ECOMAX · Edition 10.17

10

Application

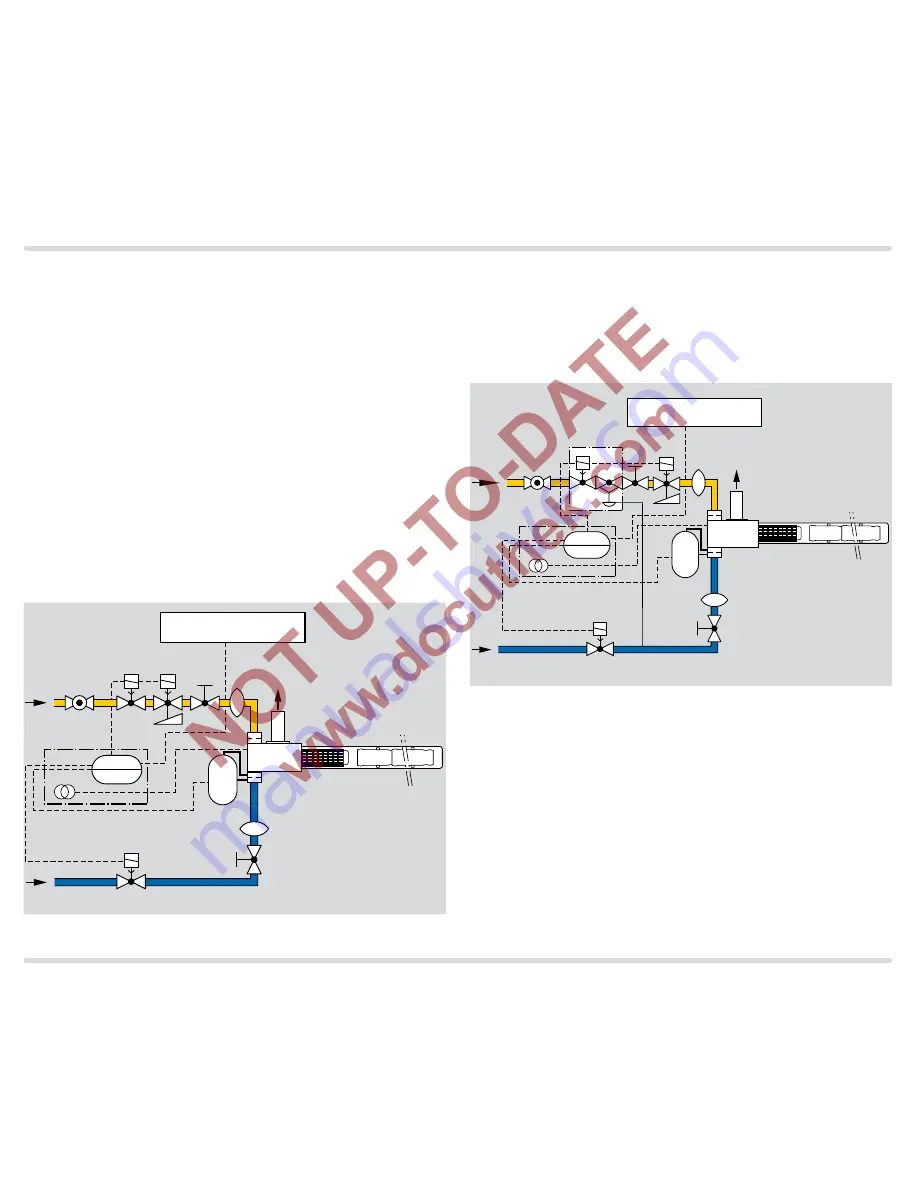

1 .5 .1 No pneumatic air/gas ratio control system

For indirect heating, slow opening gas valves and quick

opening air control valves are to be used to ensure a

safe burner start.

If there is no pneumatic air/gas ratio control system,

the gas and air pressures must be controlled and moni-

tored in the supply lines. Fluctuations in the supply

pressure affect the burner capacity and the air index

(lambda).

A system which includes air flow monitoring is recom-

mended to monitor pre-purge and as low air pressure

protection (pursuant to EN 746-2 and ISO 13577-2).

The ECOMAX is equipped with an integrated air orifice

which can be used for this.

VR..N

VMV

ECOMAX

VG

VG..L

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

PDZ

DG

AKT

1 .5 .2 Air/gas ratio control

The pneumatic air/gas ratio control system ensures

that changes in the air pressure in the air supply line are

compensated for by controlling the gas pressure at the

burner accordingly.

VR..N

VMV

VG..L

ECOMAX

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

PDZ

DG

AKT

VAG

A system which includes air flow monitoring is also

recommended to monitor pre-purge (pursuant to

EN 746-2 and ISO 13577-2) even if there is a pneumatic

air/gas ratio control system.