Chapter 8. PROGRAM SETUP

8-9

■

Setting up PID set No. items

(1) In the setting display state, move to the PID set No. items of the segment to be set up

on the programming map.

(2) If you press

ENT

, the lower display starts blinking to indicate start of entry to the

No.1 setup.

(3) Press

,

,

or

to set to the No.1 setup PID set No. setting.

Setting range: 0 to 8 (non heat/cool models)

0 to 4 (heat/cool models)

(4) When you press

ENT

, blinking on the upper display stops.

●

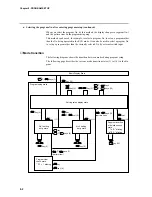

Display

PID set No. setting value

Program No.

Segment No.

Pattern

tendency

EV1 to EV3 and T1 to T5 all out

P

I

D

• When setup data

C

1

1

is set to 1 and PID set auto-switching ON is selected, the PID set

No. items on the programming map are skipped and not displayed.

• On 5G output models, when setup data

C

1

8

is set to 1 and programmer functions are

selected, the PID set No. items on the programming map are skipped and not dis-

played.

• On 3D output models, when setup data

C

4

5

is set to 1 and 3-position-proportional

control is selected, the PID set No. items on the programming map are skipped and not

displayed.

• When setup data

C

7

0

is set to 1, the PID set No. items on the programming map are all

skipped and not displayed.

• When the PID set No. setting is set to 0, this means that the PID set No. of the previous

segment is continued. When the PID set No. setting is set to 0 in the No.1 segments,

this is the same as being set to 1.