EXCEL 10 W7751H SMART VAV ACTUATOR

5

95-7553—04

IMPORTANT

The minimum position set screw on the actuator is

not available on the W7751H device.

Fig. 8. Lifting a range stop pin out of its slot.

Piping

Air flow Pickup

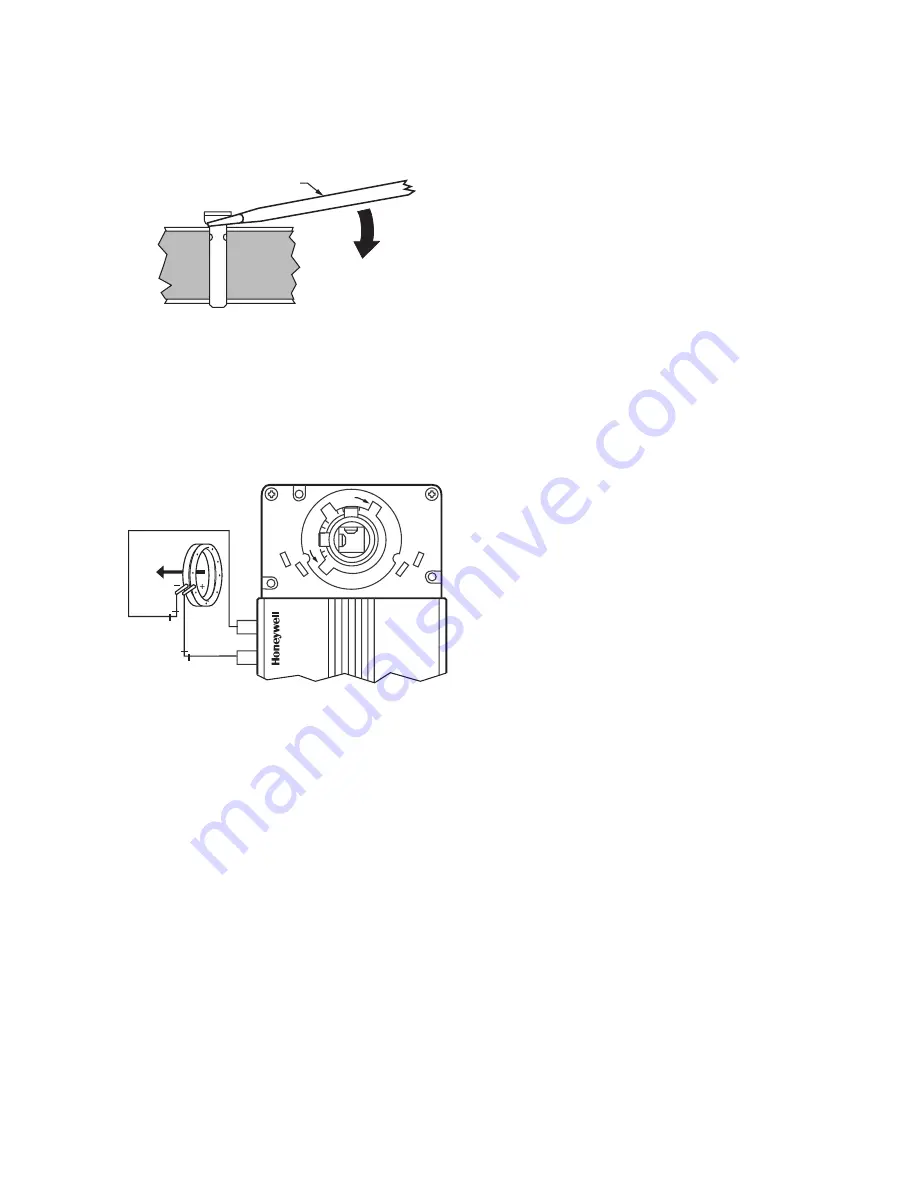

Connect the air flow pickup to the two connectors on the

controller of the W7751H. See Fig. 9.

Fig. 9. Smart VAV Actuator air flow pickup connections.

NOTES:

—

Use 1/4 in. (6 mm) outside diameter with 0.040 in.

(1 mm) wall thickness plenum rated 1219 FR

(94V-2) pneumatic tubing.

—

Always use a fresh cut on the end of the tubing

that connects to the air flow pickups and the

connectors on the VAV controllers.

Connect the high pressure or upstream tube to the plastic

restrictor labeled (+ HI) or P1 and the low pressure or

downstream tube to the restrictor labeled (- LO) or P2. See

labeling in Fig. 9.

NOTES:

—

If controllers are mounted in unusually dusty or

dirty environments, a 5-micron disposable air filter

is recommended for the high pressure line

(marked as +) connected to the air flow pickup.

—

When using twin tubing from pickup, split pickup

tubing a short length to accommodate connections.

—

Tubing from air flow pickup to VAV controller

should not exceed three feet (0.914m). Lengths

longer than this can degrade flow sensing

accuracy.

—

To prevent VAV air flow connector breakage, use

caution when removing tubing from it. Always pull

straight away from connector; never remove by

pulling at an angle.

Wiring

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

NOTES:

—

For multiple controllers operating from a single

transformer, the same side of the transformer

secondary must be connected to the same input

terminal in each controller and the ground

terminals (3 on the W7751H, 28 on the W7751B,

and 32 on the W7751D,F) must be connected to a

verified earth ground for each controller in the

group. See Fig. 10. (Controller configurations are

not necessarily limited to three devices, but the

total power draw including accessories cannot

exceed 100 VA when powered by the same

transformer. See System Engineering form

74-2949 for power wiring recommendations.)

—

All loads on an Excel 10 Controller must be

powered by a single transformer.

—

Keep the earth ground connection (terminal 3)

wire run as short as possible. Refer to Fig. 16.

—

Do

not

connect the analog ground terminal (5) to

earth ground. Refer to Fig. 16.

Power

The 24 Vac power from an energy limited Class II Power

Source must be provided to each Smart VAV Actuator. To

conform to Class II restrictions, transformers must not be

larger than 100 VA. The maximum current draw at 24 Vac is

1.25A.

IMPORTANT

— Power must be off prior to connecting to or removing

connections from output terminals 9 and 10.

— Use the heaviest gauge wire available, up to

14 AWG (2.0 mm

2

) with a minimum of 18 AWG

(1.0 mm

2

), for all power and earth ground wiring. For

nonplenum, open areas, run cables exposed (or in

conduit, if required).

— If the W7751H Smart VAV Actuator is used on

Heating and Cooling Equipment (UL 1995, US

only)

and the transformer primary power is more

than 150 volts, connect the transformer secondary to

earth ground, see Fig. 10.

NOTE: Maintain a three-inch (76 millimeter) separation

between Triac outputs and L

ON

W

ORKS

® Bus wiring

throughout installation.

Auxiliary Switches

The 201052A,B,C Auxiliary Switch can be used with the

W7751H. It allows for control of equipment external to the

actuator (for example, electric reheat coils or fan) at an

adjustable point in the stroke (from 0 to 90 degrees) of the

actuator. The 201052 Switch is field-added. Self-tapping

Phillips head screws are included with the switch. The switch

can be mounted only one way (see Fig. 11) with the switch

contacts pointed to the top of the actuator.

SCREWDRIVER

M2065

AIRFLOW

DP PICKUP

AIRFLOW

DIRECTION

M10003

– LO

+ HI

CCW

CCW

CW

CW

60

45

45

60