Installation Guide

69-2089EFS—08

10

Problem

Recommended Troublshooting Steps

No dehumidification, neither fan

nor compressor run with fan

switch and ventilation timer OFF.

1. Unit unplugged or no power to outlet.

2. Humidity control set too high or defective.

3. Loose connection in internal or control wiring.

4. Defective Compressor relay.

5. Defective control transformer.

6. Low pressure control open.

7. Optional Condensate Pump Safety Switch open.

No dehumidification, compressor

does not run but fan runs when

there is a call for dehumidification

and the ventilation control is OFF.

1. Defective compressor run capacitor.

2. Bad connection in compressor circuit.

3. Defective compressor overload.

4. Defective compressor.

5. Defrost thermostat open.

6. Optional Condensate Pump Safety Switch open.

Fan runs when there is a call for

dehumidification and the ven-

tilation control is OFF, but the

compressor cycles on and off too

frequently.

1. Low ambient temperature and/or humidity causing unit to cycle through

defrost mode.

2. Defective compressor overload.

3. Defective compressor.

4. Defrost thermostat defective.

5. Dirty air filter(s) or airflow restricted.

6. Low refrigerant charge, causing defrost control to cycle.

7. Bad connection in compressor circuit. Fan does not run with fan switch in

either position.

CAUTION:

Servicing the TrueDRY DH65 with its high pressure refrigerant system and high voltage cir

-

cuitry presents a health hazard which could result in death, serious bodily injury, and/or property damage.

Service should only be performed by a qualified service technician.

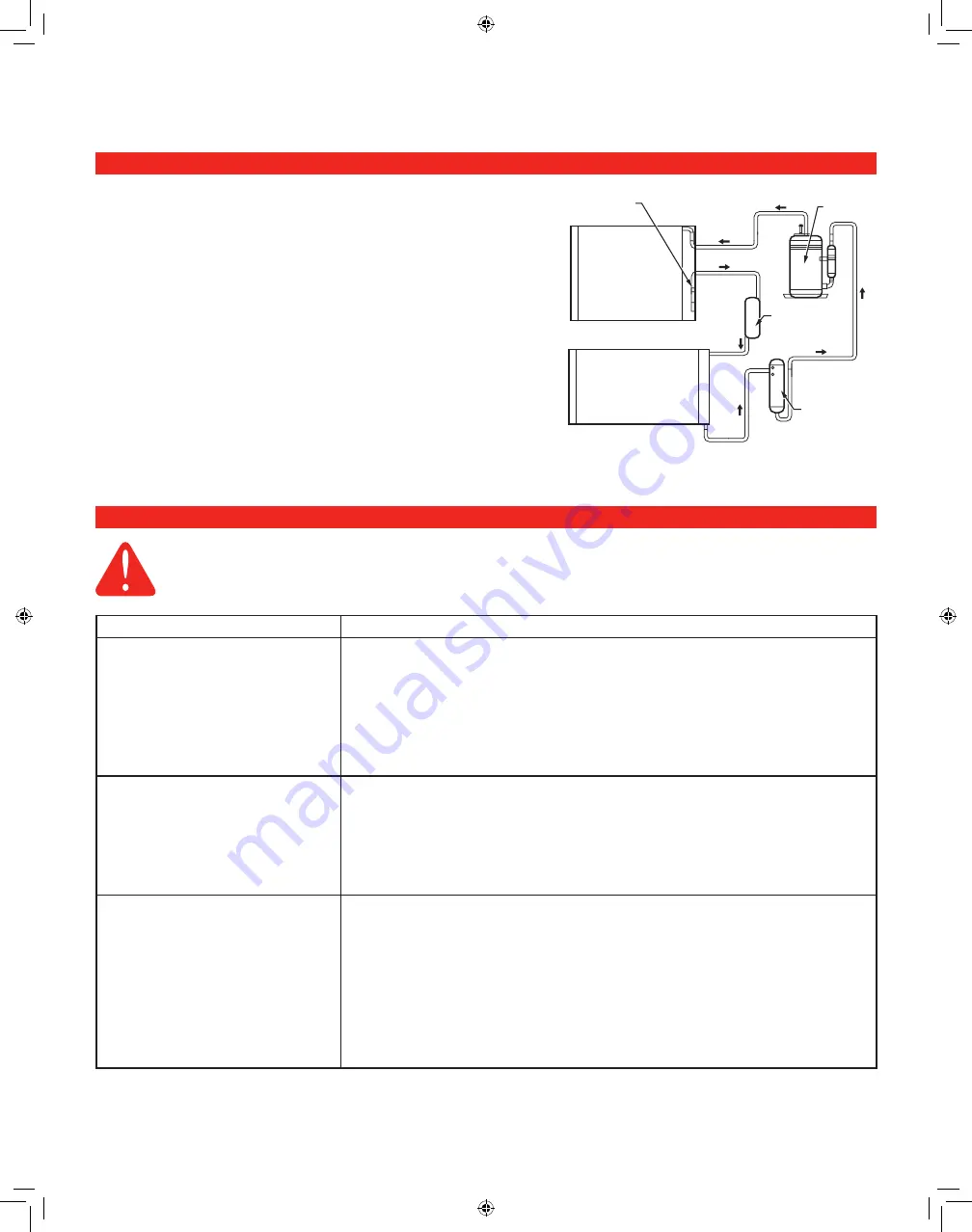

Technical Description

CONDENSER

EVAPORATOR

CAPILLARY

TUBES

ACCUMULATOR

COMPRESSOR

STRAINER/FILTER

DRIER

M27404

Troubleshooting

TrueDRY DH65 uses a refrigeration system similar to an air con

-

ditioner to remove heat and moisture from incoming air and add

heat to the air that is discharged. Hot, high-pressure refrigerant

gas is routed from the compressor to the condenser coil. The

refrigerant is cooled and condensed by giving up its heat to the

air that is about to be discharged from the unit. The refrigerant

liquid then passes through a strainer and capillary tubing which

causes the refrigerant pressure and temperature to drop. It next

enters the evaporator coil where it absorbs heat from the incom-

ing air and evaporates. The evaporator operates in a flooded con-

dition, which means that all the evaporator tubes contain liquid

refrigerant during normal operation. A flooded evaporator should

maintain nearly constant pressure and temperature across the

entire coil, from inlet to outlet.

69-2089EFS_D.indd 10

9/22/2008 10:02:41 AM