WEB-600E AND CP-600E NETWORK CONTROLLERS

62-0433—01

16

REPLACEMENT PARTS

Servicing the WEB-600E controller may call for replacement

parts. There are three categories of parts:

Non-replaceable Parts

Other than the parts listed in the replacement parts sections,

there are no serviceable components on the base assembly.

Memory

Any addition, modification, or replacement of memory

components requires software configuration and is not a field

upgrade. For additional information on modifying the memory

capacity of the controller, consult your regional Tridium office.

FUSE

The controller contains a non-user replaceable fuse, soldered

on the circuit board. This fuse provides protection from

internal shorts or connection to incorrect power supplies. If the

fuse circuitry is suspect, contact your regional Tridium office

for technical support. See “Returning a Defective Unit” on

Standard Replacement Parts

Standard replacement parts are listed in Table 4, and can be

ordered from stock without restriction. Standard replacement

parts cannot be returned for credit and should be disposed of

in an appropriate manner.

New Replacement Unit

To replace an entire unit, order and install a

new

WEB-600E

controller. If the faulty controller is

still in warranty

, you can

receive credit by returning it. Be sure to contact the vendor for

a return authorization (RA) number before shipping an item for

return credit. See “Returning a Defective Unit” on page 17, for

more details.

NOTE: Before ordering a new controller, it is strongly

recommended that you contact your normal

technical support resource to eliminate the pos-

sibility of a software issue or mis-configuration

problem.

Replacing the Controller Base

Assembly

NOTE: Before handling circuit boards, discharge any

accumulated static by touching a nearby earth

ground. For details, see “Static Discharge Pre-

To replace a WEB-600E with a new replacement unit, proceed

as follows:

1.

If possible, use the appropriate WEBs-AX software tool

to back up the controller’s configuration to your PC.

2.

Remove power to the controller. The unit should power

down automatically. Wait for all LEDs to remain off.

NOTE: If IO accessory modules are installed, and any I/

O points have voltage, turn the devices off or dis-

connect power to them.

3.

Note positions of all communications and other wiring

cables going to the controller, as well as installed acces-

sory modules (if they must be removed). If necessary,

label connectors and accessory modules to avoid mis-

connection later, after the controller is replaced.

4.

Unplug all Ethernet, serial, LON, modem, and I/O con-

nectors from the controller.

5.

If IO accessory modules are installed:

— If DIN rail mounting with DIN end-clips was used, you

may be able to remove the DIN rail end clip that

secures the WEB-600E end of the assembly, and then

slide the controller away from the rest of the assembly.

Then you can remove the controller from the DIN rail

(see Fig. 2), leaving the mounting and wiring of IO

modules untouched.

In this case, after removing the controller from the DIN

rail, go to 6.

— If tab (screw) mounting was used

instead

of DIN rail

mounting, or if a combination of DIN mounting and tab

screws was used (into the controller’s “accessory side”

tab holes, see last page), you will need to remove

accessory modules

first

, before removing the control-

ler. In this case:

a. Making a careful note of all wiring terminations,

unplug the I/O connector plugs and earth ground

wires from the installed IO modules.

b. Remove the installed accessory modules, starting

with the end module.

c. c Remove any screws fastening the controller, and

remove it (see Fig. 1).

6.

Remove the cover of the old unit. See “Removing and

Replacing the Cover” on page 5. Note the position of

installed option cards, if any. You must transfer them to

the replacement controller.

7.

Remove any option cards from the old controller and

install them into the replacement WEB-600E controller,

if applicable. See “Installing an Option Card” on page 7

for more details.

8.

Check the RS-485 biasing jumpers on the existing unit,

and duplicate on the replacement unit (see “Installing an

9.

Mount the replacement controller as it was previously,

using the same DIN rail location and/or screws.

10.

Reconnect/remount any removed accessory modules,

being careful to replace in the same order, using the

same DIN rail location and/or screws. Secure all mod-

ules as done previously.

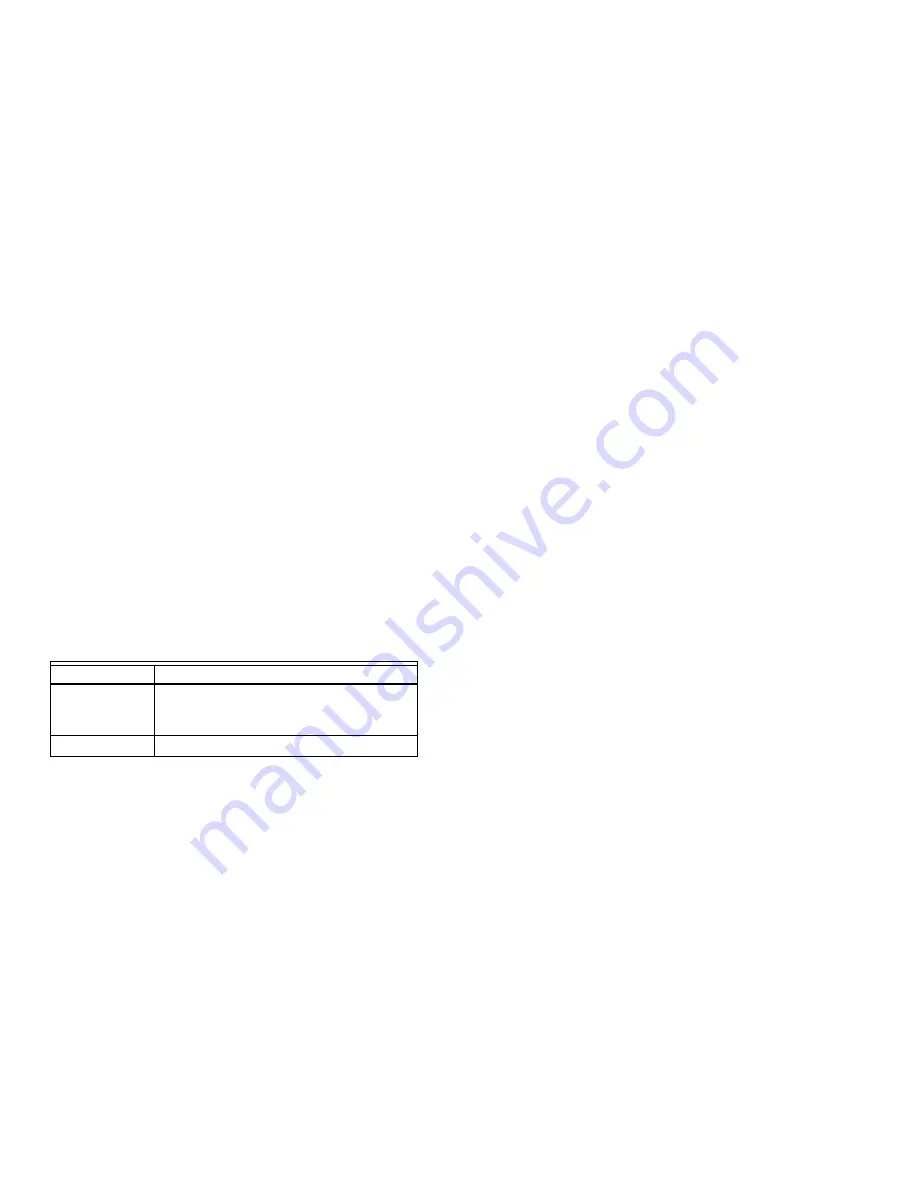

Table 4. Standard replacement parts

for a WEB-600E controller.

Part Number

Description

WEBs-AX

Optional NiMH Battery Pack—see “NiMH

Battery Installation and Maintenance” on

H10027

RS-485 connector plug, 3-position.