ENS7003R16 KO65 2013

1

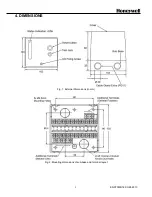

DIGITAL BURNER CONTROLLER

DBC2000 SERIES

1. APPLICATION

The Honeywell DBC2000 is a microprocessor-based

integrated burner controller for automatically fired

gas, oil or combination fuel industrial single burner

power burner applications. The DBC2000 system

consists of the relay module and wiring subbase.

The DBC2000 Standard Model provides the

minimum requirements to control an industrial

burner system, such as automatic burner

sequencing, flame supervision, system status

indication, system or self-diagnostics and

troubleshooting. The DBC2000 Enhanced Model

includes an integrated Valve Proofing System,

whilst the Ultimate model includes bus

communication on top of this.

The DBC2000 is programmed to provide a level of

safety, functional capability and features beyond

the capacity of conventional controls.

2. FEATURES

•

Employs a plug-in mounting method

•

Uses a microprocessor to improve performance

•

Status and fault indication by indicator LEDs

•

A 4-wire firing rate switching circuit controls an air

damper motor or other auxiliary equipment during

start-up of the burner.

•

Safe start check before and during pre-purge

•

Dual flame amplifier for UV, IR or flame rod sensor

•

Automatic recycle once per 24h of uninterrupted

heat demand.

•

Frontal jack plug (Ø 3.5mm) to read the flame

signal with a microampere meter.

•

An electrical sub base lock (reset and safety limit

terminals are swapped) to avoid that a Standard

model is used systems wired for an Enhanced or

Ultimate model. The DBC2000 cannot start then.

•

Safety shutdown occurs on

-

malfunction of the burner controller

-

failure to ignite the pilot burner or main burner

-

loss of flame during run period

-

opening of air flow switch during pre-purge, start-

up, run and post-purge period

-

flame signal detection during standby or pre-

purge period

•

Integrated Valve Proofing System (Enhanced and

Ultimate models only)

•

Remote bus communication (Ultimate model only)

Contents

1. Application

1

2. Features

1

3. Specifications

2

4. Dimensions

5

5. Installation and wiring

6

6. Operation

12

7. Trouble shooting

14

8. Approvals and Maintenance

23

Appendix: VPS calculation and diagrams

25

PRODUCT HANDBOOK

Important note:

Subject to changes without notice.

Please check our web site

http://hic.emea.honeywell.com

for the most recent version of this document.

All rights reserved.

Summary of Contents for DBC2000E10 Series

Page 13: ...ENS7003R16 KO65 2013 13 ...

Page 15: ...ENS7003R16 KO65 2013 15 ...

Page 16: ...ENS7003R16 KO65 2013 16 ...

Page 17: ...ENS7003R16 KO65 2013 17 ...

Page 18: ...ENS7003R16 KO65 2013 18 ...

Page 19: ...ENS7003R16 KO65 2013 19 ...

Page 20: ...ENS7003R16 KO65 2013 20 ...

Page 21: ...ENS7003R16 KO65 2013 21 ...

Page 27: ...ENS7003R16 KO65 2013 27 ...

Page 28: ...ENS7003R16 KO65 2013 28 ...

Page 29: ...ENS7003R16 KO65 2013 29 ...

Page 30: ...ENS7003R16 KO65 2013 30 ...

Page 31: ...ENS7003R16 KO65 2013 31 ...

Page 32: ...ENS7003R16 KO65 2013 32 ...

Page 33: ...ENS7003R16 KO65 2013 33 ...

Page 34: ...ENS7003R16 KO65 2013 34 ...