10. C300 Controller Troubleshooting

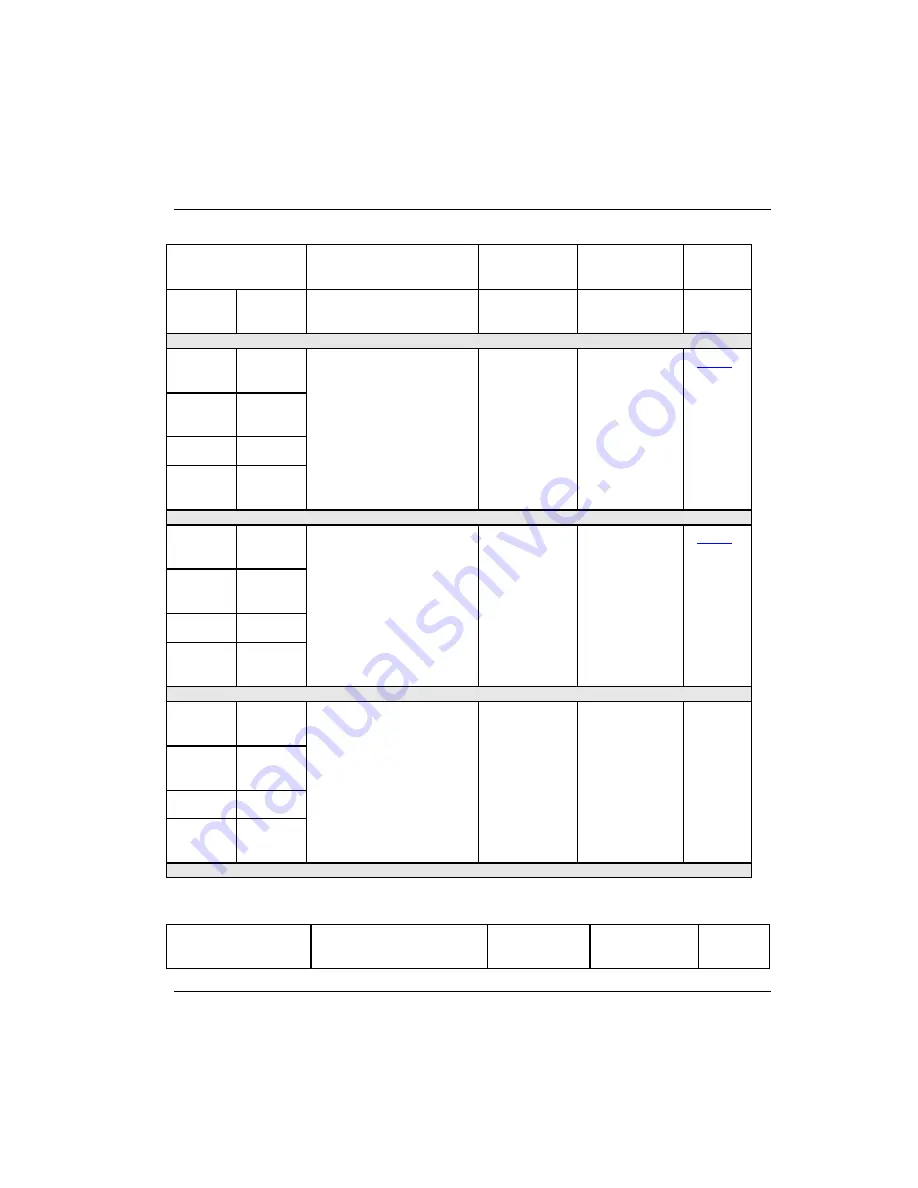

10.10. Communication and system time faults during startup

R500

April 2017

Series 8 C300 Controller User's Guide

Honeywell

267

Controller

Faceplate

Problem

C300 Block

Time Source

Station Alarm

Resolve

CB

icon

Grey

time source

Status

LED

Blinking

Orange

Communication on FTE

network

Communication

through CDA

Unable to establish

connection to system

time source

CDA

C300 Not

Synchronized

FTE

LEDs

Blinking

Green

Display

BKUP

CB

icon

Red ->

Blue

Status

LED

Blinking

Orange

Communication on FTE

network

No communication

through CDA

Established

connection to system

time source

SNTP

CDA

comm

Lost

Connectio

n

C300 Not

Synchroni

zed

FTE

LEDs

Blinking

Green

Display

BKUP

CB

icon

Grey

Status

LED

Blinking

Orange

None. Normal operation for

redundant secondary

controller with no battery

backup following a power

cycle.

SNTP

C300 Not

Synchronized

None.

FTE

LEDs

Blinking

Green

Display

BKUP

CB

icon

Yellow

Secondary C300 Controller with Memory Retention

Controller

Faceplate

Problem

C300 Block

Time Source

Station Alarm

Resolve