7

Edition 10.17

Technical Information · GB

• For direct and indirect heating

• Economical, energy-saving operation by

virtue of internal air preheating up to 650°C

• Uniform distribution of temperature by

means of a high burner impulse

• 7 sizes from 25 to 500 kW

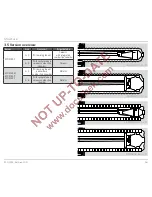

• Highly efficient with a ceramic burled tube recuperator or a cast

steel ribbed tube recuperator.

Self-recuperative burner ECOMAX for gas