WEB-300E, WEB-600E/U, CP-300E, CP-600E/U SERIES CONTROLLERS

31-00010—01

12

4.

Remove the metal shield and set it aside. To do this,

carefully pry up from the top (hole vented side) first,

then push out the other side to slip the port holes

past the port edges. Then lift the shield up and

away.

NOTE: Be mindful of the “side clips” on the control-

ler’s two Ethernet ports.

5.

Use a 1/4 in. (7 mm) nutdriver to unscrew the four

metal standoffs, and set them aside.

6.

Carefully pry up the NPM3E or NPM6E processor

module board, noting that the two-row, 50-pin con-

nector is on the option card side. Keep the board

level as you work it loose from this connector.

7.

Set the processor module board aside. Note the

jumper block on the base board behind the RS-485

port (see bottom of Fig. 7).

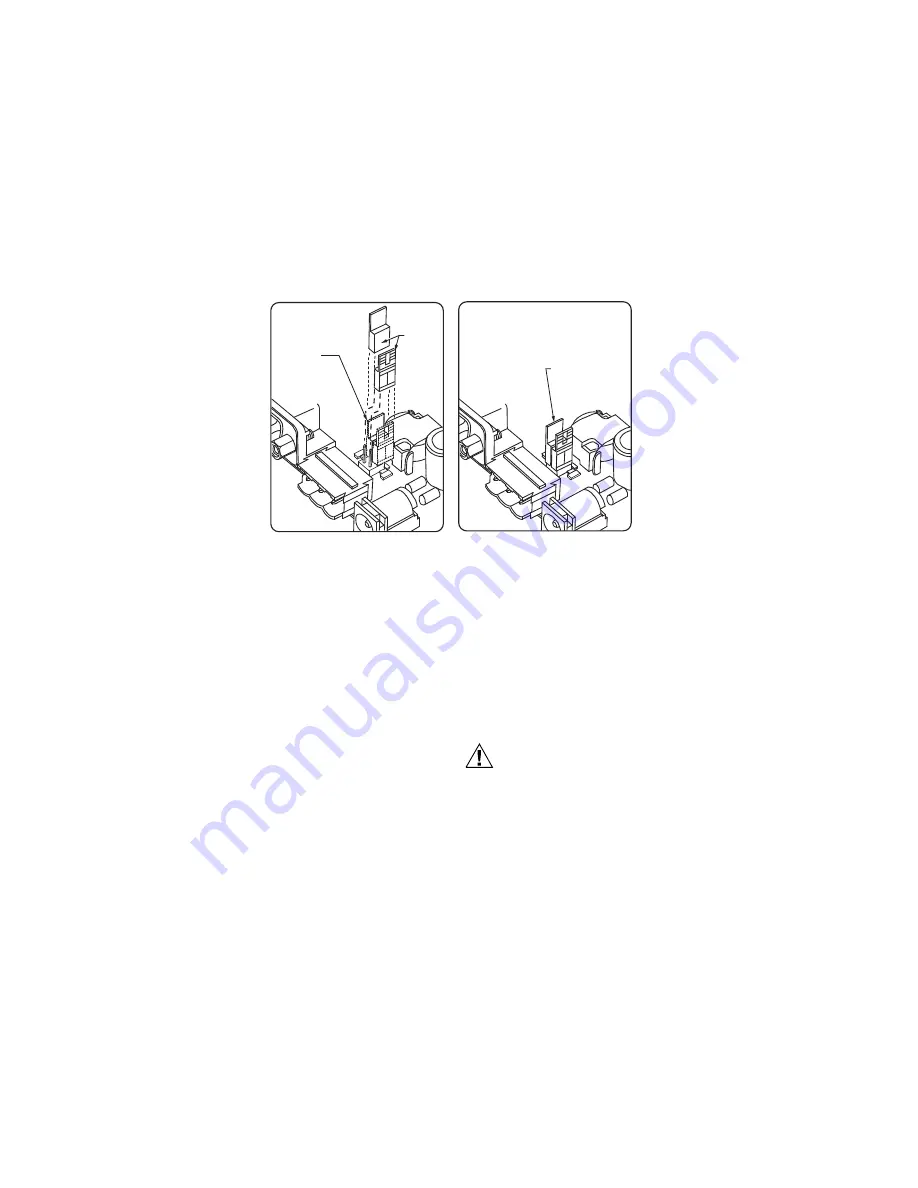

Fig. 8. Install shorting blocks across both sides of jumper block to add RS-485 bias.

Installing shorting blocks to add

RS-485 biasing.

1.

Locate the four jumper pins behind the RS-485 port,

with 2-pin shorting blocks installed on one pin each.

See Fig. 8.

2.

To add biasing, remove and replace both shorting

blocks back onto the jumper pins, as shown in Fig. 8.

Reassembling the controller.

1.

Carefully replace the processor module board onto

the 50-pin connector, with its corner mounting holes

aligned on the four lower standoffs. Press down on

the connector to fully seat the board. See Fig. 7 on

2.

Refasten the four metal hex standoffs, hand tighten-

ing with a 1/4 in. (7 mm) nutdriver.

3.

Replace the shield back onto the unit. To do this,

carefully ease it over the port side first, then spring it

down over the other side. Make sure that its corner

holes align with the metal standoffs below.

4.

Refasten the four Phillips head screws that secure

the shield to the standoffs.

5.

Replace the plastic cover onto the unit.

POWER UP AND INITIAL

CHECKOUT

Ensure power wiring to the controller is ready—see

“Power Wiring” on page 7. See Fig. 3 page 4 for the

location of status LEDs and connectors. See Fig. 4 on

page page 8 for the location of the NPB-PWR-H/U

module’s power connector.

After completing all mounting and wiring, do the following:

Initial power up and checkout.

1.

Apply Power.

2.

Check the Status LED.

Also see the section “About Backup Configurations” on

Apply Power

To apply power, insert the power plug into either the NPB-

PWR-H/U module, or if using a NPB-WPM-US/U wall

adapter, the controller. If using the line-voltage input NPB-

PWR-UN-H/U power supply module, energize the 120–

240Vac circuit wired to the module.

CAUTION

Do not connect both the NPB-WPM-US/U and

NPB-PWR-H/U / NPB-PWR-UN-H/U supplies at

the same time, or equipment damage may

result.

Check the Status LED

When power is applied, the green LED labeled “STATUS”

will light. This indicates that the system is OK, with power

applied. When the controller finishes booting, the yellow

“BEAT” LED should be blinking steady at a 50% duty

cycle, typically at a 1Hz rate. In most cases, this blink

pattern starts about 30 seconds after power is applied.

If after applying power, the STATUS LED goes out, or if

the BEAT LED comes on (steady) and stays lit over 2

minutes, seek technical assistance. See the section “LED

Status Indicators” on page 13, especially “Heartbeat”.

POSITION OF

PRE-INSTALLED

SHORTING BLOCKS

(NO BIASING)

SHORTING BLOCKS

INSTALLED ACROSS

JUMPER PINS

(BIASING ADDED)

SHORTING

BLOCKS

LIFTED

AWAY

M34996