W

innox · Edition 12.20

EN-3

electrical Wiring

All the electrical wiring must comply with all applicable local codes

and/or standards such as:

– NFPA Standard 70

– IEC 60364

– CSA C22

– BS7671

Gas Piping

All the gas piping must comply with all applicable local codes and/

or standards such as

– NFPA Standard 54

– ANSI Z223

– EN 746-2

Where to Get the standards?

the nFPA standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

the AnsI standards are available from

American National Standard Institute

1430 Broadway

New York, NY 10018

www.ansi.org

the UL standards are available from

333 Pfingsten Road

Northbrook, IL 60062

www.ul.com

the FM standards are available from

1151 Boston-Providence Turnpike

PO Box 9102

Norwood, MA 02062

www.fmglobal.com/approvals

Information on the en standards and where to get them is

available from

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

www.cen.eu

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

www.cenelec.org

Checklist before installation

Intake

Provide an opening in the burner room of at least one square inch

per 4000 BTU/h (1,17 kW) to supply the burner intake with fresh,

outdoor, combustion air.

If there are corrosive fumes or materials in the surrounding air, find

an uncontaminated source to supply air to the burner, or provide a

sufficient air filtering system.

exhaust

Do not allow exhaust fumes to accumulate in the work area. Provide

some positive means for exhausting from the furnace and the building.

Access

Make sure that you install the burner in such a way that you can gain

easy access for inspection and maintenance.

environment

Make sure the local environment matches the original operating

specifications. Check the following items:

– Voltage, frequency and stability of the electrical power

– Fuel type and supply pressure of the fuel

– Availability of enough fresh, clean combustion air

– Humidity, altitude and temperature of air

– Presence of damaging corrosive gases in the air

– Prevent direct exposure to water

InstALL FLAMe sensoR

1

Install the flame sensor into the 1/2" NPT opening in the rear

cover.

2

Make sure that you connect the flame sensor of a burner to the

electrical circuit of that burner.

DAnGeR

– Connecting the flame sensor of a burner to the electrical circuit

of the wrong burner can result in a fire or explosion.

There are two different types of flame sensors; UV scanner and

flame rod.

UV scanner

➔

The UV scanner must be compatible to the flame monitoring

control that is used. Refer to the manual of your selected control

for proper selection of the scanner.

Flame Rod

note:

Only specific burner sizes with alloy or silicon carbide com-

bustors can use a flame rod, see Technical Information Winnox.

➔

For detailed information on how to install and connect a flame rod,

refer to Eclipse ignition components technical literature.

spark plug

➔

Install the spark plug into the opening in the rear cover.

note:

Do not apply any grease to the threads of the spark plug or

bad grounding of the spark plug may occur, resulting in a weak spark.

➔

If flame monitoring controls other than those recommended in

the Design Guide are used contact Eclipse to determine how the

burner performance may be affected, adjustments may vary from

Eclipse published values. Consult with the engineer who specified

the alternate control for limitations.

InstALL BURneR

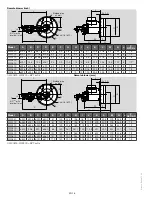

Chamber opening

1

Provide an opening in the chamber wall at least 1/2" (12 mm)

larger in diameter than the outside diameter of the combustor

(1/4"–6 mm per side).

➔

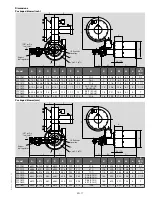

The combustor diameter can be found here: page 17 (Di-

mensions).

2

Provide an accessible pressure tap on the chamber wall to meas-

ure the pressure inside the firing chamber.

➔

The pressure tap should be located near the burner.

Chamber wall

Minimum

1/4" (6mm)

space per

side

Combustor

Slots

Chamber opening