4-2

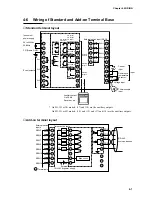

• Before wiring the DCP301, check the controller catalog No. and terminal Nos.

on the label on the rear of the body. After wiring the DCP301, be sure to check

the wiring for any mistakes.

• Maintain a distance of at least 50cm between I/O leads or communications

leads and the power lead. Also, do not pass these leads through the same

piping or wiring duct.

• When wiring with crimped terminals, take care to prevent contact with adjacent

terminals.

• When connecting the DCP301’s thermocouples in parallel to other controllers,

make sure that the total input impedance of the other controller is at least

1M

Ω

.

If the input impedance is less than 1M

Ω

, the DCP301 may not be able to detect

sensor disconnection.

• When inputting the DCP301’s I/O (parallel connection in case of input) to an A/

D converter or analog scanner, read data may fluctuate.

To prevent this, adopt one of the following measures.

(1) Use a low-speed, integrating type A/D converter.

(2) Insert an isolator without a switching power supply between the DCP301

and A/D converter.

(3) Average data on a personal computer when reading data.

(4) If possible, set a filter for the input.

• Provide the wiring for the instrument power supply with a mains power shutoff

switch within reach of the instrument operator.

• Provide the wiring for the instrument power supply with a delayed operation

type (T) 1A current rating, 250V voltage rating fuse. (IEC 127)

• Devices and systems to be connected to this unit must have the basic insula-

tion sufficient to withstand the maximum operating voltage levels of the power

supply and input/output parts.

Handling Precautions