Part No.: 44200004 - Revision 2

SVP Controller Operation Manual

4-1

CHAPTER 4 CALIBRATION

4.1 General

It is recommended that prior to doing any volumetric calibration that

the personnel involved read the API Manual of Petroleum Measurement

Standards (MPMS) Chapter 3 – Proving Systems sec 3.8, and the MPMS

Chapters 3.3.7.1, and 12.2.4 – pertaining to the calculation for the volume

of provers.

Although the prover may be calibrated with procedures traceable

to the National Institute of Standards and Technology (NIST) by a

number of techniques, only two techniques for volume determination

will be described here, a volumetric calibration and a gravimetric

(mass) calibration.

The gravimetric calibration method requires collecting the volume of water

displaced by the prover during a prove pass and determining its mass by

weighing it with a precision scale or balance. Corrections are made for the

density of the water and the buoyancy of the air displaced by the volume

of water per API 14.6, and applying various other correction factors such

as the temperature and pressure effects on the flow tube and the volume

switch position. De-ionized or distilled water should be utilized for the

gravimetric method. API 4.9.4 is the API standard used for the density

determination of water.

The displaced volume has been calibrated as described in the MPMS API

chapters,: 4.2, 4.9 and 12.2.4.

The Honeywell Enraf small volume prover base volume has been

determined at the factory. Recalibration is recommended either at 1 year

intervals, or as determined by the authorities and parties responsible for

the measurement. Recalibration is also required after any maintenance

which may affect the base volume, i.e.: complete switch bar replacement.

Honeywell Enraf small volume prover optical switches are field replaceable

and adjusted to an extremely high degree of precision. Individual switch

replacement does not necessitate re-calibration. See Section 6.7 for more

information on optical switches.

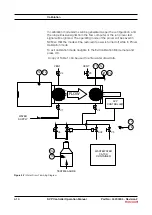

4.2 Static Leak Detection

The Honeywell Enraf static leak detection procedure should be used prior

to water draw or at any time that meter proof repeatability is difficult to

attain. It is not necessary to remove the prover from the process line to

perform a leak test. It is only necessary to block off the inlet and outlet of

the prover with it full of fluid. Block off the drain valves and verify there is

no leak path from the prover. If necessary, insert blind flanges into the inlet

and outlet ports to isolate the prover from the system. It is also necessary

to have a differential pressure gauge with a sufficient pressure rating to