W

innox · Edition 12.20

EN-6

ADJUstMent, stARt AnD stoP

In this chapter, you will find instructions on how to adjust, start, and

stop the burner system. Become familiar with burner control methods

before attempting to make adjustments.

DAnGeR

– The Winnox burners are designed to mix fuel with air and burn

the resulting mixture. All fuel burning devices are capable of

producing fires and explosions if improperly applied, installed,

adjusted, controlled, or maintained.

– Do not bypass any safety feature; fire or explosion could result.

– Never try to light a burner if it shows signs of damage or

malfunction.

step 1 - Reset the system

1

Set the low gas pressure switch to 20% below the “Fuel Inlet

Pressure” range as specified in the appropriate datasheet.

2

Set the high gas pressure switch to 20% above the “Main Gas

Inlet Pressure” range as specified in the appropriate datasheet.

3

Close all the burner gas valves - manual and automatic.

4

Try to ignite the burner; be sure the flame monitoring system in-

dicates a flame failure.

5

Activate the pressure switches and other limit interlocks. Be sure

the switches fail as intended in the event of a power failure.

DAnGeR

– If simulated limits or simulated flame failure do not shut down

the fuel system within the required failure response time,

immediately correct the problem before proceeding. Refer to

page 10 (Assistance in the event of malfunction).

6

If the burner is firing into a duct or chamber with a circulating fan,

start the fan to produce full process air flow past the burner.

7

Adjust main gas inlet pressure to the ratio regulator within the

range specified in the appropriate datasheet.

WARnInG

– Gas inlet pressures must stay within the specified range.

Pressure above the specified range can damage the ratio

regulator.

– Pressure below the specified range can impair the ability of the

ratio regulator to control the gas flow.

– Operating the system outside the specified range can cause

excess fuel consumption and the possible accumulation of

unburned fuel in the chamber.

– In extreme cases, this accumulation of unburned fuel may

cause fires or explosions.

8

Verify the actuator opens the air butterfly valve towards the back

of the burner as shown in figure "Air butterfly valve open direction".

If it doesn’t, refer to the actuator’s literature for instructions on

how to reverse the direction.

Closed

Open in this

direction

only

Open

Back

Air butterfly valve open direction

step 2 - set low fire air

1

Start combustion air blower.

2

Drive control motor to low fire position.

3

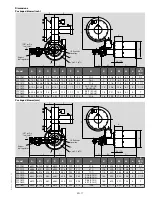

Measure the air differential pressure between tap

C

and the com-

bustion chamber.

note:

The pressure tap is in the open position when the screw

inside the tap is unscrewed approximately 1/2 turn. Do not remove

the screw. Be sure to tighten the pressure tap screw clockwise to

the closed position after pressure measurements have been taken.

To chamber

Manometer

Tap C

Air differential pressure

4

Set low fire air.

a

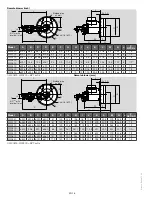

Loosen the set screw

A

on the burner side of coupling. There is

a slot in the end of the butterfly valve shaft that is parallel to the

air damper. This slot is used for visual indication of the butterfly

valve position. The butterfly valve is closed when the shaft slot is

perpendicular to the direction of air flow through the butterfly

valve.

b

Rotate the air butterfly valve shaft to a fully closed position. (Holes

in the butterfly valve will supply low fire air.)

c

When firing into a positive chamber pressure, rotate the air but-

terfly valve from the closed position in the direction of actuator

travel to obtain a minimum 0.3" w.c. (0,8 mbar) air differential

pressure.

d

Hold the butterfly valve shaft firmly in place and tighten set screw

2

.

➔

High fire air adjustment is not required if the burner is firing into

a neutral pressure chamber and a 90° travel control motor is

used. It may be necessary to limit control motor stroke to less

than 90° if firing into a large negative chamber. Contact Eclipse

for further information.

A

Control

motor

Coupling

Air butterfly valve adjustment

5

Verify high fire air:

a

Drive control motor to high fire, full open.

b

Compare the high fire air differential pressure between Tap

C

and

the combustion chamber to the approximate datasheet chart “Air

Δp vs. Input”. If high fire air is insufficient, refer to page 10

(Assistance in the event of malfunction).

6

Return the control motor to the low fire position.

7

Close the pressure taps.

BV shaft shown

in closed position

Air butterfly valve shaft