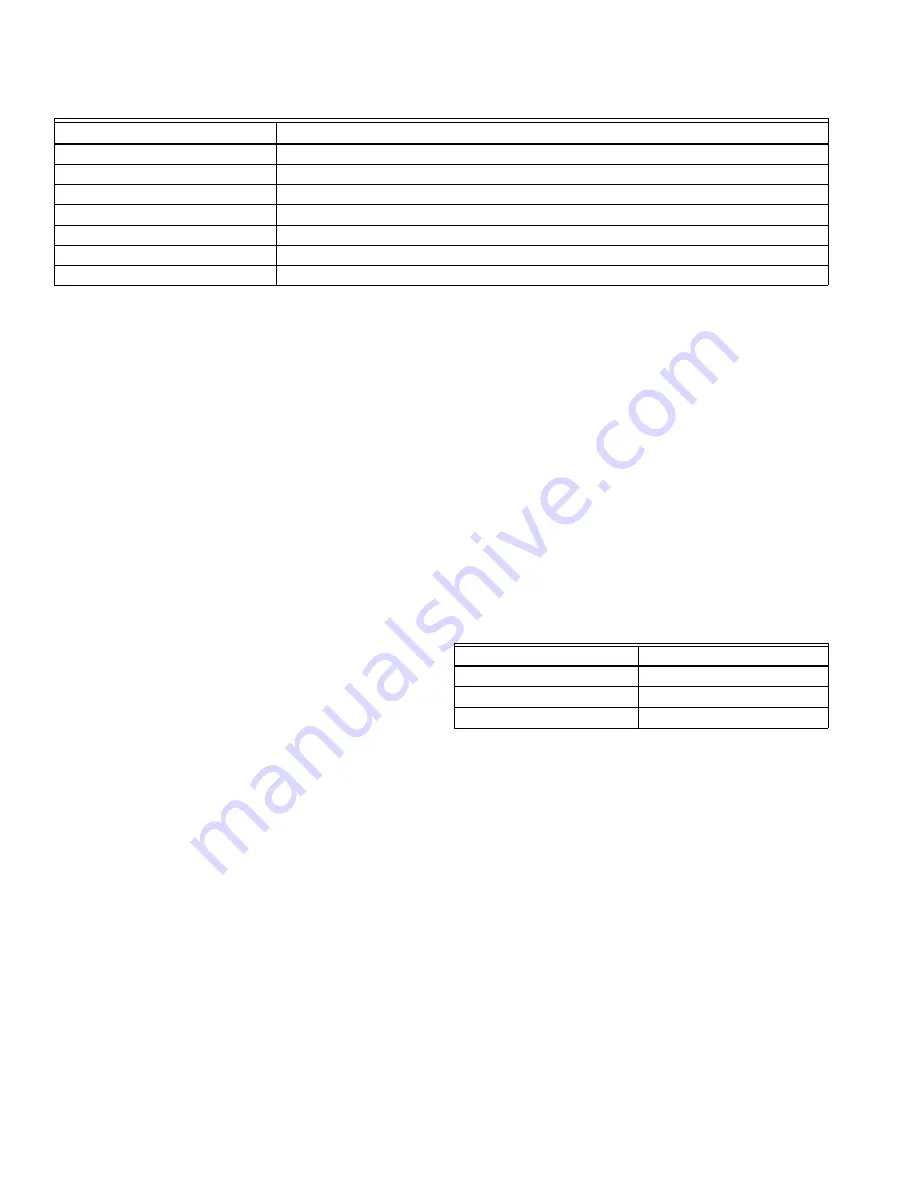

Table 5. R7999C Channel Status LED Blink Patterns.

a

The four amber motor LED provide status for the individual ML7999C Actuators; e.g., Motor 1 LED is Air Actuator Status,

Motor 2 LED is Fuel 1 Actuator Status, Motor 3 LED is Fuel 2 Status, and Motor 4 LED is FGR Actuator Status.

Manual Operation

Place the R7999C in a manual firing rate condition by

applying line voltage to terminal 4. The R7999C will drive to

the desired firing rate control position by the value of the

resistance set at terminal 36/38. A 200-Ohm value equals

minimum modulation; 4500 ohms equals maximum

modulation. Linear interpolation exists for all other values.

Commissioning Process

The primary tasks to be accomplished by the

commissioning process are as follows:

1.

Establish the endpoints of each actuator within the

system.

2.

Establish the purge position.

3.

Establish the lightoff position.

4.

Establish minimum and maximum modulation posi-

tions.

5.

Establish a fuel, air, FGR mixture profile for up to 20

points between the minimum and maximum modula-

tion points for each fuel source within the system.

The commissioning process requires either the S7999

touchscreen display, or the use of the ZM7999

ControLinks™ Commissioning Software running on a

laptop or PC with a minimum operating system of Windows

95. Additional minimum requirements include a Pentium®

class processor, or equivalent, with 16megabytes of RAM

and a one gigabyte hard drive with 100 megabytes of free

hard drive memory. The PC or laptop must have a serial or

USB port. If using a serial port, an RS232-to-RS485

converter (like the QM4520) is required to communicate

with the R7999C. Shielded cable is recommended as

interface wiring.

If using a USB port, a Keyspan® or Belkin® USB to RS-485

converter is recommended.

The R7999C requires the presence of one of the Fuel Select

inputs to start communications with the ZM7999

ControLinks™ Commissioning Software. Additional wiring

interface requirements include that HF and LF command

inputs cannot be activated at the same time.

NOTE:

A stack gas analyzer is required to commission the

ControLinks™ Control System.

Table 6. RS-485 to R7999C Hookup Data.

Figs. 4 and 6 provide a standard block hookup diagram for

the R7999C and associated equipment.

Motor (Amber) LED State

a

Meaning

Always Off

Actuator is not being commanded to move or is not configured.

On

Actuator is in motion.

1 short blink every interval.

Actuator Failure: Failed timing plausibility check.

2 short blinks every interval.

Actuator Failure: Failed actuator ID process.

3 short blinks every interval.

Actuator Failure: Analog/Digital reading of potentiometer out of range.

4 short blinks every interval

Actuator Failure: Potentiometer failure—wiper resistance.

Medium speed blink.

Actuator Warning: Wiper resistance high.

RS-485

Connects to R7999C

Data+

A

Data-

B

Ground

C