3. Configuration

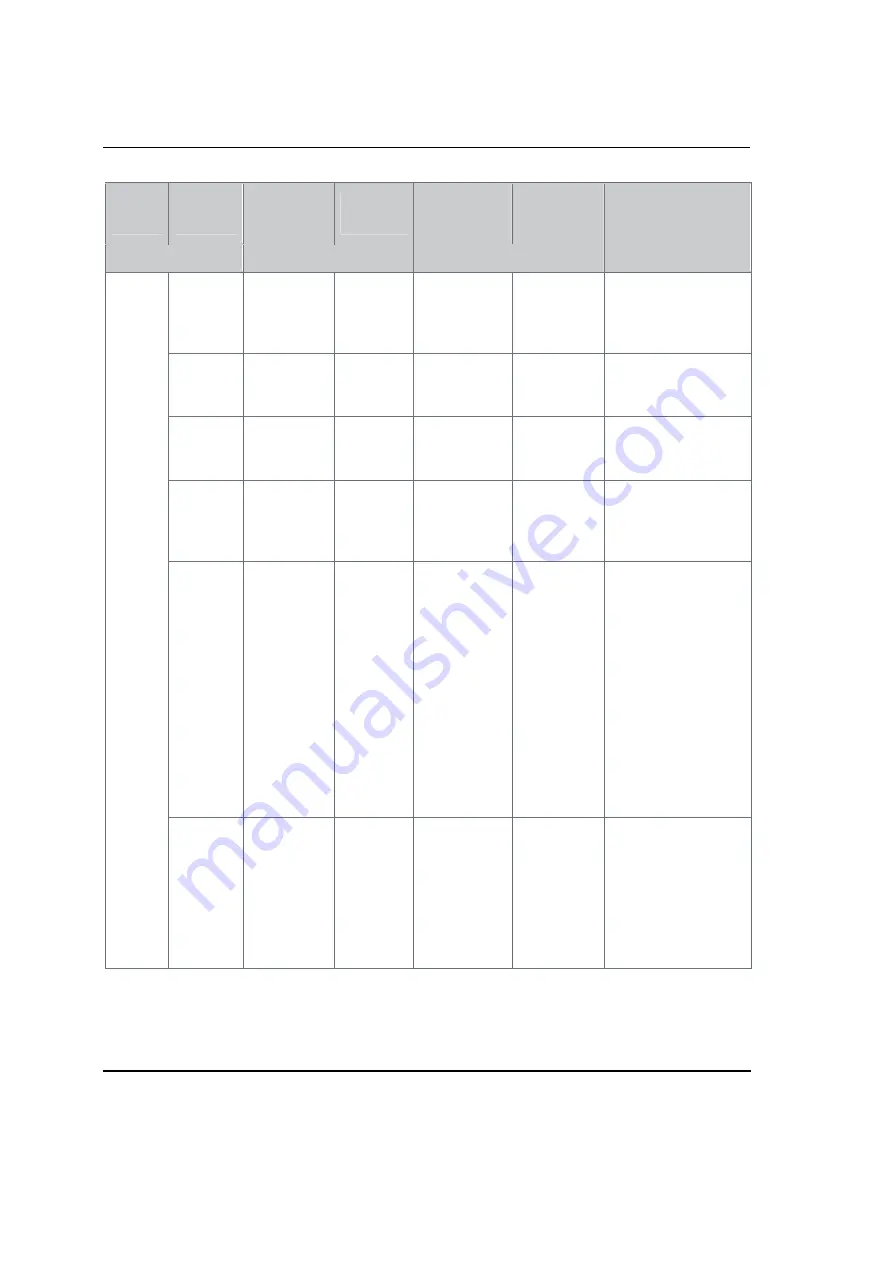

3.7. ALARM Set Up Group

34

EDC201 / EDC202 / EDC203 Product Manual

Revision 2.0

July 2015

Set up

Group

Function

Prompt

7-Segment

Code

Default

Value

Selection or

Range of

Setting

7-Segment

Code

Parameter

Definition

Top Display

Upper Display

Lower Display

Diagnostic

DIAG

SYSTEM

DIAGNOSTIC. This

configuration is not

available on EDC201.

22SEL

SE22

HIGH

HI

HIGH ALARM. This

configuration is not

available on EDC201.

LOW

LO

LOW ALARM. This

configuration is not

available on EDC201.

22VAL

VL22

-

-

ALARM 22 SET

POINT VALUE

。

This

configuration is not

available on EDC201.

ALHYST

HYSA

1%

0-100% OF

SPAN

ALARM

HYSTERESIS—A

single adjustable

hysteresis is provided

on alarms such that

when the alarm is OFF

it activates at exactly

the alarm Set Point;

when the alarm is ON,

it will not deactivate

until the variable is

0.0 % to 100 % away

from the alarm Set

Point.

ALARM

DELAY

DLYA

0

0 ~ 30s

Configurable alarm

trigger delay time

allows you to force the

trigger time of an alarm

to delay for a time

period of from 0 to 30

seconds in an alarm

condition.