13.4 Fixing common problems

This section identifies some common problems and describes how you might fix them.

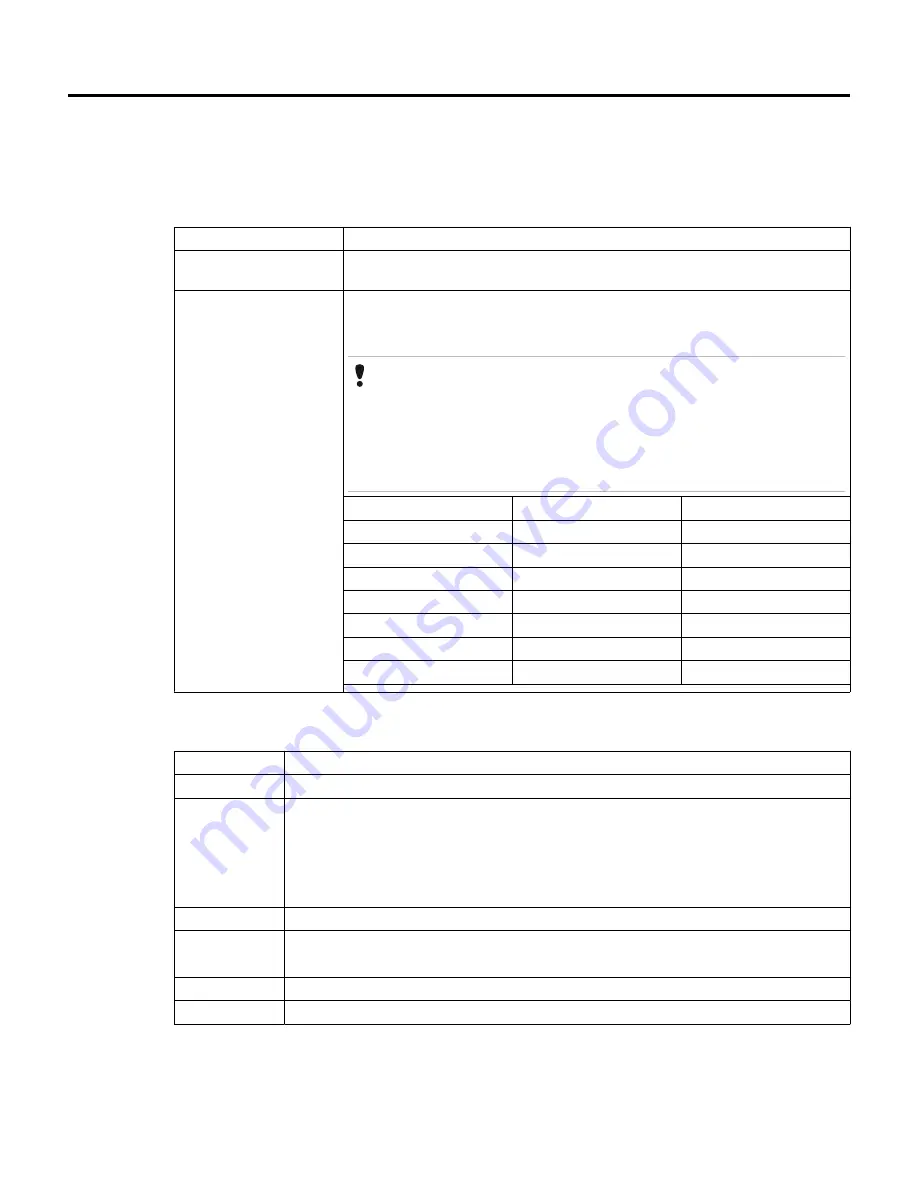

Loss of communication with the devices when a switchover is initiated

Diagnostic Check

Loss of communication with the slave devices when a switchover is initiated.

Cause

Probable PROFIBUS master configuration (bus parameters) errors. For example, Watchdog

Control Time and Data Control Time are not configured properly.

Solution

Modify the Watchdog Control Time and data control time based on the Baud Rate.

The following table lists the various Baud Rate and the recommended Watchdog Control

Time and the Data Control Time.

Attention

•

These values may differ based on the number of slave devices configured in the

network.

•

For the slave devices that have DP-V1 enabled, the Watchdog Control Time and

the Data Control Time must be three times longer than the actual time when DP-

V1 is disabled.

•

By default, the ET200M devices have DP-V1 enabled.

Baud Rate

Watchdog Control Time

Data Control Time

1500

1000

6000

500

1000

6000

187.5

2000

12000

93.75

3000

18000

45.45

4000

24000

19.2

5000

30000

9.6

6000

36000

Loss of connection to some of the field network slave devices

Diagnostic Check

Slave devices that are not communicating with the PGM have their status as "Bad."

Cause 1

Network or power supply wiring problems in the field network.

Solution

Open the Protocol Block detail displays to check the slave devices that are not communicating with

the PGM.

Obtain the field network wiring diagram and slave device power supply schematics.

Fix the problematic network wiring or power supply wiring manually.

Otherwise, go to Cause 2.

Cause 2

Slave devices are not configured properly.

Solution

Check for the slave device configurations and correct the configurations, if any.

Otherwise, go to Cause 3.

Cause 3

Slave devices are broken.

Solution

Replace the broken slave devices one by one.

13 PROFIBUS GATEWAY MODULE (PGM) TROUBLESHOOTING

256

www.honeywell.com

Summary of Contents for Experion PKS

Page 1: ...Experion PKS PROFIBUS Gateway Module User s Guide EPDOC XX88 en 431E June 2018 Release 431 ...

Page 8: ...CONTENTS 8 www honeywell com ...

Page 10: ...1 ABOUT THIS GUIDE 10 www honeywell com ...

Page 32: ...4 PROFIBUS GATEWAY MODULE PGM INSTALLATION 32 www honeywell com ...

Page 58: ...5 PROFIBUS GATEWAY MODULE PGM BLOCK 58 www honeywell com ...

Page 69: ...6 PROTOCOL BLOCK 69 ...

Page 103: ...5 Click OK 6 PROTOCOL BLOCK 103 ...

Page 110: ...6 PROTOCOL BLOCK 110 www honeywell com ...

Page 183: ...PDC Details tab Figure 6 Detail Display of PDC Details tab 7 DEVICE SUPPORT BLOCK DSB 183 ...

Page 186: ...7 DEVICE SUPPORT BLOCK DSB 186 www honeywell com ...

Page 231: ...9 PROFIBUS I O MODULE PIOMB FUNCTION BLOCK 231 ...

Page 232: ...9 PROFIBUS I O MODULE PIOMB FUNCTION BLOCK 232 www honeywell com ...

Page 236: ...10 PROFIBUS GATEWAY MODULE PGM CONFIGURATION EXAMPLE 236 www honeywell com ...

Page 264: ...13 PROFIBUS GATEWAY MODULE PGM TROUBLESHOOTING 264 www honeywell com ...